Abstract

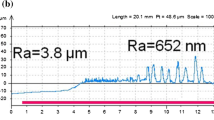

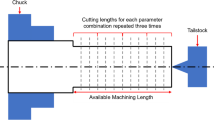

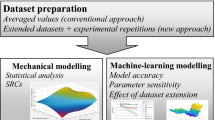

In this paper, an new way to analyze and empirically model the surface roughness of a flange geometry after a friction spinning process is presented. The friction spinning process is an innovative incremental forming technology. This new process combines thermomechanical friction elements of the friction welding process within a conventional metal spinning process. The friction allows a self-inducted heat generation and as a consequence a defined increase of formability. It is possible to produce multifunctional, complex parts from standard tubes and sheets. The process thus readily meets the demands placed on efficiency and the manufacturability of complex lightweight components. By choosing the appropriate process parameters, e.g., axial feed rate or relative motion, the contact conditions between the tool and the workpiece can be influenced in a defined way. A further advantage is the feasibility of influencing the grain structure and the hardness in a locally defined manner. It offers the possibility to manufacture finished components with the required surface roughness. Since not all parameter settings of the parameters rotation speed, head radius, feed, and tool infeed width lead to a measurable surface of the component, a gradient boosting machine will be used as classifier for predicting the valid areas of the design space. Furthermore, the influence of the tool temperature is taken into account. For the empirical modeling of the spatial distribution of the surface roughness, methods from the design and analysis of computer experiments are employed.

Similar content being viewed by others

References

Akaike H (1974) A new look at the statistical model identification. IEEE Trans Autom Control 19(6):716–723

Awiszus B, Meyer F, Meyer LW, Hahn F (2005) Erweiterung der Formgebungsgrenzen durch inkrementelle zyklische Umformung am Beispiel des Drückwalzens (Abstreckdrücken). Tagungsband zum Abschlusskolloquium des DFG Schwerpunktprogramms 1074

Bergs T, Wehrmeister T (2005) Erweiterung der Formgebungsgrenzen beim Drücken mit Laserstrahlunterstützung. In: Proceedings of the concluding symposium of the DFG (German research association) focus program, vol 1074. Verlag Mainz, Aachen, pp 119–126

Biermann D, Weinert K, Wagner T (2008) Model-based optimization revisited: towards real-world processes. In: Michalewicz Z, Reynolds R G (eds) Proceedings of the 2008 IEEE congress on evolutionary computation (CEC 2008), IEEE Press, Piscataway and NJ, pp 2980–2987

Biermann D, Gausemeier J, Hess S, Petersen M, Wagner T (2013) Planning and optimisation of manufacturing process chains for functionally graded components—part 1: methodological foundations. Prod Eng 7(6):657–664

Cressie N (1993) Statistics for spatial data, rev. Wiley, New York

Draper NR, Smith H, Pownell E (1966) Applied regression analysis, vol 3. Wiley, New York

Filice L, Fratini L, Micari F (2002) Analysis of material formability in incremental forming. CIRP Ann Manuf Technol 51(1):199–202. http://www.sciencedirect.com/science/article/pii/S0007850607614991

Friedman JH (2001) Greedy function approximation: a gradient boosting machine. Ann Stat 29(5):1189–1232

Friedman JH (2002) Stochastic gradient boosting. Comput Stat & Data Anal 38(4):367–378

Hansen N, Ostermeier A (2001) Completely derandomized self-adaptation in evolution strategies. Evol Comput 9(2):159–195

Hastie T, Tibshirani R, Friedman J (2009) The elements of statistical learning: data mining. Inference and prediction, 2nd edn. Springer Series in Statiscal, Springer, New York

Homberg W, Hornjak D (2011) Friction-spinning of tubular components—basic research on parameter influence and process design. In: Steel research international—Special Edition, 10th international conference on technology in plasticity, pp 548–553

Homberg W, Lossen B (2013) Thermal assisted incremental forming of tubes and sheets with process-integrated heat generation. In: Heim HP, Biermann D, Homberg W (eds) Functionally graded materials in industrial mass production, vol 2. Verlag Wissenschaftliche Scripten, Auerbach, pp 113–128

Homberg W, Hornjak D, Lossen B (2012) Friction-spinning — a new innovative thermal assisted incremental forming process for the manufacture of complex functionally graded workpieces. In: Heim HP, Biermann D, Maier J (eds) 1st international conference on thermo-mechanically graded materials. Verlag Wissenschaftliche Scripten, Auerbach, pp 115–120

McKay MD, Beckman RJ, Conover WJ (1979) A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics 21(2):239– 245

Montgomery DC (1997) Design and analysis of experiments, 4th edn. Wiley, New York

Music O, Allwood JM, Kawai K (2010) A review of the mechanics of metal spinning. J Mater Process Technol 210(1):3–23

Neugebauer R, Altan T, Geiger M, Kleiner M, Sterzing A (2006) Sheet metal forming at elevated temperatures. CIRP Ann Manuf Technol 55(2):793–816. http://www.sciencedirect.com/science/article/pii/S1660277306000090

Quigley E, Monaghan J (1999) An analysis of conventional spinning of light sheet metal. In: International conference on sheet metal, pp 547–554

R Core Team (2013) R: a language and environment for statistical computing. http://www.R-project.org

Ridgeway G (2012). Generalized boosted models: a guide to the gbm package. R package vignette

Ridgeway G (2013) gbm: Generalized boosted regression models. R package version 2.1. http://CRAN.R-project.org/package=gbm

Runge M (1993) Drücken und Drückwalzen. Verlag Moderne Industrie

Sacks J, Welch WJ, Mitchell TJ, Wynn HDP (1989) Design and analysis of computer experiments. Stat Sci 4(4):409–423

Stone M (1974) Cross-validatory choice and assessment of statistical predictions. J R Stat Soc Series B (Methodological) 36(2):111–147. http://www.jstor.org/stable/2984809

Wagner T, Paßmann D, Weinert K, Biermann D, Bledzki A (2008) Efficient modeling and optimisation of the property gradation of self-reinforced polypropylene sheets within a thermo-mechanical compaction process. In: Teti R (ed) 6th CIRP international conference on intelligent computation in manufacturing engineering

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hess, S., Lossen, B., Biermann, D. et al. Analysis of the surface roughness obtained in a friction spinning process based on empirical models. Int J Adv Manuf Technol 74, 1655–1665 (2014). https://doi.org/10.1007/s00170-014-6066-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6066-2