Abstract

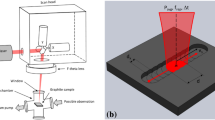

Fine polished and 4 N (99.99 %) pure gold is irradiated using Nd:YAG laser (1064 nm, 50 mJ, 10 Hz). Drilling is performed in air by increasing number of laser shots on the target surface. After each set of shots, the surface morphology and crater dimensions have been taken into account. SEM JEOL (JSM-7500F) and optical microscope (STM6-LM OLYMPUS Corporation) are used as characterization tools. It is revealed from SEM micrographs that heat conduction is non-uniform and more in the upward direction. Ripples, cones, and cone-like topography are observed. Droplets of micron size and nanoparticles have also been formed at 3000 number of laser shots where perforation occurs. Combining the investigations of SEM and optical microscope, it is observed that with the increase in laser shots, the crater width along horizontal increases and then decreases. It follows the Gaussian trend of variation. Crater width along vertical also increases and then decreases showing Gaussian trend of variation. Crater depth increases by increasing number of laser shots till perforation occur, chasing a linear growth. Heat-affected zone (HAZ) expands, exhibiting the Gaussian way of expansion with increase in laser shots.

Similar content being viewed by others

References

Mishra S, Yadava V (2015) Laser beam micromachining. Opt Lasers Eng 73:1–150

Lenzner M (1998) Femtosecond optical breakdown in dielectrics. Phys Rev Lett 80:4076–4079

Bauerle D (2000) Laser processing and chemistry. Springer, Berlin

Yilbas BS, Shuja SZ (1999) Laser short-pulse heating of surfaces. Appl Phys 32:1947–1954

Harrington RE (1967) Application of the theory of heat conduction to the absorption of blackbody radiation. Appl Phys 38:3266–3327

Fujimoto JG, Liu JM, Ippen EP (1984) Femto laser interaction with metallic tungsten and non equilibrium electron and lattice temperatures. Phys Rev Lett 53:1837–1840

Elsayed-Ali HE, Norri TB, Pessot MA, Mourou GA (1987) Time-resolved observation of electron-phonon relaxation in copper. Phys Rev Lett 58:1212–1215

Bulgakova NM, Stoian R, Rosenfeld A, Hertel IV, Marine W, Campbell EEB (2005) A general continuum approach to describe fast electronic transport in pulsed laser irradiated materials: the problem of Coulomb explosion. Appl Phys A 81:345–356

Martin J, Cibulka O, Semmar N (2006) Nanosecond pulse laser melting investigation by IR radiometry and reflection-based methods. Appl Surf Sci 253:1170–1177

Bagghi S, Kiran PPS, Bhuyan MK, Bose S et al. (2008) Laser and particle beams 26: 259–264.

Sundram SK, Mazur E (2002) Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses. Nat Mater 1:767

Tian Y, Wu BX, Shin YC (2008) Laser-assisted milling of silicon nitride and Inconel 718. Trans ASME J Manuf Sci Eng 130:031013

Gower MC (1996) Industrial applications of laser micromachining. Opt Express 7:56–67

Klossika JJ, Gratzke U, Vicanek M, Simon G (1996) Importance of a finite speed of heat propagation in metals irradiated by femtosecond laser pulses. Phys Rev B 54:10227–10279

Miller JC, Hugland RF (1998) Laser ablation and desorption, vol 30. New York, Academic Press

Allen PB (1987) Theory of thermal relaxation of electrons in metals. Phys Rev 59:1460–1463

Latif A, Rahman MK, Rafique MS (2005) Conference on advanced materials, 6–8, Putrajaya, Malaysia

Yilbas BS, Arif AFM (2000) Material response to thermal loading due to short pulse laser heating. Int J Heat Mass Transfer 44:3787–3798

Wang X, Zhang Y, Liu S, Zhao Z (2014) Depth profiling by Raman spectroscopy of high-energy ion irradiated silicon carbide. Nucl Instrum Methods Phys Res B 319:55–61

