Abstract

In order to enhance the grinding precision of alumina ceramic, this paper presents the results of an experimental study of a two-step laser-assisted wet grinding process including laser-induced thermal cracking and wet grinding. In particular, the differences in grinding force, grinding force ratio, and surface finish obtained under laser-assisted wet grinding (LAWG) and conventional grinding (CG) conditions are compared and discussed. It is found that the normal and tangential grinding forces for LAWG condition are lower than for CG condition. The higher material removal rates on LAWG condition can be achieved. The average grinding force ratios for CG condition are lower than for LAWG condition. The surface roughness values are considerable in both conditions, and the improvement for surface roughness is not obvious. This is attributed to the final grinding pass through the unaffected parent material.

Similar content being viewed by others

References

Yan BH, Huang FY, Chow HM (1995) Study on the turning characteristics of alumina-based ceramics. J Mater Process Technol 54(1–4):341–347

Yin L, Huang H, Ramesh K, Huang T (2005) High speed versus conventional grinding in high removal rate machining of alumina and alumina-titania. Int J Mach Tools Manuf 45(7–8):897–907

Chen JY, Huang H, Xu XP (2009) An experimental study on the grinding of alumina with a monolayer brazed diamond wheel. Int J Adv Manuf Technol 41(1–2):16–23

Huang H, Liu YC (2003) Experimental investigations of machining characteristics and removal mechanisms of advanced ceramics in high speed deep grinding. Int J Mach Tools Manuf 43(8):811–823

Ding HT, Shin YC (2013) Improvement of machinability of waspaloy via laser-assisted machining. Int J Adv Manuf Technol 64(1–4):475–486

Ding HT, Shin YC (2010) Laser assisted machining of hardened steel parts with surface integrity analysis. Int J Mach Tools Manuf 50(1):106–114

Shen XW, Lei ST (2012) Experimental study on operating temperature in laser-assisted milling of silicon nitride ceramics. Int J Adv Manuf Technol 52(1–4):143–154

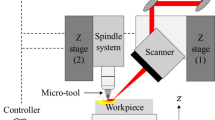

Chang W, Luo X, Zhao Q, Sun J, Zhao Y (2012) Laser assisted micro grinding of high strength materials. Key Eng Mater 496(1):44–99

Westkamper E (1995) Grinding assisted by Nd:YAG lasers. CIRP Ann Manuf Technol 44(1):317–320

Kumar M, Melkote S, Lahoti G (2010) Laser-assisted microgrinding of ceramics. CIRP Ann Manuf Technol 60(1):361–370

Yan B, Lu W, Tang R, Yang L, Yin JL (2004) Phase transformation of A12O3 ceramic coating and laser plasma spraying and laser remelting. J Chin Ceram Soc 32(7):785–788

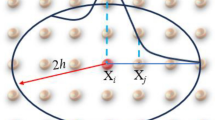

Yilbas BS, Sami M, Shuja SZ (1998) Laser-induced thermal stresses on steel surface. Opt Lasers Eng 30(1):25–37

Hanon MM, Akman E, Genc Oztoprak B, Gunes M, Taha ZA, Hajim KI, Kacar E, Gundogdu O, Demir A (2012) Experimental and theoretical investigation of the drilling of alumina ceramic using Nd:YAG pulsed laser. Opt Lasers Eng 44(4):913–922

Huang H, Liu YC, Zhou L (2003) High speed grinding of silicon nitride with resin bond diamond wheels. J Mater Process Technol 141(3):329–336

Zhang B, Fu Y (2013) Grinding of brittle materials with brazed diamond grinding wheel. Int J Adv Manuf Technol 67(9–12):2845–2852

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X.H., Chen, G.Y., An, W.K. et al. Experimental investigations of machining characteristics of laser-induced thermal cracking in alumina ceramic wet grinding. Int J Adv Manuf Technol 72, 1325–1331 (2014). https://doi.org/10.1007/s00170-014-5719-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5719-5