Abstract

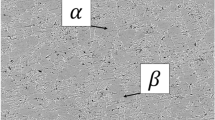

The turning of mechanical construction and bearing steels is widely carried out using PCBN and oxide ceramic tools, even when materials have high hardness (40 to 60 HRC), reached after quenching and tempering heat treatment. However, mechanical components submitted to severe abrasive loads show, in addition to matrix hardness, the presence of a high-volume fraction of hard particles in the microstructure. Turning materials with a high content of hard particles in the microstructure will result in high rates of abrasive wear or damage to the cutting edges of the tool. Information regarding the turning of materials characterized by a high-volume fraction of carbides in the microstructure is limited in literature. The objective of this study was to determine the performance of two grades of PCBN tools (high CBN and low CBN content with an added ceramic phase) in the turning of high-chromium white cast iron applying continuous and interrupted cutting. Evaluations of tools’ life, wear mechanisms at the tool cutting edges, roughness, and microstructure remaining on the turned surface were carried out. The results show that the grades with low CBN content and the addition of a ceramic phase, the tool life was three times longer than that of the grades with high CBN content. The most interesting result obtained concerns the microstructural modifications in a narrow subsurface layer of the turned material. Carbide fragmentation and alignment in the direction of the cutting shear plane were identified, which may potentiate the use of the material.

Similar content being viewed by others

References

Berns H, Theisen W (2008) Ferrous materials: steels and cast iron. Springer, Leipzig

Boing D (2010) Analysis of PCBN tool life in turning of high chromium white cast iron. Dissertation, Educational Society of Santa Catarina, http://www.sociesc.org.br/pt/pesquisa/conteudo.php?&lng=2&id=810&mnu=1323&top=0&crs=140. Accessed 20 Jan 2014

Oliveira AJ, Diniz AE, Ursolino DJ (2009) Hard turning in continuous and interrupted cut with PCBN and whisker-reinforced cutting tools. J Mater Process Technol 12–13:5262–5270

Hashimoto F, Guo YB, Warren AW (2006) Surface integrity difference between hard turned and ground surfaces and its impact on fatigue life. CIRP Ann 55:81–84

Choi Y, Liu R (2006) Rolling contact fatigue life of finish hard machined surfaces. Part 2. Experimental verification. Wear 261:492–499

Matsumoto Y, Hashimoto F, Lahoti G (1999) Surface integrity generated by precision hard turning. CIRP Ann 48:59–62

Yallese MA, Rigal J-F, Chaoui K, Boulanouar L (2005) The effects of cutting conditions on mixed ceramicand cubic boron nitride tool wear and on surface roughness during machining of X200Cr12 steel (60 HRC). Proc Inst Mech Eng B J Eng 219:35–55

Poulachon G, Bandyopadhyay BP, Jawahir IS, Pheulpin S, Seguin E (2004) Wear behavior of CBN tools while turning various hardened steels. Wear 256:302–310

Masood SH, Armitage K, Brandt M (2011) An experimental study of laser-assisted machining of hard-to-wear white cast iron. Int J Mach Tools Manuf 51:450–456

Tabrett CP (1996) The electro-discharge machining surfaces of high-chromium white irons. J Mater Sci Lett 15:1792–1794

ASTM Standard A532 (1993) Specification for steel castings, ferritic and martensitic, for pressure containing parts, suitable for low temperature service. ASTM International, West Conshohocken

Diniz AE, Oliveira AJ (2008) Hard turning of interrupted surfaces using CBN tools. J Mater Process Technol 1–3:275–281

Yallese MA, Chaoui K, Zeghib N, Lakhdar B, Rigal JF (2009) Hard machining of hardened bearing steel using cubic boron nitride tool. J Mater Process Technol 209:1092–1104

Koch KF (1996) Technologie des Hochpräzisions-Hartdrehens. Dissertation. RWTH Aachen

Grzesik W (2008) Advanced machining processes of metallic materials—theory, modelling and applications. Elsevier, Amsterdam

Smith GT (2008) Cutting tool technology. Springer, London

Arsecularatne JA, Zhang LC, Montross C, Mathew P (2006) On machining of hardened AISI D2 steel with PCBN tools. J Mater Process Technol 171:244–252

Dahl L (2010) Cubic boron nitride cutting tool insert with excellent resistance to chipping and edge fracture. United States patent US 7,670,980 B2

Malik AS (2012) Sintered cubic boron nitride cutting tool. United States patent US 2012/0000138 A1

Astakhov VP (2006) Tribology of metal cutting. Elsevier, Amsterdam

Trent EM, Wright PK (2000) Metal cutting. Butterworth-Heinemann, Woburn

Int. Org. for Standardization. ISO 3685 (1993) Tool-life testing with single-point turning tools

Grzesik W (2008) Influence of tool wear on surface roughness in hard turning using differently shaped ceramic tools. Wear 265:327–335

Klocke F, König W (2008) Fertigungsverfahren 1 - Drehen, Fräsen, Bohren, Springer

Ko TJ, Kim HS (2001) Surface integrity and machinability in intermittent hard turning. Int J Adv Manuf Technol 18:168–175

Int. Org. for Standardization. ISO 1302 (2002) Geometrical product specification (GPS)—indication of surface texture in technical product documentation.

Penalva ML, Arizmendi M, Diaz F, Fernández J, Katz Z (2002) Effect of tool wear on roughness in hard turning. CIRP Ann 51:57–60

Bouacha K, Yallese MA, Mabrouki T, Rigal JF (2010) Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int J Refract Met Hard Mater 28:349–361

Shaw MC (2004) Metal cutting principles. Oxford University Press, New York

Ren XJ, James RD, Brookes EJ, Wang L (2001) Machining of high chromium hardfacing materials. J Mater Process Technol 115:423–429

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Oliveira, A.J., Boing, D. & Schroeter, R.B. Effect of PCBN tool grade and cutting type on hard turning of high-chromium white cast iron. Int J Adv Manuf Technol 82, 797–807 (2016). https://doi.org/10.1007/s00170-015-7426-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7426-2