Abstract

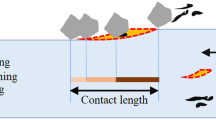

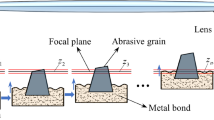

Creating scratch by an abrasive grit is mostly investigated to enhance the finishing processes. The grinding process is such that a number of abrasives with a specific statistical distribution is engaged with the workpiece and performs the material removal. If we can consider the scratching and material removal processes for a single grit indicated on the grinding wheel as a smaller element, then the material removal process could be developed and extended for every engaged abrasive edge in the grinding. In this paper, a new analytical force model for grinding process is developed by modeling abrasive grits and their interaction with the workpiece individually. Grits are examined to determine their geometrical properties and distribution on the grinding wheel. Analytical equations for total normal and tangential force components are established. Especially, the model takes into account the microstructure of the grinding wheel given by the grain geometry and the grain density. Also, the effect of kinematical parameters and process inputs on the forces will be examined. The obtained results showed that the increasing in parameters such as the slope of abrasive grits on the surface of the grinding wheel and the number of active grits on the grinding zone lead to a reduction in forces. The validity of the model can be proved by comparison of experimental results. Modeling forces in the single grit scratch will be a key factor in accurate modeling of the grinding process, and the research findings provide important information for a better understanding of the process.

Similar content being viewed by others

References

Malkin S, Cook NH (1971) The wear of grinding wheels, part1,attritious Wear. Transactions of the ASME. J Eng Ind B 93:1120–1133

Li L, Jiecai F (1981) Research on mathematical model of grinding force. Chin J Mech Eng 17(4):31–41

Badger JA, Torrance AA (2000) A comparison of two models to predict grinding forces from wheel surface topography. Int J Machine Tools Manufac 40(8):1099–1120

Hecker RL, Liang SY, Wu XJ et al (2004) Grinding force and power modeling based on chip thickness analysis. Int J Adv Manuf Technol 33(5–6):449–459

Tonshoff HK, Peters J, Inasaki I, Paul T (1992) Modelling and simulation of grinding processes. CIRP Annals-Manufac Technol 41(2):677–688

Chen Y, Tang J (2007) Research on the size effect involved in grinding. Chin Mech Eng 18(17):2033–2036

Tahsin TO, Xun C (2012) Experimental investigation of material removal mechanism in single grit grinding. Int J Mach Tools Manuf 63:32–40

Jinyuan T, Jin D, Yongping C (2009) Modeling and experimental study of grinding forces in surface grinding. journal of materials processing technology 209:2847–2854.

Patnaik US, Durgumahanti VS, Venkateswara R (2010) A new model for grinding force prediction and analysis. Int J Machine Tools & Manu 50:231–240

Warnecke, G, Zitt U R (1998) Kinematic Simulation for Analyzing and Predicting High-Performance Grinding Processes, CIRP Annals – Manufacturing Technology 47/1: 265–270.

Xie Y, Williams JA (1993) The generation of worn surfaces by the repeated interaction of parallel grooves. Wear 164:864–887

Xie Y, Williams JA (1996) The prediction of friction and wear when a soft surface slides against a harder rough surface. Wear 196:21–34

Abdolhamid A, Seyed Mehdi R, Abdolreza R (2009) Study on the rotary cup dressing of CBN grinding wheel and the grinding performance, Springer, Int J Adv Manuf Technol, DOI 10.1007/s00170-009-2227-0

Malkin S, Guo C (2008) Grinding technology–theory and applications of machining with abrasives. Industrial Press, New York

Dabrowski L, Marciniak M (2004) Investigation into phenomenological aspects of the grinding process. Proc Inst Mech Eng B J Manuf Eng 218(5):495–503

Cai R, Rowe WB (2004) Assessment of CBN wheels for precision grinding. Int J Mach Tools Manuf 44:1391–1402

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azizi, A., Mohamadyari, M. Modeling and analysis of grinding forces based on the single grit scratch. Int J Adv Manuf Technol 78, 1223–1231 (2015). https://doi.org/10.1007/s00170-014-6729-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6729-z