Abstract

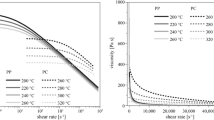

In the work reported, μ-IM and μ-ICM using replaceable silicon mould inserts were utilized for prototyping test structures with micrometric and sub-micrometric feature size in thermoplastic polymers (polypropylene and cyclic olefin copolymer). The mould inserts were manufactured using clean room technologies. The combination of mould insert and mould holder allowed temperature control and vacuum application. Replication was realized using electrical commercially available μ-IM/μ-ICM equipment. In particular, the replication at the micrometric and sub-micrometric scales has been explored. Material characterization was conducted to estimate the Cross-WLF viscosity model parameters using a nonlinear least square method. A 3D-thermal study of the heat transfer inside the mould was developed on Comsol Multiphysics to simulate the thermal distribution over the contact surface between mould and mould insert in the μ-IM process. Finally, replication results were analyzed and discussed. Obtained results at microscale show high fidelity between the moulded parts and the mould. The μ-ICM shows better results than μ-IM at the sub-micrometric scale, as the fidelity increased.

Similar content being viewed by others

References

Giboz J, Copponnex T, Mélé P (2007) Microinjection molding of thermoplastic polymers: a review. J Micromech Microeng 17(6):R96–R109

Rohde M, Derdouri A, Kamal MR (2009) Micro replication by injection-compression molding. Int Polym Process J Polym Process Soc XXIV(03):288–297

Sahli M, Millot C, Roques-Carmes C, Khan Malek C, Barrière T, Gelin JC (2009) Quality assessment of polymer replication by hot embossing and micro-injection moulding processes using scanning mechanical microscopy. J Mater Process Technol 209(18–19):5851–5861

Singh A, Metwally K, Michel G, Queste S, Robert L, Malek CK (2011) Injection moulding using an exchangeable si mould insert. Micro Nanosyst 3:230–235

Huang CK (2007) Polymeric nanofeatures of 100 nm using injection moulding for replication. J Micromech Microeng 17

Wu C-H, Chen W-S (2006) Injection molding and injection compression molding of three-beam grating of DVD pickup lens. Sensors Actuators A Phys 125

Nagato K, Hamaguchi T, Nakao M (2011) Injection compression molding of high-aspect-ratio nanostructures. J Vac Sci Technol B Microelectron Nanometer Struct 29(6):06FG10

Macintyre D, Thoms S (1998) The fabrication of high resolution features by mould injection. Microelectron Eng 41–42:211–214

Schift H, David C, Gabriel M, Gobrecht J, Heyderman LJ, Kaiser W, Köppel S, Scandella L (2000) Nanoreplication in polymers using hot embossing and injection molding. Microelectron Eng 53(1–4):171–174

Matschuk M, Bruus H, Larsen NB (2010) Nanostructures for all-polymer microfluidic systems. Microelectron Eng 87

Holzer C, Gobrecht J, Schift H, Solak H et al (20010) Replication of micro- and nanostructures on polymer surfaces. Macromol Symp 296

Brochard F, de Gennes PG (1979) Conformations de polymères fondus dans des pores très petits. J Phys Lett 40(16):399–401

Odijk T (1983) The statistics and dynamics of confined or entangled stiff polymers. Macromolecules 16(8):1340–1344

Yoshimura T, Shiraishi H, Yamamoto J, Okazaki S (1993) Nano edge roughness in polymer resist patterns. Appl Phys Lett 63(6):764–766

Allen KW (1992) Theories of adhesion. Handbook of adhesion 473–475

Kolew A, Münch D, Sikora K, Worgull M (2011) Hot embossing of micro and sub-micro structured inserts for polymer replication. Microsyst Technol 17(4):609–618

Kazmer D. Power Law Viscosity Model Fitter. [on line]. Available on: http://kazmer.uml.edu/Software/power-law.html. [visited 29-Oct-2013]

Björck A (1996) Numerical methods for least squares problems. SIAM

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Metwally, K., Barriere, T. & Khan-Malek, C. Replication of micrometric and sub-micrometric structured surfaces using micro-injection and micro-injection compression moulding. Int J Adv Manuf Technol 83, 779–789 (2016). https://doi.org/10.1007/s00170-015-7602-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7602-4