Abstract

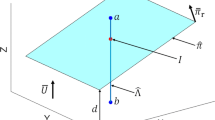

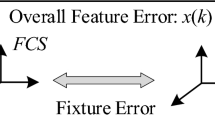

Stream of variation (SoV) model is an effective tool, which can describe the dimensional variation and propagation for multistage machining processes. Compared with traditional single-stage error models considering errors from a single machining stage only, SoV model can depict the complicated interactions between different errors at different stages. This paper reviews three major linearized SoV modeling methods for multistage machining processes based on the literature published over the last two decades. These three linearized SoV modeling methods are based on differential motion vectors, equivalent fixture error, and kinematic analysis, respectively. Each method has its corresponding advantages and disadvantages. The model using differential motion vector (DMV) concept from robotics incorporates fixture-, datum-, and machining-induced variations in the multistage variation propagation for orthogonal 3-2-1 fixturing layout while the primary datum deviation is currently overlooked. The kinematic analysis method can address general fixture layouts rather than being limited to orthogonal 3-2-1 fixture layouts. The variation propagation model using the equivalent fixture error concept can directly model the process physics regarding how fixture, datum, and machine tool errors generate the same pattern on the features of the workpiece. The results of these three models with respect to an example are also given to make a comparison. Finally, a perspective overview of the future research about SoV methods is presented.

Similar content being viewed by others

Reference

Kreng VB, Liu CR, Chu CN (1994) A kinematic model for machine tool accuracy characterization. Int J Adv Manuf Technol 9:79–86

Lee ES, Suh SH, Shon JW (1998) A comprehensive method for calibration of volumetric positioning accuracy of CNC-machines. Int J Adv Manuf Technol 14:43–49

Chen G, Yuan J, Ni J (2001) A displacement measurement approach for machine geometric error assessment. Int J Mach Tools Manuf 41:149–161

Okafor AC, Ertekin YM (2000) Derivation of machine tool error models and error compensation procedure for three axes vertical machining center using rigid body kinematics. Int J Mach Tools Manuf 40:1199–1213

Ni J, Wu SM (1993) An on-line measurement technique for machine volumetric error compensation. ASME Trans J Eng Ind 115:85–92

Fuh J, Chang C, Melkanoff M (1993) An integrated fixture planning and analysis system for machining processes. Robot Comput Integr Manuf 10(5):339–353

Meter ECD (1995) Min-max load model for optimizing machining fixture performance. ASME Trans J Eng Ind 117:186–193

Rong Y, Bai Y (1996) Machining accuracy analysis for computer-aided fixture design verification. ASME Trans J Manuf Sci Eng 18: 289–299

Hockenberger MJ, Meter ECD (1996) The application of meta functions to the quasi-static analysis of workpiece displacement within a machining fixture. ASME Trans J Manufact Sci Eng 118: 325–331

Cai W, SJ H, Yuan J (1997) A variational method of robust fixture configuration design for 3-D workpieces. J Manuf Sci Eng 119:593–602

Lee JH, Yang SH (2002) Statistical optimization and assessment of a thermal error model for CNC machine tools. Int J Mach Tools Manuf 42(1):147–155

Mize CD, Ziegert JC (2000) Neural network thermal error compensation of a machining center. Precision Eng 24(4):338–346

Yang J, Yuan J, Ni J (1999) Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. Int J Mach Tools Manuf 39(9):1367–1381

Lo C, Yuan J, Ni J (1999) Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. Int J Mach Tool Manufact 39(9):1383–1396

Yang J, Yuan J, Ni J (1997) Real-time cutting force induced error compensation on a turning center. Int J Mach Tools Manuf 37(11):1597–1610

Chen SG, Ulsoy AG, Koren Y (1998) Error source diagnostics using a turning process simulator. ASME Trans J Manuf Sci Eng 120: 409–416

Mayer JR, Phan AV, Cloutier G (2000) Prediction of diameter errors in bar turning: a computationally effective model. Appl Math Model 24:943–956

Ramesh R, Mannan MA, Poo AN (2000a) Error compensation in machine tools-a review part I: geometric, cutting-force induced and fixture dependent errors. Int J Mach Tools Manuf 40:1235–1256

Ramesh R, Mannan MA, Poo AN (2000b) Error compensation in machine tools—a review part II: thermal errors. Int J Mach Tools Manuf 40:1235–1256

Yao J, Jiao Z, Ma D (2014) Extended-state-observer-based output feedback nonlinear robust control of hydraulic systems with backstepping. IEEE Trans Ind Electron 61(11):6285–6293

Yao J, Jiao Z, Yao B (2012) Robust control for static loading of electro-hydraulic load simulator with friction compensation. Chin J Aeronaut 25:954–962

Liu J (2010) Variation reduction for multistage manufacturing processes: a comparison survey of statistical-process-control vs stream-of-variation methodologies. Qual Reliab Eng Int 26:645–661

Mantripragada R, Whitney DE (1999) Modeling and controlling variation propagation in mechanical assemblies using state transition models. IEEE Trans Robot Automat 15:124–140

Lawless JF, Mackay RJ, Robinson JA (1999) Analysis of variation transmission in manufacturing processes—part I. J Qual Technol 31(2):131–142

Agrawal R, Lawless JF, Mackay RJ (1999) Analysis of variation transmission in manufacturing processes—part II. J Qual Technol 31(2):143–154

Huang W, Lin J, Kong Z, Ceglarek D (2007) Stream-of-variation (SOVA) modeling II: a generic 3D variation model for rigid body assembly in multi-station assembly processes. ASME Trans J Manuf Sci Eng 129(4):832–842

