Abstract

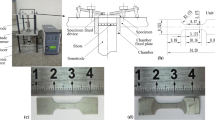

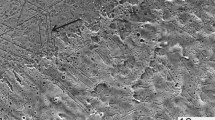

Ultrasonic shot peening (USP) is a mechanical surface treatment to rapidly realize surface nanocrystallization of metals. In this paper, the influence rules and mechanism of process parameters of USP on surface nanocrystallization and hardness of pure titanium were studied. Significant hardness increases of different degrees were observed, and nanocrystalline (NC) layers of different thicknesses and grain sizes were obtained on the surface of pure titanium after USP treatments with different process parameters, including peening duration, shot diameter, sonotrode amplitude, and peening distance. The influence rules of process parameters on the NC layers and surface hardness of peened pure titanium were analyzed with experimental results measured by Vickers microhardness meter, optical microscope (OM), scanning electron microscope (SEM), X-ray diffraction pattern (XRD), and high-resolution transmission electron microscope (HRTEM). After the influence mechanism of process parameters was discussed, a relationship expression was identified between the surface hardness of pure titanium treated by USP and the process parameters with a correlation coefficient equal to 0.998.

Similar content being viewed by others

References

Lu K, Lu J (1999) Surface nanocrystallization (SNC) of metallic materials—presentation of the concept behind a new approach. J Mater Sci Technol 15:193–197

Lu J, Peyre P, Oman Nonga C, Benamar A, Flavenot JF (1994) Proceedings of the fourth international conference on residual stresses. Society for Experimental Mechanics Baltimore, MD, USA, p 1154

Tao NR, Sui ML, Lu J, Lu K (1999) Surface nanocrystallization of iron induced by ultrasonic shot peening. Nanostruct Mater 11:433–440

Abramov VO, Sommer F, Gradov OM, Smirnov OM (1998) Surface hardening of metals by ultrasonically accelerated small metal balls. Ultrasonics 36:1013–1019

Liu G, Lu J, Lu K (2000) Surface nanocrystallization of 316L stainless steel induced by ultrasonic shot peening. Mater Sci Eng A 286:91–95

Li Y, Wang F, Liu G (2001) Grain - Size effect on the electrochemical corrosion of surface nanocrystallized low carbon steel. J Chinese Soc Corrosion Prot 21:219–223

Zhang JB, Liu YL, Zhao XQ, Wu J, Song HW, Xiong TY (2005) Microstructures and microhardness of SNCed medium carbon low alloy steels. Mater Sci Forum 475–479:137–140

Wu X, Tao N, Hong Y, Xu B, Lu J, Lu K (2002) Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of AL-alloy subjected to USSP. Acta Mater 50:2075–2084

Li K, He Y, Fang C, Ma H, Kim J, Lee HS, Song JI et al (2014) Surface nanocrystallization of pure Cu induced by ultrasonic shot peening. J Nanosci Nanotechnol 14:9637–9643

Wei YG, Wu XL, Zhu C, Zhao MH (2007) Microstructure and microhardness in surface-nanocrystalline Al-alloy material. In: Multiscaling in molecular and continuum mechanics: interaction of time and size from macro to nano: application to biology, physics, material science, mechanics, structural and processing engineering., pp 369–387

Lee HS, Kim DS, Jung JS, Pyoun YS, Shin K (2009) Influence of peening on the corrosion properties of AISI 304 stainless steel. Corros Sci 51:2826–2830

Cherif A, Pyoun Y, Scholtes B (2010) Effects of ultrasonic nanocrystal surface modification (UNSM) on residual stress state and fatigue strength of AISI 304. J Mater Eng Perform 19:282–286

Zhu XL, Lu XF, Ling X (2011) Errosion-corrosion critical performance of surface nanocrystalline 20 carbon steel in condensate water. Adv Mater Res 189-193:958–964

Rai PK, Pandey V, Chattopadhyay K, Singhal LK, Singh V (2014) Effect of ultrasonic shot peening on microstructure and mechanical properties of high-nitrogen austenitic stainless steel. J Mater Eng Perform 23:4055–4064

