Abstract

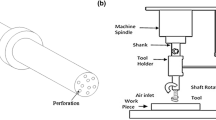

In the present trend of technological development, micro-machining is gaining popularity in the miniaturization of industrial products. In this work, a hybrid process of micro-wire electrical discharge grinding and micro-electrical discharge machining (EDM) is used in order to minimize inaccuracies due to clamping and damage during transfer of electrodes. The adaptive neuro-fuzzy inference system (ANFIS) and back propagation (BP)-based artificial neural network (ANN) models have been developed for the prediction of multiple quality responses in micro-EDM operations. Feed rate, capacitance, gap voltage, and threshold values were taken as the input parameters and metal removal rate, surface roughness and tool wear ratio as the output parameters. The results obtained from the ANFIS and the BP-based ANN models were compared with observed values. It is found that the predicted values of the responses are in good agreement with the experimental values and it is also observed that the ANFIS model outperforms BP-based ANN.

Similar content being viewed by others

References

Okuyama H, Takada H (1998) Micromachining with SR and FEL. Nuclear Instrum Methods Phys Res B 144:58–65

Matsui S, Kaito T, Fujita JI, Ishida M, Ochiai Y (2001) Three dimensional nanostructure fabrication by focused-ion-beam chemical vapor deposition. J Japan Soc Precis Eng 67(9):1412–1415

Asad ABMA, Takeshi M, Rahman M, Lim HS, Wong YS (2007) Tool-based micro-machining. J Mater Process Technol 192–193:204–211

Yeo SH, Tan LK (1999) Effects of ultrasonic vibrations in micro electro-discharge machining of microholes. J Micromech Microeng 9:345–352

DiBitonto DD, Eubank PT, Patel MR, Barrufet MA (1989) Theoretical models of the electrical discharge machining process I: a simple cathode erosion model. J Appl Phys 66(9):4095–4103

Patel MR, Barrufet MA, Eubank PT, DiBitonto DD (1989) Theoretical models of the electrical discharge machining process II: a simple anode erosion model. J Appl Phys 66(9):4104–4111

Eubank PT, Patel MR, Barrufet MA, Bozkurt B (1993) Theoretical models of the electrical discharge machining process III: the variable mass, cylindrical plasma model. J Appl Phys 73(11):7900–7909

Wang ZL, Cui JZ, Lui XF, Zhao WS (2004) Mechanism of electrode removal in short pulse time electric discharge machining. Material Science Forums 471–472:784–789

Guo ZN, Lee TC, Yue TM, Lau WS (2002) Experimental investigation into shaping particle-reinforced material by WEDM-HS. J Mater Process Technol 129(1–3):56–59

Liu HS, Yan BH, Chen CL, Huang FY (2005) Application of micro-EDM combined with high frequency dither grinding to micro-hole machining. Int J Machine Tools Manuf 20:1–8

J. Valentincic, L. Duhovnik, D. Kuser, M. Junkar, Comparison of material removal in micro and conventional EDM, Proceedings of the 9th International conference on management of innovative technologies, MIT 2007, Prian, Slovenia, 225–228

Z.Y. Yu, T. Masuzawa, M. Fujino (1998) Micro-EDM for three dimensional cavities—development of uniform wear method. Annals of the CIRP 47 (1):169–172

M. Kunieda, B.Lauwers, K.P.Rajurkar, B.M. Schumacher (2005) Advancing EDM through fundamental insight into the process Annals of the CIRP 54 (2):64–87

Wong YS, Rahman M, Lim HS, Han H, Ravi N (2003) Investigation of micro-EDM material removal characteristics using single RC-pulse discharges. J Mater Process Technol 140(1–3):303–307

A. Ivanov, C. Ferri, A. Petrelli, K. Popov (2007) Electrode wear ratio and its effect on process modeling and process capability, IPROMS2007, Third Virtual International Conference on Intelligent Production Machines and Systems, July 2007

C. Ferry, A. Petrelli, A. Ivanoc (2007) An exploratory data analysis estimation of the effects of the electrode material on the electrical discharge in micro-EDM, IPROMS2007, Third Virtual International Conference on Intelligent Production Machines and Systems, July 2007

Bigot S, Valentincic J, Blatnik O, Junkar M (2006) Micro-EDM parameters optimization. Second International Conference on Multi-material Micro manufacture, Grenoble, pp 20–22

Storn R, Price K (1995) Differential evolution—a simple and efficient adaptive scheme for global optimization over continuous spaces. Technical Report TR-95-012. International Computer Science Institute, Berkeley

Mayer D-G et al (2005) Differential evolution—an easy and efficient evolutionary algorithm for model optimization. Agric Syst 83:315–328

Carlos A.Coello Coello et al. (2007) Evolutionary algorithms for solving multi-objective problems, 2nd edn. Springer, Heidelberg

Abbass H-A, Sarker R (2002) The Pareto differential evolution algorithm. Int J Artificial Intel Tools 11(4):531–552

Babu B-V, Rakesh Angira(2002) A differential evolution approach for global optimization of MNLP problems. Proceedings of 4th Asia-Pacific Conference on Simulated Evolution and Learning(SEAL’02), Singapore, Paper No.1033, Vol.2: 880–884, November 18–22

Masuzawa T, Fujino M, Kobayashi K (1985) Wire electro-discharge grinding for micro-machining. Annals of the CIRP 34(1):431–434

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suganthi, X.H., Natarajan, U., Sathiyamurthy, S. et al. Prediction of quality responses in micro-EDM process using an adaptive neuro-fuzzy inference system (ANFIS) model. Int J Adv Manuf Technol 68, 339–347 (2013). https://doi.org/10.1007/s00170-013-4731-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4731-5