Abstract

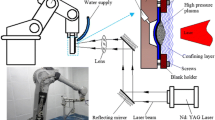

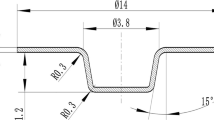

Laser shock forming (LSF) is a sheet plastic forming technology, which employs laser-induced shock waves to make sheet metal duplicate a desired shape of the mold. In this paper, a finite element analysis (FEA) model was developed to simulate dynamic forming process with the commercial finite element code ABAQUS/Explicit, and a series of dynamic deformation behaviors of the metal sheet shaped into conical cup at the end of different periods of time were displayed and discussed in detail. The springback of conical cup and the distribution of residual stress were analyzed with ABAQUS/Standard. All these investigations could provide insight into the physics process of the ultra-fast deformation. The LSF experiment was further conducted to verify the results predicted by FEA. The experiment results are well consistent with the numerical predicted data, which validates the FEA model. It indicates that FEA can be used to simulate the forming process and optimize its parameters.

Similar content being viewed by others

References

Kowsarinia E, Alizadeh Y, Pour HSS (2013) Theoretical and experimental study on the effects of explosive forming parameters on plastic wrinkling of annular plates. Int J Adv Manuf Technol 67(1–4):877–885

Jiang HW, Li N, Xu Z, Yan C, Wang DZ, Han XT (2015) Non-twinning deformation mechanism of pure copper under high speed electromagnetic forming. Mater Des 81:54–58

Wang X, Du DZ, Zhang H, Shen ZB, Liu HX, Zhou ZJ, Liu H, Hu Y, Gu CX (2013) Investigation of microscale laser dynamic flexible forming process-simulation and experiments. Int J Mach Tools Manuf 67:8–17

Yu CJ, Gao H, Yu HY, Jiang HQ, Cheng GJ (2009) Laser dynamic forming of functional materials laminated composites on patterned three-dimensional surfaces with applications on flexible microelectromechanical systems. Appl Phys Lett 95(9):091108

Li J, Chung TF, Chen YP, Cheng GJ (2002) Nanoscale strainability of graphene by laser shock-induced three-dimensional shaping. Nano Lett 12(9):4577–4583

O’Keefe JD, Skeen CH, York CM (1973) Laser-induced deformation modes in thin metal targets. J Appl Phys 44(10):4622–4626

Zhou JZ, Yang JC, Zhang YK, Zhou M (2002) A study on super-speed forming of metal sheet by laser shock waves. J Mater Process Technol 129(1–3):241–244

Niehoff HS, Vollertsen F (2005) Non-thermal laser stretch-forming. Adv Mater Res 6–8:433–440

Cheng GJ, Pirzada D, Zhou M (2007) Microstructure and mechanical property characterizations of metal foil after microscale laser dynamic forming. J Appl Phys 101(6):063108

Zheng C, Sun S, Ji Z, Wang W, Liu J (2010) Numerical simulation and experimentation of micro scale laser bulge forming. Int J Mach Tools Manuf 50(12):1048–1056

Yang CJ, Ye Z, Lu JZ, Jiang YF (2011) Laser shock forming of SUS304 stainless steel sheet with elliptical spot. Int J Adv Manuf Technol 56(9–12):987–993

Nagarajan B, Castagne S, Wang ZK (2013) Mold-free fabrication of 3D microfeatures using laser-induced shock pressure. Appl Surf Sci 268:529–534

Zhang XQ, She JP, Li SZ, Duan SW, Zhou Y, Yu XL, Zheng R, Zhang B (2015) Simulation on deforming progress and stress evolution during laser shock forming with finite element method. J Mater Process Technol 220:27–35

Zhang D, Lin YY, Gu CX, Shen ZB, Liu HX, Wang X (2015) A mold-free laser shock micro-drawing forming process using plasticine as the flexible support. Int J Adv Manuf Technol 79(1–4):265–272

Gao H, Ye C, Cheng GJ (2009) Deformation behaviors and critical parameters in microscale laser dynamic forming. J Manuf Sci Eng Trans ASME 131(5):051011

Liu HX, Shen ZB, Wang X, Wang HJ, Tao MK (2010) Micromould based laser shock embossing of thin metal sheets for MEMS applications. Appl Surf Sci 256(14):4687–4691

Li J, Cheng GJ (2010) Multiple-pulse laser dynamic forming of metallic thin films for microscale three dimensional shapes. J Appl Phys 108(1):013107

