Abstract

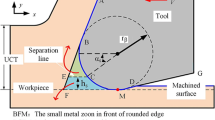

Determination of the ploughing forces is necessary for monitoring the wear of the cutting tool in micro cutting. The aim of this research was to increase the accuracy of determining the ploughing force and the determination of the influence of the uncut chip thickness on the ploughing force. A new method for determining the ploughing forces is suggested in this article. It was found that the ploughing forces determined by the new method were greater than those determined by the method comparing total forces at different flank levels of wear. It was first established that the uncut chip thickness influences the ploughing force.

Similar content being viewed by others

References

Albrecht P (1960) New developments in the theory of the metal cutting processes, part 1. The ploughing process in metal cutting. ASME J Eng Ind 82:348–357

Zorev N (1966) Metal cutting mechanics. Pergamon Press, Oxford, pp 135–180

Chae J, Park S, Freiheit T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46:313–332

Jemielniak K, Bombinski S, Aristimuno P (2008) Tool condition monitoring in micro-milling based jn hierarchical integration of signal measures. Ann CIRP 57(1):121–124

Dugin A, Popov A (2013) Increasing the accuracy of the effect of processing materials and cutting tool wear on the ploughing force values. Manuf Technol 13(2):169–173

Kalyan C, Samuel GL (2014) Cuttingmode analysis in high speed finish turning of AlMgSi alloy using edge chamfered PCD tools. J Mater Process Technol. doi:10.1016/j.jmatprotec.2014.09.003

Hui TY, Segon H, Min KL, Byung-Kwon M, Sang JL (2011) Ploughing detection in micromilling processes using the cutting force signal. Int J Mach Tools Manuf 51(5):377–382

Tasel I, Arkan T, Bao W, Mahendrakar N, Shisler B, Smith D, McCool M (2000) Tool wear estimation in micro-machining, part 1: tool usage—cutting force relationship. Int J Mach Tools Manuf 40:599–608

Afazov SM, Zdebski D, Ratchev SM, Segal J, Liu S (2013) Effects of micro-milling conditions on the cutting forces and process stability. J Mater Process Technol 213(5):671–684

Guo Y, Chou Y (2004) Determination of ploughing force and its influence on material properties in metal cutting. J Mater Process Technol 148(3):368–375

Wyen C, Wegener K, Zyust R (2010) Influence of cutting edge radius on cutting forces in machining titanium. Ann CIRP 59(1):89–92

Dugin A, Popov A (2012) Effect of the processing materials on the ploughing force values. Manuf Technol 12(13):169–173

Lipatov A, Chigirindkii Y, Kormilitsyn S (2010) Determining the cutting forces at the rear tool surface. Russ Eng Res 30(11):1158–1160

Popov A, Dugin A (2012) Experimental methods of determining the cutting forces at the tool’s rear surface. Russ Eng Res 32(1):68–69

Popov A, Dugin A (2013) A comparison of experimental estimation methods of the ploughing force in orthogonal cutting. Int J Mach Tools Manuf 65:37–40

Colwell L (1970) Methods for sensing the rate of tool wear. Ann CIRP 4:647–651

Axinte DA, Belluco W, De Chiffre L (2000) Reliable tool life measurements in turning—an application to cutting fluid efficiency evaluation. 41(7):1003–1014

De Chiffre L, Belluco W (2002) Investigations of cutting fluid performance using different machining operations. Lubr Eng 58(10):22–29

Stevenson R, Stevenson D (1995) The mechanical behavior of Zink during machining. Trans ASME J Eng Mater Technol 117:172–178

Stevenson R (1998) Measurement of parasitic forces in orthogonal cutting. Int J Mach Tools Manuf 38:113–130

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Popov, A., Dugin, A. Effect of uncut chip thickness on the ploughing force in orthogonal cutting. Int J Adv Manuf Technol 76, 1937–1945 (2015). https://doi.org/10.1007/s00170-014-6423-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6423-1