Abstract

Additive manufacturing (AM) is a promising technology for many industrial sectors, from aerospace to personal care goods. However, when it comes to high-quality components, CNC machining is still the most reliable solution. A lot of research has been conducted for modeling and predicting the quality of an additive manufactured or machined part. However, the state of the art clearly indicates that the short-term future of manufacturing will be mostly comprised of process chains, which combine both subtractive and additive manufacturing processes. Taking this into account, this paper presents a modeling methodology for a process chain consisting of laser cladding, as an AM process, and high speed machining (HSM), a subtractive process usually used for finishing operations. The modeling methodology, which is based on the finite element method and utilizes the level set method to define the cutting tool path, is able to predict results such as residual stresses and part distortion. The proposed approach is applied in simulating HSM of a steel tube fabricated by laser cladding. The results are showing that machining can partially eliminate the residual stresses and distortion caused by laser cladding.

Similar content being viewed by others

References

Chen D, Heyer S, Ibbotson S, Salonitis K, Steingrímsson GJ, Thiede S (2015) Direct digital manufacturing: definition, evolution, and sustainability implications. J Clean Prod 107:615–625

Pandey PM, Venkata Reddy N, Dhande SG (2003) Improvement of surface finish by staircase machining in fused deposition modeling. J Mater Process Technol 132(1-3):323–331

Roland Berger Strategy Consultants. (2013) Additive manufacturing - A game changer for the manufacturing industry? Munich:. Available from: http://www.rolandberger.com/media/pdf/Roland_Berger_Additive_Manufacturing_20131129.pdf

Schoinochoritis B, Chantzis D, Salonitis K. (2015) Simulation of metallic powder bed additive manufacturing processes with the finite element method: a critical review. Proc IMechE Part B: J Eng Manuf, published online,1–22 doi: 10.1177/0954405414567522)

Mercelis P, Kruth J (2006) Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp J 12(5):254–265

Hornbach D, Prevéy P. (1998) Development of machining procedures to minimize distortion during manufacture. In 17th Heat Treating Society Conference and Exposition.

Yang Y, Li M, Li KR (2014) Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int J Adv Manuf Technol 70(9-12):1803–1811

Jayanti S, Ren D, Erickson E, Usui S, Marusich T, Marusich K et al (2013) Predictive modeling for tool deflection and part distortion of large machined components. Procedia CIRP 12:37–42

Marusich TD, Askari E. (2001) Modeling residual stress and workpiece quality in machined surfaces. In 4th CIRP International Workshop Modeling of machining operation; Delft.

Afazov SM (2013) Modelling and simulation of manufacturing process chains. CIRP J Manuf Sci Technol 6(1):70–77

Dattoma V, De Giorgi M, Nobile R (2006) On the evolution of welding residual stress after milling and cutting machining. Comput Struct 84(29-30):1965–1976

Rossini NS, Dassisti M, Benyounis KY, Olabi AG (2012) Methods of measuring residual stresses in components. Mater Des 35:572–588

Picasso M, Marsden CF, Wagniere JD, Frenk A, Rappaz M (1994) A simple but realistic model for laser cladding. Metall Mater Trans B 25:281–291

Yevko V, Park CB, Zak G, TW. C, Benhabib B (1998) Cladding formation in laser-beam fusion of metal power. Rapid Prototyp J 4:68–184

Toyserkani E, Khajepour A, Corbin S (2003) Three-dimensional finite element modeling of laser cladding by powder injection: effects of powder feedrate and travel speed on the process. J Laser Appl 15:153–160

Toyserkani E, Khajepour A, Corbin S (2004) 3-D finite element modeling of laser cladding by powder injection: effects of laser pulse shaping on the process. Opt Lasers Eng 41:849–869

Lalas C, Tsirbas K, Salonitis K, Chryssolouris G (2007) An analytical model of the laser clad geometry. Int J Adv Manuf Technol 32:34–41

Salonitis K, Stavropoulos P, Stournaras A, Chryssolouris G. (2007) Thermal modelling of the laser cladding process. In Proceedings of the 5th LANE. 825-835

Lin J (1999) A simple model of powder catchment in coaxial laser cladding. Opt Laser Technol 31:223–238

Gedda H, Powell J, Wahlstrom G, Li W-B, Engstrom H, Magnusson C (2002) Energy redistribution during CO2 laser cladding. J Laser Appl 14:78–82

Gedda H, Powell J, Kaplan A. (2002) A process efficiency comparison of Nd:YAG and CO2 laser cladding. Proceedings of ICALEO’ 02.

D’Alvise L, Chantzis D, Schoinochoritis B, Salonitis K (2015) Modelling of part distortion due to residual stresses relaxation: an aeronautical case study. Procedia CIRP 31:447–452

Movahhedy M, Gadala MS, Altintas Y (2000) Simulation of the orthogonal metal cutting process using an arbitrary Lagrangian–Eulerian finite-element method. J Mater Process Technol 103(2):267–275

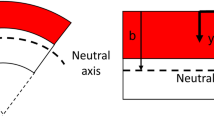

Pierard O, Barboza J, Duflot M, D’Alvise L. (2008) Relaxation of residual stresses during multi-pass machining: simulation with the level-set method and process optimization. In Proceedings of the 8th World Congress on Computational Mechanics (WCCM8) and 5th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2008); Venice, Italy.

Osher S, Sethian JA (1988) Fronts propagating with curvature dependent speed: algorithms based on hamilton-jacobi formulations. J Comput Phys 79:12–49

Zhang Z, Li L, Yang Y, He N, Zhao W (2014) Machining distortion minimization for the manufacturing of aeronautical structure. Int J Adv Manuf Technol 73(9-12):1765–1773

Hamdan A, Sarhan AD, Hamdi M (2012) An optimization method of the machining parameters in high-speed machining of stainless steel using coated carbide tool for best surface finish. Int J Adv Manuf Technol 58(1-4):81–91

Davoodi B, Hosseinzadeh H (2012) A new method for heat measurement during high speed machining. Measurement 45(8):2135–2140

Begic-Hajdarevic D, Cekic A, Kulenovic M (2014) Experimental study on the high speed machining of hardened steel. Procedia Eng 69:291–295

EN 1993-1-2 (2005): Eurocode 3: Design of steel structures—part 1-2: general rules—structural fire design [Authority: The European Union Per Regulation 305/2011, Directive 98/34/EC, Directive 2004/18/EC]

Michaleris P (2014) Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem Anal Des 86:51–60

Heigel JC, Michaleris P, Reutzel EW, Heigel JC, Michaleris P, Reutzel EW (2015) Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Addit Manuf 5:9–19

Suárez A, Amado JM, Tobar MJ, Yáñez A, Fraga E, Peel MJ (2010) Study of residual stresses generated inside laser cladded plates using FEM and diffraction of synchrotron radiation. Surf Coat Technol 204(12–13):1983–1988

Chew Y, Pang JHL, Bi G, Song B (2015) Thermo-mechanical model for simulating laser cladding induced residual stresses with single and multiple clad beads. J Mater Process Technol 224:89–101

Chantzis D, Van-der-Veen S, Zettler J, Sim WM (2013) An industrial workflow to minimize part distortion for machining of large monolithic components in aerospace industry. Procedia CIRP 8:281–286

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salonitis, K., D’Alvise, L., Schoinochoritis, B. et al. Additive manufacturing and post-processing simulation: laser cladding followed by high speed machining. Int J Adv Manuf Technol 85, 2401–2411 (2016). https://doi.org/10.1007/s00170-015-7989-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7989-y