Jiang YF, Huang Y, Jin H, Gu YY, Ren AG, Huang LW, Qian XM (2013) Research on precision control of sheet metal forming by laser shock waves with semi-die. Opt Laser Technol 45(1):598–604

ABAQUS 6.11 Documentation, Dassault Systèmes Simulia Corp., Providence, RI, USA, 2011

Ding K, Ye L (2003) FEM simulation of two sided laser shock peening of thin sections of Ti-6Al-4V alloy. Surf Eng 19(2):127–133

Zhang XQ, Chen LS, Li SZ, Duan SW, Zhou Y, Huang ZL, Zhang Y (2015) Investigation of the fatigue life of pre- and post-drilling hole in dog-bone specimen subjected to laser shot peening. Mater Des 88:106–114

Correa C, Gil-Santos A, Porro JA, Díaz M, Ocãna JL (2015) Eigenstrain simulation of residual stresses induced by laser shock processing in a Ti6Al4V hip replacement. Mater Des 79:106–114

Fabbro R, Fournier J, Ballard P, Devaux D, Virmont J (1990) Physical study of laser-produced plasma in confined geometry. J Appl Phys 68(2):775–784

Zhou M, Zhang YK, Cai L (2003) Ultrahigh-strain-rate plastic deformation of a stainless-steel sheet with TiN coatings driven by laser shock waves. Appl Phys A Mater Sci Process 77(3–4):549–554

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high rates and high temperatures. In: Proceedings of the 7th international symposium on ballistics 547:541–547

Fan Y, Wang Y, Vukelic S, Yao YL (2005) Wave-solid interactions in laser-shocked-induced deformation processes. J Appl Phys 98(10):104904

Wang YN, Fan YJ, Vukelic S, Yao YL (2007) Energy-level effects on the deformation mechanism in microscale laser peen forming. J Manuf Process 9(1):1–12

Fang YW, Li YH, He WF, Lu YJ, Li PY (2013) Numerical simulation of residual stresses fields of DD6 blade during laser shock processing. Mater Des 43:170–176

Sagisaka Y, Kamiya M, Matsuda M, Ohta Y (2010) Thin-sheet-metal bending by laser peen forming with femtosecond laser. J Mater Process Technol 210(15):2304–2309

Risch D, Beerwald C, Brosius A, Kleiner M (2004) On the significance of the die design for the electromagnetic sheet metal forming. Proc. of the ICHSF 2004-1st International conference on High speed forming, Dortmund, pp.191–200

Ma XQ (1992) Shock dynamics. Beijing Institute of Technology Press

Aryaei A, Hashemnia K, Jafarpur K (2010) Experimental and numerical study of ball size effect on restitution coefficient in low velocity impacts. Int J Impact Eng 37(10):1037–1044

Vollertsen F (2013) Micro metal forming. Springer, Berlin Heidelberg

Wang R, Xiong ZH, Huang WB (1998) Fundament of plastic mechanics. Science Press, Beijing

Hu YQ, Zhao YP (2001) Scale effect of plastic strain rate. Chin J Aeronaut 14(1):37–43

Wagoner RH, Lim H, Lee MG (2013) Advanced issues in springback. Int J Plast 45:3–20

Parsa MH, Mohammadi SV, Aghchai AJ (2014) Al3105/polypropylene/Al3105 laminates springback in V-die bending. Int J Adv Manuf Technol 75(5–8):849–860

Papeleux L, Ponthot JP (2002) Finite element simulation of springback in sheet metal forming. J Mater Process Technol 125-126:785–791

Lee SW, Yang DY (1998) An assessment of numerical parameters influencing springback in explicit finite element analysis of sheet metal forming process. J Mater Process Technol 80-81:60–67

Zein H, Sherbiny ME, Abd-Rabou M, Shazly ME (2014) Thinning and spring back prediction of sheet metal in the deep drawing process. Mater Des 53:797–808

Shahabad SI, Naeini HM, Roohi AH, Soltanpour M, Tavakoli A (2016) Height prediction of dome-shaped products in laser forming process. Int J Adv Manuf Technol pp 1–10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Zhang, Y., Yin, Y. et al. Simulation of the forming process of conical cup shaped by laser-induced shock waves. Int J Adv Manuf Technol 91, 1619–1630 (2017). https://doi.org/10.1007/s00170-016-9633-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9633-x