Abstract

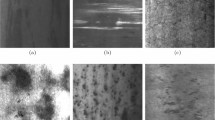

In this paper, ultrasonic echo signals of four kinds of stainless steel resistance spot welds, namely failed weld, stick weld, good weld, and defective weld with gas pore, are analyzed in the time domain, frequency domain, and time-frequency domain based on wavelet packet transform. Fourteen ultrasonic characteristic signals which can reflect the different kinds of spot welds are extracted and can be automatically identified and classified by back-propagation (BP) neural network. The method of this paper can realize the intelligent identification of resistance spot welding defects, and the feasibility of this method has been verified in the experiment.

Similar content being viewed by others

References

Bina MH, Jamali M, Shamanian M, Sabet H (2014) Investigation on the resistance spot-welded austenitic/ferritic stainless steel. Int J Adv Manuf Technol 75(9):1371–1379. doi:10.1007/s00170-014-6220-x

Zhang H, Hou Y, Zhang J, Wang F (2015) A new method for nondestructive quality evaluation of the resistance spot welding based on the radar chart method and the decision tree classifier. Int J Adv Manuf Technol 78(5):841–851. doi:10.1007/s00170-014-6654-1

Min J (2003) Real time monitoring weld quality of resistance spot welding for the fabrication of sheet metal assemblies. J Mater Process Technol 132(1–3):102–113. doi:10.1016/S0924-0136(02)00409-0

Agashe S, Zhang H (2003) Selection of schedules based on heat balance in resistance spot welding. Weld J 82(7):179–183

El-Banna M, Filev D, Chinnam RB (2008) Online qualitative nugget classification by using a linear vector quantization neural network for resistance spot welding. Int J Adv Manuf Technol 36(3):237–248. doi:10.1007/s00170-006-0835-5

Podržaj P, Simončič S (2011) Resistance spot welding control based on fuzzy logic. Int J Adv Manuf Technol 52(9):959–967. doi:10.1007/s00170-010-2794-0

Luo Y, Liu JH, Xu HB, Xiong CZ, Liu L (2009) Regression modeling and process analysis of resistance spot welding on galvanized steel sheet. Mater design 30(7):2547–2555. doi:10.1016/j.matdes.2008.09.031

Ruisz J, Biber J, Loipetsberger M (2007) Quality evaluation in resistance spot welding by analysing the weld fingerprint on metal bands by computer vision. Int J Adv Manuf Technol 33(9):952–960. doi:10.1007/s00170-006-0522-6

Karimi MR, Sedighi M, Afshari D (2015) Thermal contact conductance effect in modeling of resistance spot welding process of aluminum alloy 6061-T6. Int J Adv Manuf Technol 77(5):885–895. doi:10.1007/s00170-014-6492-1

Kaya Y, Kahraman N (2011) The effects of electrode force, welding current and welding time on the resistance spot weldability of pure titanium. Int J Adv Manuf Technol 60(1):127–134. doi:10.1007/s00170-011-3604-z

Zhou K, Cai LL (2013) Online nugget diameter control system for resistance spot welding. Int J Adv Manuf Technol 68(9):2571–2588. doi:10.1007/s00170-013-4886-0

Chen ZH, Shi YH, Jiao BQ, Zhao HY (2009) Ultrasonic nondestructive evaluation of spot welds for zinc-coated high strength steel sheet based on wavelet packet analysis. J Mater Process Technol 209(5):2329–2337. doi:10.1016/j.jmatprotec.2008.05.030

Ben BS, Yang SH, Ratnam C, Ch Ben BA (2013) Ultrasonic based structural damage detection using combined finite element and model Lamb wave propagation parameters in composite materials. Int J Adv Manuf Technol 67(5):1847–1856. doi:10.1007/s00170-012-4613-2

Zhou GH, Xu GC, Gu XP, Liu J (2015) Research on evaluating laser welding quality based on two-dimensional array ultrasonic probe. Int J Adv Manuf Technol 84(5):1717–1723. doi:10.1007/s00170-015-8243-3

Ditchburn RJ, Burke SK, Scala CM (1996) NDT of welds: state of the art. NDT & Int 29(2):111–117. doi:10.1016/0963-8695(96)00010-2

Blomme E, Bulcaen D, Declercq F (2002) Air-coupled ultrasonic NDE: experiments in the frequency range 750 kHz-2 MHz. NDT & Int 35(7):417–426. doi:10.1016/S0963-8695(02)00012-9

Chertov AM, Maev RG, Severin FM (2007) Acoustic microscopy of internal structure of resistance spot welds. IEEE T Ultrason Ferr 54(8):1521–1529. doi:10.1109/TUFFC.2007.422

Thornton M, Han L, Shergold M (2012) Progress in NDT of resistance spot welding of aluminium using ultrasonic C-scan. NDT & Int 48(2):30–38. doi:10.1016/j.ndteint.2012.02.005

Denisov AA, Shakarji CM, Lawford BB, Maev RG, Paille JM (2004) Spot weld analysis with 2D ultrasonic arrays. J Res Natl Inst Stan 109(2):233–244. doi:10.6028/jres.109.015

Liu J, Xu GC, Gu XP, Zhou GH (2015) Ultrasonic test of resistance spot welds based on wavelet package analysis. Ultrasonics 56:557–565. doi:10.1016/j.ultras.2014.10.013

Lee HT, Wang M, Maev R, Maeva E (2003) A study on using scanning acoustic microscopy and neural network techniques to evaluate the quality of resistance spot welding. Int J Adv Manuf Technol 22(9):727–732. doi:10.1007/s00170-003-1599-9

Gang T, Takahashi Y, Wu L (2013) Intelligent pattern recognition and diagnosis of ultrasonic inspection of welding defects based on neural network and information fusion. Sci Technol Weld Joi 7(5):314–320. doi:10.1179/1362171022250044310

Sambath S, Nagaraj P, Selvakumar N (2011) Automatic defect classification in ultrasonic NDT using artificial intelligence. J Nondestruct Eval 30(1):20–28. doi:10.1007/s10921-010-0086-0

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, J., Xu, G., Ren, L. et al. Defect intelligent identification in resistance spot welding ultrasonic detection based on wavelet packet and neural network. Int J Adv Manuf Technol 90, 2581–2588 (2017). https://doi.org/10.1007/s00170-016-9588-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9588-y