Abstract

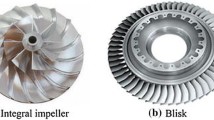

Shrouded blisk components are one of the core parts in aerospace engines. Five-axis or six-axis electrical discharge machining is once regarded as the best solution to manufacturing these components. The machining process, however, is time consuming and money cost. In this paper, an electron beam melting (EBM) and electrical discharge machining (EDM) combined method for shrouded blisks manufacturing was presented. In the new method, EBM was used to generate the near-net forming blank of the shroud blisk, and EDM was responsible for finish machining. The mechanical properties of the EBM formed Ti6Al4V blank was tested to be good enough for shrouded blisks. A visual identification method was proposed to establish the machining reference on the EBM formed blisk blank for the subsequent EDM process. The given example showed the required blade accuracy of ±0.03 mm can be achieved by the visual identification method. Through the combination of EBM and EDM method, the machining time of the shrouded blisk was greatly reduced by 54.8 %.

Similar content being viewed by others

References

Bußmann M, Kraus J, Bayer E (2005) In: Proceedings of 17th symposium on air breathing engines

Bußmann M, Bayer E (2007) In: The First European Air and Space Conference (CEAS 2007)

Liu X, Kang X, Xi X, Liang W, Zhao W (2013) Int J Adv Manuf Technol 68(5-8):1697

Klocke F, Zeis M, Klink A, Veselovac D (2013) CIRP J Manuf Sci Technol 6(3):198

Chen KH (2011) Int J Adv Manuf Technol 52(1–4):235

Ren J, Yao C, Zhang D, Xue Y, Liang Y (2009) Int J Adv Manuf Technol 45(1):101

Xu Z, Xu Q, Zhu D, Gong T (2013) CIRP Ann Manuf Technol 62(1):187

Xu Z, Sun L, Hu Y, Zhang J (2014) Int J Adv Manuf Technol 71(1–4):459

Liu X, Kang X, Zhao W, Liang W (2013) Procedia CIRP 6:107

Yang D, Cao F, Liu J, Yang L, Zhang K, Zhu Y (2013) Procedia CIRP 6:192

Williams CB, Cochran JK, Rosen DW (2011) Int J Adv Manuf Technol 53(1–4):231

Atzeni E, Salmi A (2012) Int J Adv Manuf Technol 62(9–12):1147

Wong KV, Hernandez A (2012) ISRN Mech Eng 2012

Campbell I, Bourell D, Gibson I (2012) Rapid Prototyp J 18(4):255

Murr LE, Gaytan SM, Ramirez DA, Martinez E, Hernandez J, Amato KN, Shindo PW, Medina FR, Wicker RB (2012) J Mater Sci Technol 28(1):1

Gong X, Anderson T, Chou K (2014) Manuf Rev 1:2

Ruan J, Sparks TE, Fan Z, Stroble JK, Panackal A, Liou F (2006) In: Proceedings of the Solid Freeform Fabrication Symposium, pp 233–245

Facchini L, Magalini E, Robotti P, Molinari A (2009) Rapid Prototyp J 15(3):171

Murr LE, Gaytan S, Ceylan A, Martinez E, Martinez J, Hernandez D, Machado B, Ramirez D, Medina F, Collins S et al (2010) Acta Mater 58(5):1887

Hrabe N, Quinn T (2013) Mater Sci Eng A 573:271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, W., Kang, X., Zhao, W. et al. Electrical discharge machining of electron beam melting formed shrouded blisk. Int J Adv Manuf Technol 87, 2319–2326 (2016). https://doi.org/10.1007/s00170-016-8545-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8545-0