Abstract

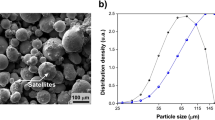

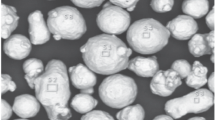

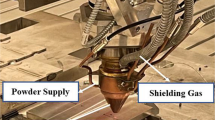

Direct laser powder deposition (DLPD) is a laser process that can produce fully dense components from powders for production and repairing purposes. Marages are high-strength steels that are hardened through ageing treatment. This work presents a study which integrated the numerical and experimental approaches, for the evaluation of the properties of 18 Ni (300) laser deposited marage powder. The powder was deposited onto AISI 304 substrate by a CO2 laser. During the experiments, laser power, scanning speed, powder flow rate and degree of overlapping varied according to a Taguchi plan. In particular, the degree of overlapping between adjacent layers and between successive tracks was calculated using an analytical model. Density, porosity, dilution, microstructure, adhesion to the substrate and microhardness of multilayer samples were evaluated using statistical algorithms. Both clad-substrate and clad-clad interfaces were characterised by metallographic and SEM analysis. High-density samples, with a satisfactory level of porosity, for successful additive and part repair applications, were fabricated through the method proposed and characterised in this paper.

Similar content being viewed by others

References

ASTM F2792-12a (2012) Standard terminology for additive manufacturing technology. ASTM International, West Conshohocken, Pennsylvania

Sears JW (1999) Direct laser powder deposition-state of the art, powder materials: current research and industrial practices. In: Marquis FDS, Editor. Proceedings of the 1999 Fall TMS Meeting, pp 213–226.

Toyserkani E, Khajepour A, Corbin SF (2005) Laser cladding. CRC Press, Boca Raton, Florida

Lu ZL, Li DC, Tong ZQ, Lu QP, Traore MM, Zhang AF, et al. (2011) Investigation into the direct laser forming process of steam turbine blade. Opt Lasers Eng 49:1101–1110

Peng L, Shengqin J, Xiaoyan Z, Qianwu H, Weihao X (2007) Direct laser fabrication of thin-walled metal parts under open-loop control. Int J Mach Tools Manuf 47:996–1002

Boisselier D, Sankaré S, Engel T (2014) Improvement of the laser direct metal deposition process in 5-axis configuration. Phys Procedia 56:239–249

Lewis GK, Schlienger E (2000) Practical considerations and capabilities for laser assisted direct metal deposition. Mater Des 21:417–423

Milewski JO, Lewis GK, Thoma DJ, Keel GI, Nemec RB, Reinert RA (1998) Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J Mater Process Technol 75(1–3):65–172

Bi G, Gasser A (2011) Restoration of nickel-base turbine blade knife-edges with controlled laser aided additive manufacturing. Phys Procedia 12:402–409

Wilson JM, Piya C, Shin YC, Zhao F, Ramani K (2014) Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J Clean Prod 80:170–178

Wang L, Pratt P, Felicelli SD, El Kadiri H, Berry JT, Wang PT et al (2009) Pore formation in laser-assisted powder deposition process. J Manuf Sci Eng Trans ASME 131.

Susan DF, Puskar JD, Brooks JA, Robino CV (2006) Quantitative characterization of porosity in stainless steel LENS powders and deposits. Mater Charact 57:36–43

Albaut GN, Grigor’ev-Golubev VV, Morozov NF, Proskura AV (1999) Influence of circular pores on the intensity of stresses. Mater Sci 35:76–81

Yan Y, Nash GL, Nash P (2013) Effect of density and pore morphology on fatigue properties of sintered Ti–6Al–4V. Int J Fatigue 55:81–91

Zhong C, Gasser A, Schopphoven T, Poprawe R (2015) Experimental study of porosity reduction in high deposition-rate laser material deposition. Opt Laser Technol 75:87–92

Chan KS, Lee Y-D (2008) Effects of deformation-induced constraint on high-cycle fatigue in Ti alloys with a duplex microstructure. Metall Mater Trans A 39:1665–1675

Sun G, Bhattacharya S, Dinda GP, Dasgupta A, Mazumder J (2011) Microstructure evolution during laser-aided direct metal deposition of alloy tool steel. Scr Mater 64:454–457

Zhang Y, Yu G, He X, Ning W, Zheng C (2012) Numerical and experimental investigation of multilayer SS410 thin wall built by laser direct metal deposition. J Mater Process Technol 212:106–112

ASM Handbook, Volume 1 properties and selection: irons, steels and high performance alloys (1990) ASM International, The Materials Information Company, United States of America, 1303, 1225–1236.

