Abstract

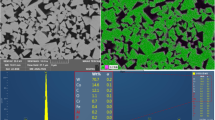

This paper addresses the cutting mechanisms of cemented carbide using a diamond-coated carbide end mill at ultrasmall feed rates. The tool wear behavior, cutting force, and form and surface integrity of the machined groove were experimentally investigated. In addition, the cutting edge temperature, finished surface, and influence of feed rate on tool durability were investigated to determine the cutting characteristics. A large flaking of the coating film on the rake face occurred immediately after the cutting onset, and a sharp cutting edge evolved on the ridgeline of the section of the coating film that remained on the flank face. The cutting force decreased, and the removal volume increased because of the flaking of the coating film on the rake face, which resulted in the evolution of the sharp cutting edge. The temperature of the cutting edge increased with increasing the tool’s speed of revolution, similar to the case of hardened die steel materials, and reached 440–560 °C. No damaged layer was observed on the finished surface layer, as confirmed by compositional mapping of a section of the preliminary and finished surfaces. The durability of the cutting tool deteriorated significantly at feed rates higher than the cross-sectional thickness of the coating film. High wear resistance and cutting performance can be achieved by setting the feed rate to ultrasmall values, less than the thickness of the coating film.

Similar content being viewed by others

References

Takada M, Matsubara H, Kawagishi Y (2013) Wear of cemented carbide dies for steel cord wire drawing. Mater Trans 54:2011–2017

Lu R, Minarro L, Su YY, Shemenski RM (2008) Failure mechanism of cemented tungsten carbide dies in wet drawing process of steel cord filament. Int J Refract Met Hard Mater 26:589–600. doi:10.1016/j.ijrmhm.2008.01.009

Xu MG, Zhang JH, Li Y, Zhang QH, Ren SF (2009) Material removal mechanisms of cemented carbides machined by ultrasonic vibration assisted EDM in gas medium. J Mater Process Technol 209:1742–1746. doi:10.1016/j.jmatprotec.2008.04.031

Singh H, Shukla DK (2012) Optimizing electric discharge machining parameters for tungsten-carbide utilizing thermo-mathematical modelling. Int J Therm Sci 59:161–175. doi:10.1016/j.ijthermalsci.2012.03.017

Jahan MP, Wong YS, Rahman M (2009) A study on the quality micro-hole machining of tungsten carbide by micro-EDM process using transistor and RC-type pulse generator. J Mater Process Technol 209:1706–1716. doi:10.1016/j.jmatprotec.2008.04.029

Jahan MP, Wong YS, Rahman M (2009) A study on the fine-finish die-sinking micro-EDM of tungsten carbide using different electrode materials. J Mater Process Technol 209:3956–3967. doi:10.1016/j.jmatprotec.2008.09.015

Lee SH, Li X (2003) Study of the surface integrity of the machined workpiece in the EDM of tungsten carbide. J Mater Process Technol 139:315–321. doi:10.1016/S0924-0136(03)00547-8

Abdullar A, Mohammad RS, Ivanov A, Mohammad T, Tabar S (2009) Effect of ultrasonic-assisted EDM on the surface integrity of cemented tungsten carbide (WC-Co). Int J Adv Manuf Technol 41:268–280. doi:10.1007/s00170-008-1476-7

Huang SH, Huang FY, Yan BH (2005) Fracture strength analysis of micro WC-shaft manufactured by micro-electro-discharge machining. Int J Adv Manuf Technol 26:68–77. doi:10.1007/s00170-003-1974-6

Yang J, Odén M, Johansson-Jõesaar MP, Llanes L (2014) Grinding effects on surface integrity and mechanical strength of WC-Co cemented carbides. Procedia CIRP 13:257–263. doi:10.1016/j.procir.2014.04.044

Yin L, Spowage AC, Ramesh K, Huang H, Pickering JP, Vancoille EYJ (2004) Influence of microstructure on ultraprecision grinding of cemented carbides. Int J Mach Tools Manuf 44:533–543. doi:10.1016/j.ijmachtools.2003.10.022

Luo SY, Liu YC, Chou CC, Chen TC (2001) Performance of powder filled resin-bonded diamond wheels in the vertical dry grinding of tungsten carbide. J Mater Process Technol 118:329–336. doi:10.1016/S0924-0136(01)00861-5

Uehara Y, Ohmori H, Yamagata Y et al. (2002) Grinding characteristics of cemented carbide concave mirror by desk-top type 4-axes machine “TRIDER-X” with ELID system. Initiat Precis Eng Beginning Millenn 476–480. doi: 10.1007/0-306-47000-4_93

