Abstract

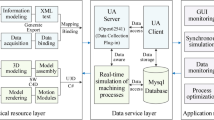

This paper presents a different web-based virtual turn-milling system, which aims to address the common problems of existed systems. The system has not only economical value, such as shortening product cycle from design to market, but also scientific interest, like proposing a new trajectory planning method. In other words, it helps sellers and buyers better understand products and enables planners and machinists to make decision or verify CNC codes much more accurate and faster. This system is made up of three levels, which is client browser, server, and database, and every level is divided into several specified functions. Among all the functions, turn-milling simulation function is the most crucial part. To enhance the system’s features, many sub-function modules are also adopted in simulation functions. Through these modules, the system implements material removal function, tool trajectory planning function, numerical control (NC) code inputting and compiling function, and so on. To realize these functions, the whole machining system is developed by using the network superiority of Java language and Virtual Reality Modeling Language (VRML) technology interaction, which will also lead to smaller data volume. Owing to the transportability of Java language and VRML technology as well as the good understandability of the system, this web-based virtual turn-milling system is also suitable to the dynamic demonstration and machining simulation of other NC machine tools. Some future research directions are given to perfect the system in the end.

Similar content being viewed by others

References

Ong SK, Mannan MA (2004) Virtual reality simulations and animations in a web-based interactive manufacturing engineering module. Comput Educ 43:361–382

Yang H, Xue D (2003) Recent research on developing web-based manufacturing systems: a review. Int J Prod Res 41(15):3601–3629

Suh S, Seo Y, Lee S (2003) Modelling and implementation of internet-based virtual machine tools. Int J Adv Manuf Tech 21(7):516–522

Xu XW, Newman ST (2006) Making CNC machine tools more open, interoperable and intelligent-a review of the technologies. Comput Ind 57:141–152

He HW, Wu YM (2009) Web-based virtual operating of CNC milling machine tools. Comput Ind 60:686–697

Kadir AA, Xu X, Hammerle E (2010) Virtual machine tools and virtual machining-a technological review. Robot Cim-int Manuf 10:1–14

Wang LH, Orban P, Cunningham A (2004) Remote real-time CNC machining for web-based manufacturing. Robot Cim-int Manuf 20:563–571

Ong SK, Jiang L, Nee AYC (2002) An Internet-based virtual CNC milling system. Int J Manuf Tech 20:20–30

Newman ST, Nassehi A (2007) Universal manufacturing platform for CNC machining. Ann CIRP 56(1):459–561

Newman ST, Nassehi A, Xu XW (2008) Strategic advantages of interoperability for global manufacturing using CNC technology. Robot Cim-int Manuf 24:699–708

Zheng L (2008) A web-based machining parameter selection system for life cycle cost reduction and product quality enhancement. Comput Ind 59:254–261

Zhu LD, Liang WL, Dong SG (2009) Research of dynamic simulation system for NC machine tool based on web. Comput Integ Manuf Syst 5:954–958 (In Chinese)

Jiang P, He QH, Wang Y (2008) Research on interactive virtual assembly technology based on VRML and JAVA. Mech Res Appl 21(6):96–99

Soori M, Arezoo B, Habibi M (2013) Dimensional and geometrical errors of three-axis CNC milling machines in a virtual machining system. Comput Aided Des 45:1306–1313

Zhu LD, Li HN, Wang WS (2013) Research on rotary surface topography by orthogonal turn-milling. Int J Adv Manuf Technol 69:2279–2292

Qin SF, Harrison R, West AA (2004) Development of a novel 3D simulation modeling system for distributed manufacturing. Comput Ind 54:69–81

Tsai WH, Chou WC (2011) An effectiveness evaluation model for the web-based marketing of the airline industry. Expert Syst Appl 38:15499–15516

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Li, H., Liang, W. et al. A web-based virtual CNC turn-milling system. Int J Adv Manuf Technol 78, 99–113 (2015). https://doi.org/10.1007/s00170-014-6649-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6649-y