Abstract

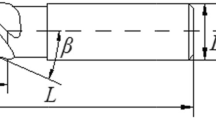

Currently, sustainable manufacturing (SM) attracts more and more attentions due to the increasing environmental pollution and energy shortage threat. Energy consumption is a fundamental element of SM for its valuable effect in the environmental impacts and business opportunities. Analyzing the relationship between process parameters and energy consumption is helpful to reduce production costs, eliminate negative environmental impacts, and increase business opportunities. Since energy consumption is impacted by the inherent uncertainties in the machining process, how to model energy consumption presents a significant challenge. Gene Expression Programming (GEP) combines the advantages of the Genetic Algorithm and Genetic Programming, and has been successfully applied in formula finding. In this paper, a Greedy Randomized Adaptive Search Procedure (GRASP)-based Gene Expression Programming, named GGEP, is proposed to predict the face milling energy consumption. In this proposed GGEP approach, a GRASP-based learning mechanism and an iterative re-start mechanism have been introduced into the basic GEP. At the basis of defining a GGEP environment for the energy consumption prediction, an explicit model has been constructed. To verify the effectiveness of the proposed approach, a case study has been conducted. The analysis of experiment results reveals that the proposed approach models and predicts the energy consumption with high accuracy and high-speed convergence. Moreover, in order to better study the mechanism of machining, the influence and contribution of different impact factors on energy consumption in face milling are analyzed.

Similar content being viewed by others

References

CECIMO (2009) Concept description for Cecimo’s self-regulatory initiative (SRI) for the sector specific implementation of the directive 2005/32/ec, PE International

Dang H, Tamayo J, Wilkinson D (2007) New Zealand energy in brief. New Zealand Ministry of Economic Development, Wellington

Yang Y, Li X, Gao L, Shao X (2013) A new approach for predicting and collaborative evaluating the cutting force in face milling based on gene expression programming. J Netw Comput Appl. doi:10.1016/j.jnca.2013.02.004

Yang Y, Li X, Jiang P, Wen L (2012) Modeling of cutting forces in a face-milling operation with gene expression programming. In, 2012. IEEE. pp. 769–774. doi: 10.1109/CSCWD.2012.6221907

Yang Y, Li X, Jiang P, Zhang L (2011) Prediction of surface roughness in end milling with gene expression programming. Proceedings of the 41st International Conference on Computers & Industrial Engineering, Los Angeles, 2011, pp. 441–446

Fisher RA (1925) Statistical methods for research workers. Oliver & Boyd, London

Benardos PG, Vosniakos GC (2002) Prediction of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot Cim-Int Manuf 18(5–6):343–354. doi:10.1016/S0736-5845(02)00005-4

Dae KB, Ko TJ, Kim HS (1997) A dynamic surface roughness model for face milling. Precis Eng 20(3):171–178. doi:10.1016/S0141-6359(97)00043-3

Diniz AE et al (1999) Influence of the relative positions of tool and workpiece on tool life, tool wear and surface finish in the face milling process. Wear 232(1):67–75. doi:10.1016/S0043-1648(99)00159-3

Lin SC, Lin RJ (1996) Tool wear monitoring in face milling using force signals. Wear 198(1–2):136–142. doi:10.1016/0043-1648(96)06944-X

Cui X, Zhao J, Tian X (2013) Cutting forces, chip formation, and tool wear in high-speed face milling of AISI H13 steel with CBN tools. Int J Adv Manuf Tech 64(9–12):1737–1749. doi:10.1007/s00170-012-4137-9

Aykut CS, Golc UM, Semiz S, Ergur HS (2007) Modeling of cutting forces as function of cutting parameters for face milling of satellite 6 using an artificial neural network. J Mater Process Tech 190(1):199–203. doi:10.1016/j.jmatprotec.2007.02.045

Li XP, Zheng HQ, Wong YS, Nee A (2000) An approach to theoretical modeling and simulation of face milling forces. J Manuf Process 2(4):225–240. doi:10.1016/S1526-6125(00)70024-7

Kim HS, Ehmann K (1993) A cutting force model for face milling operations. Int J Mach Tool Manu 33:651–673

Young H, Mathew P, Oxley PLB (1994) Predicting cutting forces in face milling. Int J Mach Tool Manu 34(6):771–783. doi:10.1016/0890-6955(94)90058-2

Zheng L, Li Y, Liang SY (1998) A generalised model of milling forces. Int J Adv Manuf Tech 14(3):160. doi:10.1007/BF01188411

Pawade RS, Sonawane HA, Joshi SS (2009) An analytical model to predict specific shear energy in high-speed turning of Inconel 718. Int J Mach Tool Manu 49(12–13):979–990. doi:10.1016/j.ijmachtools.2009.06.007

Rajemi MF, Mativenga PT, Aramcharoen A (2010) Sustainable machining: selection of optimum turning conditions based on minimum energy considerations. J Clean Prod 18(10–11):1059–1065. doi:10.1016/j.jclepro.2010.01.025

Li W, Kara S (2011) An empirical model for predicting energy consumption of manufacturing processes: a case of turning process. Proc Inst Mech Eng Part B: J Eng Manuf 225(9):1636–1646. doi:10.1177/204129751139854