Singh GK, Yadava V, Kumar R (2010) Diamond face grinding of WC-Co composite with spark assistance: experimental study and parameter optimization. Int J Precis Eng Manuf 11:509–518. doi:10.1007/s12541-010-0059-3

Abdullah A, Pak A, Farahi M, Barzegari M (2007) Profile wear of resin-bonded nickel-coated diamond wheel and roughness in creep-feed grinding of cemented tungsten carbide. J Mater Process Technol 183:165–168. doi:10.1016/j.jmatprotec.2006.09.038

Zhang L, Zhao YW, He XS, Kuriyagawa T (2008) An investigation of effective area in electrorheological fluid-assisted polishing of tungsten carbide. Int J Mach Tools Manuf 48:295–306. doi:10.1016/j.ijmachtools.2007.10.011

Okada A, Kitada R, Okamoto Y, Uno Y (2011) Surface modification of cemented carbide by EB polishing. CIRP Ann 60:575–578. doi:10.1016/j.cirp.2011.03.107

Beaucamp A, Namba Y, Messelink W, Walker D, Charlton P, Freeman R (2014) Surface integrity of fluid jet polished tungsten carbide. Proc CIRP 13:377–381. doi:10.1016/j.procir.2014.04.064

Bulla B, Klocke F, Dambon O (2012) Analysis on ductile mode processing of binderless, nano crystalline tungsten carbide through ultra precision diamond turning. J Mater Process Technol 212:1022–1029. doi:10.1016/j.jmatprotec.2011.12.010

Harano K, Satoh T, Sumiya H (2012) Cutting performance of nano-polycrystalline diamond. Diam Relat Mater 24:78–82. doi:10.1016/j.diamond.2011.11.005

Nath C, Rahman M, Neo KS (2009) Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 49:1089–1095. doi:10.1016/j.ijmachtools.2009.07.006

Liu K, Li XP, Rahman M, Liu XD (2003) CBN tool wear in ductile cutting of tungsten carbide. Wear 255:1344–1351. doi:10.1016/S0043-1648(03)00061-9

Goel S, Luo X, Agrawal A, Reuben RL (2015) Diamond machining of silicon: a review of advances in molecular dynamics simulation. Int J Mach Tools Manuf 88:131–164. doi:10.1016/j.ijmachtools.2014.09.013

Okada M, Hosokawa A, Tanaka R, Ueda T (2011) Cutting performance of PVD-coated carbide and CBN tools in hardmilling. Int J Mach Tools Manuf 51:127–132. doi:10.1016/j.ijmachtools.2010.10.007

Okada M, Asakawa N, Sentoku E, M’Saoubi R, Ueda T (2014) Cutting performance of an indexable insert drill for difficult-to-cut materials under supplied oil mist. Int J Adv Manuf Technol 72:475–485. doi:10.1007/s00170-014-5691-0

Ueda T, Sato M, Hosokawa A, Ozawa M (2008) Development of infrared radiation pyrometer with optical fibers—two-color pyrometer with non-contact fiber coupler. CIRP Ann 57:69–72. doi:10.1016/j.cirp.2008.03.056

Ueda T, Sato M, Sugita T, Nakayama K (1995) Thermal behavior of cutting grain in grinding. CIRP Ann 44:325–328. doi:10.1016/S0007-8506(07)62335-X

Furumoto T, Ueda T, Kasai A, Hosokawa A (2011) Surface temperature during cavity preparation on human tooth by Er:YAG laser irradiation. CIRP Ann 60:555–558. doi:10.1016/j.cirp.2011.03.065

Ueda T, Hosokawa A, Oda K, Yamada K (2001) Temperature on flank face of cutting tool in high speed milling. CIRP Ann 50:37–40. doi:10.1016/S0007-8506(07)62065-4

Minton T, Ghani S, Sammler F, Bateman R, Fürstmann P, Roeder M (2013) Temperature of internally-cooled diamond-coated tools for dry-cutting titanium. Int J Mach Tools Manuf 75:27–35. doi:10.1016/j.ijmachtools.2013.08.006

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okada, M., Yoshida, A., Furumoto, T. et al. Mechanisms and characteristics of direct cutting of tungsten carbide using a diamond-coated carbide end mill. Int J Adv Manuf Technol 86, 1827–1839 (2016). https://doi.org/10.1007/s00170-015-8324-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8324-3