Wang XY, Riffe DM, Lee YS, Downer MC (1994) Time-resolved electron-temperature measurement in a highly excited gold target using femtosecond thermionic emission. Phys Rev B50:8016–8019

Latif A (2011) The diagnostic and analysis of optical, thermal and electrical properties of laser ablated materials. Department of Physics, University of Engineering and Technology, Lahore

Latif A, Khaleeq-ur-Rahman M, Bhatti KA, Rafique MS, Rizvi ZH (2010) Crystallography and surface morphology of ion-irradiated silver. Radiat Eff Defects Solids 166:1–7

Zuhlke CA, Anderson TP, Alexander DR (2013) Formation of multiscale surface structures on nickel via above surface growth and below surface growth mechanisms using femtosecond laser pulses. Opt Express 21:8460–8473

Demir AG, Furlan V, Lecis N, Previtali B (2014) Laser surface structuring of AZ31 Mg alloy for controlled wettability. Biointerphases 9:029009

Zuhlke CA, Anderson TP, Alexander DR (2013) Fundamentals of layered nanoparticle covered pyramidal structures formed on nickel during femtosecond laser surface interactions. Appl Surf Sci 283:648–653

Tanvir Ahmmed KM, Yang Ling EJ, Servio P, Kietzig AM (2015) Introducing a new optimization tool for femtosecond laser-induced surface texturing on titanium, stainless steel, aluminum and copper. Opt Lasers Eng 66:258–268

Farnia A, MalekGhaini F, Ocelik V, Hoson JTM (2013) Microstructural characterization of Co-based coating deposited by low power pulse laser cladding. J Mater Sci 48:2714–2723

Sahoo CK, Masanta M (2015) Effect of pulse laser parameters on TiC reinforced AISI 304 stainless steel composite coating by laser surface engineering process. Opt Lasers Eng 67:36–48

Honda M, Saito Y, Smith NI, Fujita K, Kawata S (2014) Nanoscale heating of laser irradiated single gold nanoparticles in liquid. Opt Express 19:376–384

Benavides O, May LC, Gil AF, Jimenez JA L (2015) Experimental study on reflection of high-intensity nanosecond Nd:YAG laser pulses in ablation of metals. Opt Lasers Eng 68:83–86

Xu S, Qiu J, Jia T, Li C, Sun H, Xu Z (2007) Femtosecond laser ablation of crystals SiO2 and YAG. Opt Commun 274:163–166. doi:10.1016/j.optcom

Du D, Liu X, Mourou G (1996) Reduction of multi-photon ionization in dielectrics due to collisions. Appl Phys B 63:617–621

Kelly R, Rothenberg JE (1985) Laser sputtering Part III. The mechanism of the sputtering of metals low energy densities. Nucl Instrum Methods Phys Res B7/8:755–763

Chung SH, Mazur E (2009) Surgical applications of femtosecond lasers. Journal of Biophotonics 2(10):557–572

Manika I, Maniks J, Schwartz K, Trautmann C (2002) Hardening and formation of dislocation structures in LiF crystals irradiated with MeV–GeV ions. Nucl Instrum Methods Phys Res B 196:299–307

Hashimoto N, Hunn JD, Byun TS, Mansur LK (2003) Microstructural analysis of ion-irradiation-induced hardening in Inconel 718. J Nucl Mater 318:300–306

Chrisey DB, Hubbler GK (1994) Pulsed laser deposition of thin films. Wiley, USA

Rafique MS, Khaleeq ur Rehman M, Siraj K, Shahid S, Mehmood F, Anwar MS, Ashfaq A (2004) Forward peaking of laser produced plasma plume, proceeding of 31st European Physical Society Conference on Plasma Physics, vol 28B, London Imperial College, London, p 5–048

Jordan R, Cole D, Lunney JG, Machay K, Givord D (1995) Pulsed laser ablation of copper. Appl Surface Sci 86:24–28

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Latif, A., Rafiq, M.S., Bhatti, K.A. et al. Crater geometry and morphological changes on gold sheet during laser microdrilling. Int J Adv Manuf Technol 85, 2847–2855 (2016). https://doi.org/10.1007/s00170-015-8103-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8103-1