Eylon D, Seagle SR (2000) Advances in titanium technology—an overview. J Japan Inst Light Met 50:359–370

Niinomi M (2008) Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater 1:30–42

Jindal S, Bansal R, Singh BP, Pandey R, Narayanan S, Wani MR, Singh V (2014) Enhanced osteoblast proliferation and corrosion resistance of commercially pure titanium through surface nanostructuring by ultrasonic shot peening and stress relieving. J Oral Implantol 40:347–355

Mordyuk BN, Prokopenko GI (2006) Fatigue life improvement of alpha-titanium by novel ultrasonically assisted technique. Mater Sci Eng A 437:396–405

Suh MS, Pyoun YS, Sun CM (2012) Variation of fatigue properties in nanoskinned Ti-6Al-4V—rotating bending and axial loading tension-compression cycle-. Trans Korean Soc Mech Eng, A 36:443–449

Zhang C, Xie G, Wang Y, He X (2014) Microstructure evolution of TC4 alloy during nanocrystallization process. Rare Metal Mater Eng 43:2682–2686

Deng ZN, Liu JS, He Y, Wang SQ, Ma JF (2013) Synthesis and properties of hydroxyapatite-containing porous titania coating on titanium by ultrasonic shot peening and micro-arc oxidation. Adv Mater Res 690-693:2081–2084

Guo FA, Trannoy N, Lu J (2004) Analysis of thermal properties by scanning thermal microscopy in nanocrystallized iron surface induced by ultrasonic shot peening. Mater Sci Eng A 369:36–42

Nouguier-Lehon C, Zarwel M, Diviani C, Hertz D, Zahouani H, Hoc T (2013) Surface impact analysis in shot peening process. Wear 302:1058–1063

Sandá A, García Navas V, Gonzalo O (2011) Surface state of Inconel 718 ultrasonic shot peened: effect of processing time, material and quantity of shot balls and distance from radiating surface to sample. Mater Des 32:2213–2220

Badreddine J, Rouhaud E, Micoulaut M, Remy S (2014) Simulation of shot dynamics for ultrasonic shot peening: effects of process parameters. J Mater Eng Perform 82:179–190

Badreddine J, Rouhaud E, Micoulaut M, Retraint D, Remy S, Francois M, Viot P et al (2011) Simulation and experimental approach for shot velocity evaluation in ultrasonic shot peening. Mecanique Ind 12:223–229

SAE Standard J2277 (2009) Surface enhancement division—shot peening coverage determination

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22–31

Müller P, Trüe M, Böttcher R, Tomas J (2015) Acoustic evaluation of the impact of moist spherical granules and glass beads. Powder Technol 278:138–149

Munroe N, Tan X, Gu H (1997) Orientation dependence of slip and twinning in HCP metals. Scr Mater 36:1383–1386

Zhang ZF, Gu HC, Tan XL (1998) Low-cycle fatigue behaviors of commercial-purity titanium. Mater Sci Eng A 252:85–92

Kim I, Kim J, Shin DH, Liao XZ, Zhu YT (2003) Deformation twins in pure titanium processed by equal channel angular pressing. Scr Mater 48:813–817

Wen AL, Ren RM, Wang SW, Nishida SI (2004) Effect of surface nano-crystallization on microstructure and mechanic properties of commercial pure titanium. Key Eng Mater [Z] 261-263:1605–1610

Jiang XP, Wang XY, Li JX, Li DY, Man CS, Shepard MJ, Zhai T (2006) Enhancement of fatigue and corrosion properties of pure Ti by sandblasting. Mater Sci Eng A 429:30–35

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scr Mater 51:801–806

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Guan, Y., Wang, Y. et al. Influence of process parameters of ultrasonic shot peening on surface nanocrystallization and hardness of pure titanium. Int J Adv Manuf Technol 89, 1451–1468 (2017). https://doi.org/10.1007/s00170-016-9181-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9181-4