Abstract

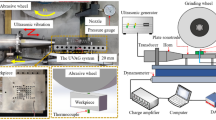

Understanding the chip formation is one of most important issues in controlling the grinding wheel performance or the work surface finish in grinding process. This article discusses the effects of the ultrasonic vibration and peripheral speed of grinding wheel on the chip size and geometry in ultrasonic assisted grinding (UAG) of Inconel 718 with an electroplated cBN grinding wheel. Firstly, scanning electron microscopic (SEM) observations were performed on the chips formed at different vibration amplitudes and wheel peripheral speeds. The obtained 3D SEM images were used to determine the length and cross-section area of chips. Then, the geometries of chips were observed with SEM. The obtained results demonstrated that (1) chip size and geometry were distinctly affected by the ultrasonic vibration of grinding wheel but hardly by the wheel peripheral speed, e.g., the cross-section area of chips became smaller by 64.3 % and the length decreased by 36.3 %, respectively, once the ultrasonic vibration with an amplitude of A p-p = 9.4 μm has been imposed to the grinding wheel; (2) the UAG is potentially avoiding the formation of shear chips and prefers the flow chips, especially at larger amplitude; (3) little changes were found on the chip geometry as the wheel peripheral speed increased in UAG; (4) the change in the chip size and geometry caused by the ultrasonic vibration was supposed to be owing to the ultrasonic lubrication and the vibration in the rake angle of grain cutting edge.

Similar content being viewed by others

References

Sharman A, Dewes RC, Aspinwall DK (2001) Tool life when high speed ball nose end milling Inconel 718. J Mater Process Technol 118:29–35. doi:10.1016/S0924-0136(01)00855-X

Radhakrishna CH, Prasad Rao K (1997) The formation and control of laves phase in superalloy 718 welds. J Mater Sci 32:1977–1984. doi:10.1023/A:1018541915113

Ezugwu EO, Fadare DA, Bonney J, Da Silva RB, Sales WF (2005) Modelling the correlation between cutting and process parameters in high-speed machining of inconel 718 alloy using an artificial neural network. Int J Mach Tools Manuf 45:1375–1385. doi:10.1016/j.ijmachtools.2005.02.004

Arunachalam M, Mannan MA, Spowage AC (2004) Surface integrity when machining age hardened inconel 718 with coated carbide cutting tools. Int J Mach Tools Manuf 44:1481–1491. doi:10.1016/j.ijmachtools.2004.05.005

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51:250–280. doi:10.1016/j.ijmachtools.2010.11.003

Khidhir BA, Mohamed B (2010) Machining of nickel based alloys using different cemented carbide tools. J Eng Sci Technol 5(3):264–271

Arunachalam RM, Mannan MA, Spowage AC (2004) Residual stress and surface roughness when facing age hardened Inconel 718 with CBN and ceramic cutting tools. Int J Mach Tools Manuf 44:879–887. doi:10.1016/j.ijmachtools.2004.02.016

Ozcelik B, Oktem H, Kurtaran H (2005) Optimum surface roughness in end milling inconel 718 by coupling neural network model and genetic algorithm. Int J Adv Manuf Technol 27:234–241. doi:10.1007/s00170-004-2175-7

Kitagawa T, Kubo A, Maekawa K (1997) Temperature and wear of cutting tools in high-speed machining of inconel 718 and Ti-6Al-6V-2Sn. Wear 202:142–148. doi:10.1016/S0043-1648(96)07255-9

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to- machine materials with regard to cutting fluids. Int J Mach Tools Manuf 57:83–101. doi:10.1016/j.ijmachtools.2012.02.002

Santosh Ranganath, Changsheng Guo, Sean Holt (2009) Experimental Investigations Into the Carbide Cracking Phenomenon on Inconel 718 Superalloy Material, ASME 2009 International Manufacturing Science and Engineering Conference Volume 2:33–39. doi:10.1115/MSEC2009-84085

Zemzemi F, Rech J, Ben Salem W, Dogui A, Kapsa P (2014) Identification of friction and heat partition model at the tool-chip-workpiece interfaces in dry cutting of an Inconel 718 alloy with CBN and coated carbide tools. Adv Manuf Sci Technol 38(1):5–22. doi:10.2478/amst-2014-0001

Ohkubo C, Toshio H, Phillip Ford J, Watanabe I (2006) Effect of surface reaction layer on grindability of cast titanium alloys. Dent Mater 22(3):268–274. doi:10.1016/j.dental.2005.04.020

Irani RA, Bauer RJ, Warkentin A (2005) A review of cutting fluid application in the grinding process. Int J Mach Tools Manuf 45:1696–1705. doi:10.1016/j.ijmachtools.2005.03.006

Liu JH, Pei ZJ, Fisher GR (2007) Grinding wheels for manufacturing of silicon wafers: a literature review. Int J Mach Tools Manuf 47:1–13. doi:10.1016/j.ijmachtools.2006.02.003

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32:153–172. doi:10.1016/j.precisioneng.2007.08.003

