Abstract

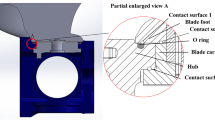

To improve the assembly accuracy of remanufactured parts with multiple heterogeneity and properties, and to guarantee the quality of remanufacturing product no worse than the original one, this paper takes the air tightness of remanufactured engines’ cylinder block and head as the research target and proposes a quality control method based on the Jacobian-torsor model for remanufacturing assembly. First of all, three different Jacobian-torsor models for assembly tolerance are structured, and according to that, the defined torsor difference (∆FR) of remanufacturing products is calculated by considering the geometric error of remanufactured related parts assembly influenced by the temperature field and force field. Then, the optimal tightening torque of cylinder heads’ main bolts corresponding to ∆FR is achieved by applying the bivariate Lagrange interpolation method. Finally, taking the assembly of remanufactured engines’ cylinder block and head as a case study to verify the proposed methods is feasible and effective.

Similar content being viewed by others

References

Xu B (2010) State of the art and future development in remanufacturing engineering. Trans Mater Heat Treat 1:003

Liu M, Liu C, Xing L, Mei F, Zhang X (2013) Study on a tolerance grading allocation method under uncertainty and quality oriented for remanufactured parts. The International Journal of Advanced Manufacturing Technology, 1–8.

Sun X, Li Y, Govindan K (2013) Integrating dynamic acquisition pricing and remanufacturing decisions under random price-sensitive returns. Int J Adv Manuf Technol 68(1–4):933–947

Ferguson M, Guide VD, Koca E, Souza G (2009) The value of quality grading in remanufacturing. Prod Oper Manag 18(3):300–314

Zhou J, Huang P, Zhu Y, Deng J (2012) A quality evaluation model of reuse parts and its management system development for end-of-life wheel loaders. J Clean Prod 35(17):239–249

Niu T (2011) Optimal model for remanufacturing tolerance design and its application. Comput Integr Manuf Syst 17(2):232–238

Chen X, Liang G, Ma S (2007) Continuous quality improvement for remanufacturing products based on PMLC. China Mech Eng 18(2):170–174

Tang X, Mao H, Li X (2011) Effect of quality uncertainty of parts on performance of reprocessing system in remanufacturing environment. J Southeast Univ 27(1):92–95

Ge M, Liu C, Liu M (2014) The online quality control methods for the assembling of remanufactured engines’ cylinder block and cover under uncertainty. The International Journal of Advanced Manufacturing Technology, 1–9.

Jin X, Hu S, Ni J, Xiao G (2013) Assembly strategies for remanufacturing systems with variable quality returns. IEEE Trans Autom Sci Eng 10(1):76–85. doi:10.1109/TASE.2012.2217741

Liu M, Liu C, Xing L, Zhang X, Wang Q, Wang X (2014) Location method for remanufactured complex mechanical products. Chinese J Mech Eng 4.50(8):150–155

Zhang Y, Yin Y, Yang M (2010) A new selective assembly approach for remanufacturing of mating parts. Computers and Industrial Engineering, 2010 40th International Conference on. IEEE, 1–6

Cai X, Lai M, Li X, Li Y, Wu X (2014) Optimal acquisition and production policy in a hybrid manufacturing/remanufacturing system with core acquisition at different quality levels. Eur J Oper Res 233(2):374–382

Su C, Xu A (2014) Buffer allocation for hybrid manufacturing/remanufacturing system considering quality grading. Int J Prod Res 52(5):1269–1284

Liu M, Liu C, Zhu Q (2014) Optional classification for reassembly methods with different precision remanufactured parts. Assem Autom 34(4):3–3

Teissandier D, Couetard Y, Gerard A (1999) A computer aided tolerancing model: proportioned assembly clearance volume. Comput Aided Des 31(13):805–817

Desrochers A, Ghie W, Laperriere L (2003) Application of a unified Jacobian-torsor model for tolerance analysis. J Comput Inf Sci Eng 3(1):2–14

Zhang W, Chen C, Li P, Li G, Hu J (2011) Tolerance modeling in actual working condition based on Jacobian-Torsor theory. Comput Integr Manuf Syst 17(1):77–83

Zhao F (2010) The structure and principle of automobile engine. Beijing Institute of Press, 6: 220 ~ 221.

Wang S, Li G, Wang H, Liu J, Xu B (2011) Influence of remelting treatment on rolling contact fatigue performance of NiCrBSi coating. Trans Mat Heat Treat 32(11):135–139

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, W., Pang, K., Liu, C. et al. The quality control method for remanufacturing assembly based on the Jacobian-torsor model. Int J Adv Manuf Technol 81, 253–261 (2015). https://doi.org/10.1007/s00170-015-7194-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7194-z