Abstract

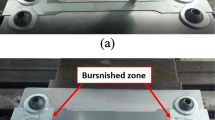

This paper explores the effects on the surface roughness, hardness and residual stress of G10380 steel specimens milled and treated with a ball-burnishing process assisted by vibrations. These vibrations are incorporated through the attachment of an induced coil module to a conventional burnishing tool, with forces transmitted through a pre-loaded spring. A positive effect of vibrations on the improvement and efficiency of the burnishing treatment is demonstrated, empirically proving that the vibrations introduce additional energy into the system that aids with displacements along the surface of the material to reallocate the crystalline structure. Significant results are found in terms of final surface roughness, which is highly improved in comparison to conventional burnishing treatments, even with fewer passes and a significant time reduction. Less robust results are observed in terms of specimen hardness and residual stress, but future improvements could be derived with a thorough development of the vibration system.

Similar content being viewed by others

References

Shepard MJ, Prevey PS, Jayaraman N (2003) Effects of surface treatment on fretting fatigue performance of Ti-6Al-4V. In: Proceedings of the 8th national turbine engine high cycle fatigue (HCF) Conference, April 14-16, Monterrey, CA

Travieso-Rodriguez JA, Dessein G, Gonzalez-Rojas HA (2011) Improving the surface finish of concave and convex surfaces using a ball burnishing process. Mater Manuf Process 26(12):1494–1502

Yinggang T, Yung CS (2007) Laser-assisted burnishing of metals. Int J Mach Tools Manuf 47:14–22

Kozlov AV, Mordyuk AV, Chernyasshevsky AV (1995) On the additivity of acoustoplastic and electroplastic effects. Mater Sci Eng 190(1-2):75–79

Siua KW, Ngana HW, Jones IP (2011) New insight on acoustoplasticity-ultrasonic irradiation enhances subgrain formation during deformation. Int J Plast 27(5):788–800

Mahmood HA (2008) The effects of ball- and roller-burnishing on the surface roughness and hardness of some non-ferrous metals. J Mater Process Technol 72(5):385–391

El-Axir MH, Othman OM, Abodiena AM (2008) Study on the inner surface finishing of aluminium alloy 2014 by ball-burnishing process. J Mater Process Technol 202:435–442

Travieso-Rodriguez JA (2010) Estudio para la mejora del acabado superficial de superficies complejas, aplicando un proceso de deformacin plstica (bruñido con bola). PhD Thesis. Universitat Politecnica de Catalunya, Barcelona (Spain)

Mech-India Engineers Pvt. Ltd. Retrieved from http://www.mechindia.com/. Last visited on 24/11/2014

Ecoroll AG Werkzeugtechnik hydrostatic tools catalogue. Retrieved from http://www.ecoroll.de/en/products/hydrostatische-werkzeuge.html. Last visited on 24/11/2014

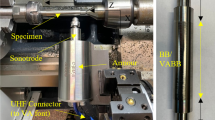

Gomez-Gras G, Travieso-Rodriguez JA, Gonzalez-Rojas HA, Napoles-Alberro A, Carrillo F, Dessein G (2014) Study of a ball-burnishing vibration-assisted process. In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol 229, no 1, pp 172–177. doi:10.1177/0954405414526383

Travieso-Rogdriguez JA, Gonzalez-Rojas HA, Casado-Lopez R (2013) Herramienta con bola a baja presin, aplicable para bruido de superficies. Spanish patent reference: P201130331. Boletín Oficial de la Propiedad Intelectual BOPI

Holstein T (1959) Theory of ultrasonic absorption in metals: the collision-drag effect. Phys Rev 113(2):479–496

Rodriguez A, Lopez de la Calle LN, Celaya A, Lamikiz A, Albizuri J (2012) Surface improvement of shafts by the deep ball-burnishing technique. Surface and Coatings Technology 206:2817–2824

Luca L (2002) Investigation into the use of ball burnishing of hardened steel components as a finishing process. PhD Dissertation, University of Toledo (USA)

Fangjung S, Chienhua C (2003) Freeform surface finish of plastic injection mould by using ball-burnishing process. J Mater Process Technol 140:248–254

Yin S, Shuinmura T (2004) A comparative study: polishing characteristics and its mechanisms of three vibration modes in vibration-assisted magnetic abrasive polishing. Int J Mach Tools Manuf 44:383–390

Roettger K (2002) Walzen hartgedrehter Oberflaechen. PhD Dissertation, RWTH Aachen University (Germany)

Travieso-Rodriguez JA, Gomez-Gras G, Jorba-Peiro J, Carrillo F, Dessein G, Alexis J, Gonzalez-Rojas H (2015) Experimental study on the mechanical effects of the vibration-assisted ball-burnishing process. Mater Manuf Process. first published on April 2015. doi:10.1080/10426914.2015.1019114

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Travieso-Rodriguez, J.A., Gomez-Gras, G., Dessein, G. et al. Effects of a ball-burnishing process assisted by vibrations in G10380 steel specimens. Int J Adv Manuf Technol 81, 1757–1765 (2015). https://doi.org/10.1007/s00170-015-7255-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7255-3