Abstract

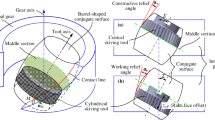

Latest research clearly demonstrates the excellent capability of the gear power skiving technology. For further improvement of the skiving process and enhancement of the process reliability, the fundamental research on the cutting mechanism of cylindrical gear power skiving was conducted. First, the kinematic model of power skiving and mathematical of tapered skiving cutter were established according to the engagement principle of crossed helical gears. Then, the simulation process and chip deformation mechanism were developed. Based on the proposed modeling, we investigated the cutting mechanism, including the cutter top rake angle related to the cut strategy, skiving accuracy with respect to the gear number, and tooth ratio. The results support the skiving cutter design and process optimization and are an important basis for the implementation of the advanced gear process.

Similar content being viewed by others

References

Kojima M (1974) Gear skiving of involute internal spur gear (part 1: on the tooth profile). Bull JSME 17(106):511–518

Kojima M (1974) On the clearance angles of skiving cutter (part 2: helical type cutter for internal spur gear skiving). Bulle JSME 17(105):401–408

Kobialka C (2012) Contemporary gear pro-machining solutions. AGMA Tech Pap, 12FTM11

Lao QC, Liu B (2014) Summary of skiving. Tool Eng 48(1):7–9

Spath D, Huhsam A (2002) Skiving for high-performance machining of periodic structures. Ann CIRP 51(1)

Fleischer J, Bechle A, Kuhlewein C (2006) Process development of skiving-a highly productive gearing process. CIRP January Meeting, Presentation STC-C, Paris

Fleischer J, Bechle A, Kuhlewein C (2006) High performance gearing by skiving. CIRP 2nd International Conference on High Performance Cutting (HPC), Canada

Volker S, Chirsttoph K, Hermann A (2011) 3D-FEM modeling of gear skiving to investigate and chip formation mechanisms. Adv Mater Res 223:46–55

Hartmut M, Olaf V (2012) Robust method for skiving and corresponding apparatus comprising a skiving tool. US patent, 20120328384A1

Hartmut M, Olaf V (2013) Semi-completing skiving method and device having corresponding skiving tool for executing a semi-completing skiving method. US patent, 20130071197A1

Li J, Chen XC, Zhang HY (2011) Slicing technology for cylindrical gears. Chin J Mech Eng-En 47(19):193–198

Chen XC, Li J, Lou BC (2013) A study on the design of error-free spur slice cutter. Int J Adv Manuf Technol 68(4):727–738

Chen XC, Li J, Lou BC (2013) Effect of the cutter parameters and machining parameters on the interference in gear slicing. Chin J Mech Eng-En 26(6):1118–1126

Chen XC, Li J, Peng W (2014) A study on the grinding of the major flank face of error-free spur slice cutter. Int J Adv Manuf Technol 72(2):425–438

Stadtfeld H (2014) Power skiving of cylindrical gears on different machine platforms. Gear Technol 1:52–62

Wu XT (2009) Principle of gearing (2th ed). Xi'an Jiaotong University Press, China

Litvin FL, Fuentes A (2004) Gear geometry and applied theory (2nd ed). Cambridge University Press, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, E., Hong, R., Huang, X. et al. Research on the cutting mechanism of cylindrical gear power skiving. Int J Adv Manuf Technol 79, 541–550 (2015). https://doi.org/10.1007/s00170-015-6816-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6816-9