Lewis SR, Lewis R, Fletcher DI (2015) Assessment of laser cladding as an option for repairing/enhancing rails. Wear 330-331:581–591

Bergant Z, Grum J (2014) Heat treatment effects of laser cladded 12 Ni marage tool steel with Ni-Co-Mo alloys. J Heat Treat Mater 69(2):114–123

Bergant Z, Grum J (2014) The influence of chemical composition on residual stresses in NiCoMo alloy deposits on 12 Ni marage steel. Mater Sci Forum 768-769:449–455

Bergant Z, Grum J (2013) Influence of laser deposition technique on surface integrity of 12 Ni marage tool steel. Int J Microstruct Mater Prop 8(1–2):17–26

Zoran B, Marko SJ, Luis OJ, Janez G (2011) Laser cladding and heat treatment of Ni-Co-Mo marage steel. J ASTM Int 8(5).

Clare A, Olusola O, Folkes J, Farayibi P (2011) Laser cladding for railway repair and preventative maintenance. In: ICALEO 2011—Proceedings of 30th International Congress on Applications of Lasers and Electro-Optics: Laser Institute of America, pp 240–249.

Schwam D, Denney P, Kottman M (2014) Rejuvenation of steel dies with hot wire laser cladding. Trans N Amer Manufac 42(January):202–210

Shamsaei N, Yadollahi A, Bian L, Thompson SM (2015) An overview of direct laser deposition for additive manufacturing; part II: mechanical behavior, process parameter optimization and control. Addit Manuf 8:12–35

Colaço R, Costa L, Guerra R, Vilar R (1996) A simple correlation between the geometry of laser cladding tracks and the process parameters. In: Mazumder J, Conde O, Vilar R, Steen W (eds) Laser processing: surface treatment and film deposition. Kluwer Academic Publishers, Berlin, pp. 421–429

Zhang K, Liu W, Shang X (2007) Research on the processing experiments of laser metal deposition shaping. Opt Laser Technol 39:549–557

Angelastro A, Campanelli SL, Casalino G, Ludovico AD (2013) Optimization of Ni-based WC/Co/Cr composite coatings produced by multilayer laser cladding. Adv Mater Sci Eng

El Cheikh H, Courant B, Branchu S, Hascoët J-Y, Guillén R (2012) Analysis and prediction of single laser tracks geometrical characteristics in coaxial laser cladding process. Opt Lasers Eng 50:413–422

Hofman JT, De Lange DF, Pathiraj B, Meijer J (2011) FEM modeling and experimental verification for dilution control in laser cladding. J Mater Process Technol 211:187–196

Steen WM (2010) Laser material processing, 4th edn. Springer Verlag, London

Schneider MF (1998) Laser cladding with powder: effect of some machining parameters on clad properties, University of Twente, Ph.D Thesis. Enschede, The Netherlands: Print Partners Ipskamp

Simchi A (2006) Direct laser sintering of metal powders: mechanism, kinetics and microstructural features. Mater Sci Eng A 428:148–158

Yadollahi A, Shamsaei N, Thompson SM, Seely DW (2015) Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mat Sci Eng A-Struct 644:171–183

Cabeza M, Castro G, Merino P, Pena G, Román M (2012) Laser surface melting: a suitable technique to repair damaged surfaces made in 14 Ni (200 grade) marage steel. Surf Coat Technol 212:159–168

Amine T, Newkirk JW, Liou F (2014) Investigation of effect of process parameters on multilayer builds by direct metal deposition. Appl Therm Eng 73:498–509

Casalino G, Campanelli SL, Contuzzi N, Ludovico AD (2015) Experimental investigation and statistical optimisation of the selective laser melting process of a marage steel. Opt Laser Technol 65:151–158

Choi J, Chang Y (2005) Characteristics of laser aided direct metal/material deposition process for tool steel. Int J Mach Tools Manuf 45:597–607

M.V.L. Ramesh, P. Srinivasa Rao, V. Venkateswara Rao. Structure–properties evaluation of dissimilar laser beam welds: marage steel and high strength low alloy steel. Journal of Material Science and Mechanical Engineering (JMSME), 2, 8; April–June, 2015, 42–45.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Campanelli, S.L., Angelastro, A., Signorile, C.G. et al. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterisation. Int J Adv Manuf Technol 89, 885–895 (2017). https://doi.org/10.1007/s00170-016-9135-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9135-x