Abstract

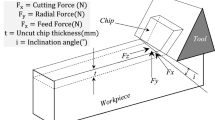

In this paper, the AdvantEdge FEM is used to investigate the performance of microhole textured cutting tools in dry three-dimensional (3D) turning of Ti alloy (Ti-6A1-4V). Microholes are designed on the rake face of cemented carbide (WC/Co) cutting inserts. The purpose is to assess the effect of microhole textured cutting tool on machining performance and to compare it with non-textured regular cutting tools. Specifically, the following microhole parameters are tested: microhole diameter, microhole depth, edge distance (the distance from cutting edge to the first line of microholes), and microhole position pattern. Their effects are assessed in terms of the cutting forces and tool-chip contact length. It is found that microhole textured cutting tools generate lower cutting force and consequently lower-energy consumption for machining. Moreover, the microhole diameter, the microhole depth, the edge distance, and the microhole position pattern all affect the cutting forces of the machining in their own way.

Similar content being viewed by others

References

Lei S, Devarajan S, Chang Z (2009) A study of micropool lubricated cutting tool in machining of mild steel. J Mater Process Technol 209(3):1612–1620

Deng J, Wu Z, Lian Y, Qi T, Cheng J (2012) Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes. Int J Refract Met Hard Mater 30:164–172

Wu Z, Deng J, Chen Y, Xing Y, Zhao J (2012) Performance of the self-lubricating textured tools in dry cutting of Ti-6Al-4V. Int J Adv Manuf Technol 62:943–951

Deng J, Lian Y, Wu Z, Xing Y (2013) Performance of femtosecond laser-textured cutting tools deposited with WS2 solid lubricant coatings. Surf Coat Technol 222:135–143

Xing Y, Deng J, Zhao J, Zhang G, Zhang K (2013) Cutting performance and wear mechanism of nanoscale and microscale textured Al2O3/TiC ceramic tools in dry cutting of hardened steel. Int J Refract Met Hard Mater 43:46–58

Kawasegi N, Sugimori H, Morimoto H, Morita N, Hori I (2009) Development of cutting tools with microscale and nanoscale testures to improve friction behavior. Precision 33:248–254

Da Silva WM, Suarez MP, Machado AR, Costa HL (2013) Effect of laser surface modification on the micro-abrasive wear resistance of coated cemented carbide tools. Wear 302(1–2):1230–1240

Obikawa T, Kamio A, Takaoka H, Osada A (2011) Micro-texture at the coated tool face for high performance cutting. Int J Mach Tools Manuf 51(12):966–972

Chang W, Sun J, Luo X, Ritchie JM, Mack C (2011) Investigation of microstructured milling tool for deferring tool wear. Wear 271(9–10):2433–2437

Sugihara T, Enomoto T (2012) Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis Eng J Int Soc Precis Eng Nanotechnol 36(2):229–237

Enomoto T, Sugihara T, Yukinaga S, Hirose K, Satake U (2012) Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Annals Manuf Technol 61(1):571–574

Xie J, Luo M, He J, Liu X, Tan T (2012) Micro-grinding of micro-groove array on tool rake surfce for dry cutting of titanium alloy. Int J Precis Eng Manuf 13(10):1845–1852

Koshy P, Tovey J (2011) Performance of electrical discharge textured cutting tools. CIRP Annals Manuf Technol 60(1):153–156

Obikawa T, Kani B (2011) Micro ball and milling of titanium alloy using a tool with a microstructured rake face. J Adv Mech Des Syst Manuf 6(7):1121–1131

Chen Z, Zhang J, Feng P, Wu Z (2013) A simulation study on the effect of micro-textured tools during orthogonal cutting of titanium alloy Ti-6Al-4V. Appl Mech Mater 281:389–394

Xing Y, Deng J, Li S, Yue H, Meng R, Gao P (2014) Cutting performance and wear characteristics of Al2O3/TiC ceramic cutting tools with WS2/Zr soft-coatings and nano-textures in dry cutting. Wear 318(1–2):12–16

Xing Y, Deng J, Zhao J, Zhang G, Zhang K (2014) Cutting performance and wear mechanism of nanoscale and microscale textured Al2O3/TiC ceramic tools in dry cutting of hardened steel. Int J Refract Met Hard Mater 43:46–58

Wu Z, Deng J, Su C, Luo C, Xia D (2014) Performance of the micro-texture self-lubricating and pulsating heat pipe self-cooling tools in dry cutting process. Int J Refract Met Hard Mater 45:238–248

Ma J, Duong N, Lei S (2015) Numerical investigation of the performance of microbump textured cutting tool in dry machining of AISI 1045 steel. J Manuf Process. doi:10.1016/j.jmapro.2014.10.001

Ma J, Duong N, Lei S (2015) FEM investigation of friction and wear of microgrooved cutting tool in dry machining of AISI 1045 steel. Proc Inst Mech Eng J J Eng Tribol 229(4):449–464. doi:10.1177/1350650114556395

Kiyota H, Itoigawa F, Nakamura T (2014) Experimental research of micro-textured tool for reduction in cutting force. 17th Conference of the European Scientific Association on Material Forming, ESAFORM 2014; Espoo; Finland; 7 May 2014 through 9 May 2014. 611–612: 1258–1263

Zhang JF, Chen ZM, Feng PF, Xu WH (2013) The characteristics of titanium alloy chip-breaking by orthogonal cutting with a surface-textured cutting tool. 2nd International Conference on Machine Design and Manufacturing Engineering, ICMDME. Jeju Island; South Korea; 1 May 2013 through 2 May 2013

AdvantEdge FEM User’s Manual, Version 6.0, 2013

Mills KC (2002) Recommended values of thermophysical properties for selected commercial alloys. Woodhead, Cambridge

CES EduPack 2011, version 7.0

Ozel T, SIma M, Srivastava AK, Kaftanoglu B (2010) Investigations on the effects of multi-layered coated inserts in machining Ti-6Al-4V alloy with experiments and finite lement simulations. CIRP Ann Manuf Technol 59:77–82

Wu Z, Deng J, Chen Y, Xing Y, Zhao J (2012) Performance of the self-lubricating textured tools in dry cutting of Ti-6Al-4V. Int J Adv Manuf Tech 62:943–951

Zhang Y, Mabrouki T, Nelias D, Gong Y (2010) FE-model for titanium alloy (Ti-6Al-4V) cutting based on the identification of limiting shear stress at tool-chip interface. Int J Mater Form 4:11–23

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, J., Ge, X., Qiu, C. et al. FEM assessment of performance of microhole textured cutting tool in dry machining of Ti-6Al-4V. Int J Adv Manuf Technol 84, 2609–2621 (2016). https://doi.org/10.1007/s00170-015-7918-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7918-0