Huang W, Lin J, Bezdecny M, Kong Z, Ceglarek D (2007) Stream-of-variation modeling I: a generic 3D variation model for rigid body assembly in single station assembly processes. ASME Trans J Manuf Sci Eng 129(4):821–831

Liu J, Jin J, Shi J (2010) State space modeling for 3-D variation propagation in rigid-body multistage assembly processes. IEEE Trans Autom Sci Eng 7(2):274–290

Jin J, Shi J (1999) State space modeling of sheet metal assembly for dimensional control. J Manuf Sci Eng 121:756–762

Zhao J, Liang J, Xue P (2011) Analysis and modeling of variation transmission in multi-stage manufacturing process. J Lanzhou Univ of Tech 37(3):28–33

Ding Y, Ceglarek D, Shi J (2000) Modeling and diagnosis of multistage manufacturing process: Part I State space model. In: Proceedings of 2000 Japan-USA Symposium on Flexible Automation, Ann Arbor, USA

Huang Q, Shi J (2004) Stream of variation modeling and analysis of serial-parallel multistage manufacturing systems. ASME Trans J Manuf Sci Eng 126: 611–618

Xie K, Wells L, Camelio J, Youn BD (2007) Variation propagation analysis on compliant assemblies considering contact interaction. ASME Trans J Manuf Sci Eng 129(1):934–942

Camelio J, Hu SJ, Ceglarek D (2003) Modeling variation propagation of multi-station assembly systems with complaint parts. ASME Trans J Mech Des 125:673–681

Huang Q, Zhou N, Shi J (2000) Stream of variation modeling and diagnosis of multi-station machining processes. In: Proceedings of IMECE, International Mechanical Engineering Congress & Exposition 11:81–88

Zhong W, Huang Y, Hu SJ (2002) Modeling variation propagation in machining systems with different configurations. In: ASME International Mechanical Engineering Congress & Exposition, pp 97–106

Djurdjanovic D, Ni J (2001) Linear state space modeling of dimensional machining errors. Trans NAMRI/SME, pp541–548

Liu D, Jiang P (2009) Modeling of machining error flow based on form features for multistage processes. Int J Comp Integr Manuf 22(9):857–876

Shi J, Zhou S (2009) Quality control and improvement for multistage systems: a survey. IIE Trans 41:744–753

Zhou S, Huang Q, Shi J (2003) State space modeling of dimensional variation propagation in multistage machining process using differential motion vectors. IEEE Trans Robot Autom 19(2):296–309

Zhou S, Chen Y, Ding Y, Shi J (2003) Diagnosability study of multistage manufacturing processes based on linear mixed effects models. Technometrics 45:312–325

Abellan-Nebot JV, Liu J, Romero F (2012) State space modeling of variation propagation in multistation machining processes considering machining-induced variations. J Manuf Sci Eng-Trans of the ASME 134(2):1–13

Abellan-Nebot JV, Liu J (2013) Variation propagation modeling for multi-station machining processes with fixtures based on locating surfaces. Int J Prod Res 51(15):4667–4681

Loose JP, Zhou S, Ceglarek D (2007) Kinematic analysis of dimensional variation propagation for multistage machining processes with general fixture layouts. IEEE Trans Autom Sci Eng 4:141–152

Wang H, Huang Q, Katz R (2005) Multi-operational machining processes modeling for sequential root cause identification and measurement reduction., J Manuf Sci Eng Trans of the ASME 127:512–521

Abellan-Nebot JV, Subirón FR, Mira JS (2013) Manufacturing variation models in multi-station machining systems. Int J Adv Manuf Technol 64:63–83

Liu J, Shi J, SJ H (2009) Quality-assured setup planning based on the stream-of-variation model for multi-stage machining processes. IIE Trans 41(4):323–334

Zhang M, Djurdjanovic D, Ni J (2007) Diagnosibility and sensitivity analysis for multi-station machining processes. Int J Mach Tools Manuf 47:646–657

Djurdjanovic D, Ni J (2003) Bayesian approach to measurement scheme analysis in multistation machining systems. Proc Inst Mech Eng B J Eng Manuf 217:1117–1130

Djurdjanovic D, Ni J (2004) Measurement scheme synthesis in multi-station machining systems. J Manuf Sci Eng 126:178–188

Djurdjanovic D, Ni J (2006) Stream-of-variation (SoV)-based measurement scheme analysis in multistation machining systems. IEEE Trans Autom Sci Eng 3:407–422

Qin Y, Zhao L, Yao Y, Xu D (2011) Multistage machining processes variation propagation analysis based on machining processes weighted network performance. Int J Adv Manuf Technol 55(5):487–499

Abellan-Nebot JV, Liu J, Subiron FR (2013) Process-oriented tolerancing using the extended stream of variation model. Comput Ind 6:485–498

Jiao Y, Djurdjanovic D (2010) Joint allocation of measurement points and controllable tooling machines in multistage manufacturing processes. IIE Trans 42:703–720

Abellan-Nebot JV, Liu J, Subiron FR (2012) Quality prediction and compensation in multi-station machining processes using sensor-based fixtures. Robot Comput-Integr Manuf 28:208–219

Paul RP (1981) Robot manipulators: mathematics, programming, and control. MIT Press, Cambridge, MA

Du S, Yao X, Huang D (2015) Engineering model-based Bayesian monitoring of ramp-up phase of multistage manufacturing process. Int J Prod Res 53(15):4594–4613

Du S, Yao X, Huang D, Wang M (2015) Three-dimensional variation propagation modeling for multistage turning process of rotary workpieces. Comput Ind Eng 82:41–53

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Jin, S. & Li, Z. A comprehensive study of linear variation propagation modeling methods for multistage machining processes. Int J Adv Manuf Technol 90, 2139–2151 (2017). https://doi.org/10.1007/s00170-016-9490-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9490-7