Abstract

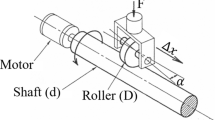

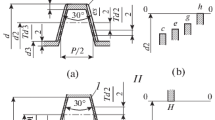

During the classical manufacturing process of conical thread surfaces with lathe center displacement, the worm shaft is driven with the help of the driving pin through the lathe fork. As a result of the shifting of the worm shaft by half cone angle, the path curve of the driving pin will be an ellipse path instead of a circle on the perpendicular plane to axis. The peripheral speed of the spindle is constant, but due to the ellipse path, the radius is constantly changing as a function of time. That is why the angular velocity and the angular rotation are also changing, and these cause pitch fluctuation during the manufacturing process of conical worms. During the manufacturing process, we have examined pitch errors which are caused by angular velocity fluctuation and we have also determined the geometrical shaping of the driving pin by which errors of the pitch can be eliminated.

Similar content being viewed by others

References

Óváriné dr. Balajti Zs (2007) Kinematikai hajtópárok gyártásgeometriájának fejlesztése, PhD értekezés, Miskolc

Dudás I, Bodzás S, Dudás I. Sz, Mándy Z (2012) Konkáv menetprofilú spiroid csigahajtópár és eljárás annak köszörüléssel történő előállítására, Szabadalmi iktatószám: P1200405, Szabadalmi bejelentés napja: 07.04

Dudás I (2012) Designing of worm gear drives in manufacturing system. J Prod Process Syst 6(1):9–12, Miskolc University Press, HU ISSN 1215–0851

Dudás I (2000) The theory and practice of worm gear drives. Penton Press, London, ISBN 1 8571 8027 5

Hegyháti J (1988) Untersuchugen zur Anwendung von Spiroidgetrieben. Diss. A. TU. Desden

Dudás I, Bodzás S (2013) Production geometry analysis, modeling and rapid prototyping production of manufacturing tool of spiroid face gear. Adv Manuf Tech 66(1–4):271–281. doi:10.1007/s00170-012-4323-9, Springer, ISSN 1433–3015 (Online), 2012.07.19. (Online), ISSN 0268–3768 (Print), (IF 1.103), http://www.springerlink.com/content/t12l4xh51g664266/?MUD=MP,http://www.springer.com/home?SGWID=0-0-1003-0-0&aqId=2362785&download=1&checkval=5131188b9d22673b4f7f1f6eb76f3a2e

Dudás I, Bodzás S (2012) Measuring technique and mathematical analysis of conical worms. Adv Manuf Tech. doi:10.1007/s00170-012-4483-7, Springer, ISSN 0268–3768, 2012.09.14., (IF 1.103), http://www.springerlink.com/content/97744668843ukp07/;http://www.springer.com/home?SGWID=0-0-1003-0-0&aqId=2388273&download=1&checkval=51c4b487d0f43b24be21924d58a0daf9

Dudley DW (1962) Gear handbook. the design, manufacture, and application of gears. McGraw-Hill, New York

Nelson WD (1961) Spiroid gearing. Mach Des 33(4):136–144, (5):93–100, (6):165–171

Litvin FL, Fuentes A (2004) Gear geometry and applied theory. Cambridge University Press, Cambridge, ISBN 978 0 521 81517 8

Litvin FL, Nava A, Fan Qi, Fuentes A (2002) New geometry of worm face gear drives with conical and cylindrical worms: generation, simulation of meshing, and stress analysis. NASA/CR—2002-211895

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

-

I.—driving pin

-

II.—spindle

-

III.—lathe fork

-

IV.—worm axis

-

δ 1—worm half cone angle

-

a—distance between the lathe fork and the worm shaft neck

-

r m —distance between the center line of the driving pin and the rotational axis ofspindle

-

x—initial distance between the contact point and the spindle

-

Δs—total path length of the contact point

-

φ p —rotation angle of spindle

Rights and permissions

About this article

Cite this article

Dudás, I., Bodzás, S. & Mándy, Z. Solving the pitch fluctuation problem during the manufacturing process of conical thread surfaces with lathe center displacement. Int J Adv Manuf Technol 69, 1025–1031 (2013). https://doi.org/10.1007/s00170-013-5010-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5010-1