Pei Z, Ferreira P (1998) Modeling of ductile-mode material removal in rotary ultrasonic machining, Int. J Mach Tools Manuf 38:1399–1418. doi:10.1016/S0890-6955(98)00007-8

Jianguo C, Yongbo W, Dong L, Masakazu F, Mitsuyoshi N (2014) Material removal behavior in ultrasonic-assisted scratching of SiC ceramics with a single diamond tool. Int J Mach Tools Manuf 79:49–61. doi:10.1016/j.ijmachtools.2014.02.002

Bhaduri D, Soo SL, Aspinwal DK (2012) A study on ultrasonic assisted creep feed grinding of nickel based superalloys. Procedia CIRP 1:359–364. doi:10.1016/j.procir.2012.04.064

Bhaduri D, Soo SL, Novovic D, Aspinwall DK, Harden P, Waterhouse C (2013) Ultrasonic assisted creep feed grinding of inconel 718. Procedia CIRP 6:616–621. doi:10.1016/j.procir.2013.03.044

Zahedi A, Tawakoli T, Akbari J (2015) Energy aspects and workpiece surface characteristics in ultrasonic assisted cylindrical grinding of alumina-zirconia ceramics. Int J Mach Tools Manuf 90:16–28. doi:10.1016/j.ijmachtools.2014.12.002

Tso P-L, Wu S-H (1990) Analysis of grinding quantities through chip sizes. J Mater Process Technol 95:1–17. doi:10.1016/S0924-0136(99)00297-6

Lu L, Farris TN, Chandrasekar S (1992) Paper VI (iv) sliding microindentation wear particles: spheres in grinding swarf. Tribology Series 21:257–263. doi:10.1016/S0167-8922(08)70531-5

Jianbo D, Wenfeng D, Liangchi Z, Jiuhua X, Honghua S (2015) Understanding the effects of grinding speed and undeformed chip thickness on the chip formation in high-speed grinding. Int J Adv Manuf Technol 81(5):995–1005. doi:10.1007/s00170-015-7265-1

Milton C. Shaw (1996) Principles of abrasive processing, Mech. Chem. Engng., Inst. Engrs, Australia MC8, 73

Salje E, Mohlgan H (1986) Fundamental dependencies upon contact lengths and results in grinding. CIRP Ann Manuf Technol 35(1):249–253. doi:10.1016/S0007-8506(07)61881-2

Ioan D. Marinescu Mike P. Hitchiner, Eckart Uhlmann W. Brian Rowe Ichiro Inasak (2006) Handbook of Machining with Grinding Wheels, CRC Press, Technology & Engineering:632 ISBN: 978-1-57444-671-5

Taghi T, Bahman A, Mohammad R (2009) Ultrasonic assisted dry grinding of 42CrMo4. Int J Adv Manuf Technol 42:883–891. doi:10.1007/s00170-008-1646-7

Tso P-L (1995) An investigation of chip types in grinding. J Mater Process Technol 53:521–532. doi:10.1016/0924-0136(94)01746-N

Wu YB, Nomura M, Feng ZJ, Kato M (2004) Modeling of grinding force in constant-depth-of-cut ultrasonically assisted grinding. Mater Sci Forum 471–472:101–106. doi:10.4028/www.scientific.net/MSF.471-472.101

Teidelt E, Starcevic J, Popov VL (2012) Influence of ultrasonic oscillation on static and sliding friction. Tribol Lerr 48:51–62. doi:10.1007/s11249-012-9937-4

Park CH, Inman DJ (2003) Enhanced piezoelectric shunt design. Shock Vib 10(2):127–133. doi:10.1155/2003/863252

Aslan D, Budak E (2015) Surface roughness and thermo-mechanical force modeling for grinding operations with regular and circumferentially grooved wheel. Int J Mach Tools Manuf 223:75–90. doi:10.1016/j.jmatprotec.2015.03.023

Liang Z, Wu Y, Wang X, Zhao W (2010) A new two-dimensional ultrasonic assisted grinding (2D-UAG) method and its fundamental performance in monocrystal silicon machining. Int J Mach Tools Manuf 5(8):728–736. doi:10.1016/j.ijmachtools.2010.04.005

Griffith B (2001) Manufacturing, surface technology-surface integrity and functional performance. Penton Press, London

Armarego EJ, Brown RH (1969) The machining of metals. Prentice-Hall, Englewood Cliffs, New Jersey

Park HW (2008) Development of micro-grinding mechanics and machine tools. Georgia Institute of Technology, United States

Zhang DK, Li C, Jia D, Zhang Y (2014) Investigation into engineering ceramics grinding mechanism and the influential factors of the grinding force. Int J Control Autom 7(4):19–34. doi:10.14257/ijca.2014.7.4.03

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, S., Wu, Y. & Nomura, M. Effect of grinding wheel ultrasonic vibration on chip formation in surface grinding of Inconel 718. Int J Adv Manuf Technol 86, 1113–1125 (2016). https://doi.org/10.1007/s00170-015-8149-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8149-0