Hu S, Liu F, He Y, Hu T (2012) An on-line approach for energy efficiency monitoring of machine tools. J Clean Prod 27:133–140. doi:10.1016/j.jclepro.2012.01.013

Draganescu F, Gheorghe M, Doicin CV (2003) Models of machine tool efficiency and specific consumed energy. J Mater Process Tech 141(1):9–15. doi:10.1016/S0924-0136(02)00930-5

Shao H, Wang HL, Zhao XM (2004) A cutting power model for tool wear monitoring in milling. Int J Mach Tool Manu 44:1503–1509. doi:10.1016/S0924-0136(02)00930-5

Lau H, Cheng E, Lee C, Ho G (2008) A fuzzy logic approach to forecast energy consumption change in a manufacturing system. Expert Syst Appl 34(3):1813–1824. doi:10.1016/j.eswa.2007.02.015

Armarego EJA, Ostafiev D, Wong SWY, Verezub S (2000) An appraisal of empirical modeling and proprietary software databases for performance prediction of machining operations. Mach Sci Technol 4(3):479–510. doi:10.1080/10940340008945719

Herrmann C, Thiede S (2009) Process chain simulation to foster energy efficiency in manufacturing. CIRP J Manuf Sci Technol 1(4):221–229. doi:10.1016/j.cirpj.2009.06.005

Kara S, Li W (2011) Unit process energy consumption models for material removal processes. CIRP Ann Manuf Technol 60:37–40. doi:10.1016/j.cirp.2011.03.018

Seow Y, Rahimifard S (2011) A framework for modelling energy consumption within manufacturing systems. CIRP J Manuf Sci Technol 4(3):258–264. doi:10.1016/j.cirpj.2011.03.007

Avram OI, Xirouchakis P (2011) Evaluating the use phase energy requirements of a machine tool system. J Clean Prod 19(6–7):699–711. doi:10.1016/j.jclepro.2010.10.010

Mori M, Fujishima M, Inamasu Y, Oda Y (2011) A study on energy efficiency improvement for machine tools. CIRP Ann Manuf Technol 60:145–148. doi:10.1016/j.cirp.2011.03.099

Ahilan C, Kumanan S, Sivakumaran N, Edwin Raja Dhas J (2012) Modeling and prediction of machining quality in CNC turning process using intelligent hybrid decision making tools. Appl Soft Comput 13(3):1543–1551. doi:10.1016/j.asoc.2012.03.071

Boyd G, Dutrow E, Tunnessen W (2008) The evolution of the energy star energy performance indicator for benchmarking industrial plant manufacturing energy use. J Clean Prod 16(6):709–715. doi:10.1016/j.jclepro.2007.02.024

Ferreira C (2002) Gene expression programming in problem solving. In: Editor (ed) Soft computing and industry—recent applications. Springer, London, pp. 635–654

Ferreira C (2001) Gene expression programming: a new adaptive algorithm for solving problems. Complex Syst 13(2):87–129

Feo TA, Resende MGC (1989) A probabilistic heuristic for a computationally difficult set covering problem. Oper Res Lett 2(8):67–71. doi:10.1016/0167-6377(89)90002-3

Ferreira C (2003) Function finding and the creation of numerical constants in gene expression programming. In: Benítez JM, Cordón O, Hoffmann F, Roy R (eds) Advances in soft computing. Springer, London, pp 257–265. doi:10.1007/978-1-4471-3744-3_25

Lin Y, Peng H, Wei J (2007) A niching gene expression programming algorithm based on parallel model. In: Xu M (ed) Advanced parallel processing technologies 2007, lecture notes in computer science 4847. Springer, Berlin, pp 261–270. doi:10.1007/978-3-540-76837-1_30

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

GRASP | Greedy Randomized Adaptive Search Procedure |

GGEP | GRASP-based gene expression programming |

P | Energy consumption |

V | Cutting speed |

a p | Depth of cut |

f t | Feed rate |

ORF | Open reading frames |

ET | Expression trees |

RMSD | Root mean square deviation |

n cnd | Scale of the candidate set |

c cnd | Coefficient for the scale of candidate set |

n p | Scale of population |

n cyc | Max number of the cycles for construction process |

ν | Score of individual |

c | Cost of individual |

ε | Candidate set |

RCL | Restricted candidate list |

σ∈ε | The elements in the candidate set |

g(σ) | Greedy function |

r(σ) | Serial number of element σ |

p | Probability of the element σ for being selected |

max iter | Max number of iterations of problem |

c rst | Coefficient of iterative re-start |

c rsv | Scale ratio coefficient for reservation in iterative re-start |

DPDB | Dual Passive Direct Box |

APE | Absolute percentage of error |

Rights and permissions

About this article

Cite this article

Yang, Y., Li, X., Gao, L. et al. Modeling and impact factors analyzing of energy consumption in CNC face milling using GRASP gene expression programming. Int J Adv Manuf Technol 87, 1247–1263 (2016). https://doi.org/10.1007/s00170-013-5017-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5017-7