Abstract

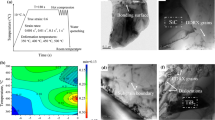

The hot deformation behaviour and microstructure evolution of stir cast 7075Al alloy and 7075Al alloy with 10, 15 and 20 % volume fraction of 20 μm SiCp composites have been studied by using the processing maps. The compression tests were conducted on both alloys and composites in the temperature range of 300–500 °C and the strain rate range of 0.001–1.0 s−1 to establish the processing map. The dynamic recrystallization and instability zones were identified and validated through micrographs. The composites showed higher flow stress, efficiency and lower instability regimes than alloy. The 15 % volume fraction of SiCp composites achieved better hot workability due to grain refinement, hardening and strengthening of the material.

Similar content being viewed by others

References

Williams JC, Starke EA (2003) Progress in structural materials for aerospace systems. Acta Mater 51(19):5775–5799

Wloka J, Hack T, Virtanen S (2007) Influence of temper and surface condition on the exfoliation behaviour of high strength Al–Zn–Mg–Cu alloys. Corros Sci 49(3):1437–1449

Ramanathan S, Karthikeyan R, Ganasen G (2006) Development of processing maps for 2124Al/SiCp composites. Mater Sci Eng, A 441:321–325

Badini C, LaVecchia GM, Fino P, Valente T (2000) Forging of 2124/SiCp composites: preliminary studies of the effect on microstructure and strength. J Mater Process Technol 116:289–297

Tham LM, Gupta M, Cheng L (2001) Effect of limited matrix–reinforcement interfacial reaction on enhancing the mechanical properties of aluminium–silicon carbide composites. Acta Mater 49:3243–3253

Tham LM, Gupta M, Cheng L (2003) Predicting the failure strains of Al/SiC composites with reacted matrix-reinforcement interfaces. Mater Sci Eng, A 354:369–376

Narayana Murty SVS, Nageswara Rao B, Kashyap BP (2005) On the hot working characteristics of 2014 Al–20 vol% Al2O3 metal matrix composite. J Mater Process Technol 166:279–285

Srinivasan N, Prasad YVRK, Ramarao P (2008) Hot deformation behaviour of Mg–3Al alloy—a study using processing map. Mater Sci Eng, A 476:146–156

Zbigniew G (2005) Deformation processing map for control of CuSi3, 9 silicon bronze microstructure. J Mater Process Technol 159:377–382

Dai LH, Ling Z, Bai YL (2001) Size-dependent inelastic behavior of particle-reinforced metal–matrix composites. Compos Sci Tech 61:1057–1063

Liu LF, Dai LH, Yang GW (2003) Strain gradient effects on deformation strengthening behavior of particle reinforced metal matrix composites. Mater Sci Eng, A 345:190–196

Lin YC, Chen M-S, Zhong J (2008) Prediction of 42CrMo steel flowstress at high temperature and strain rate. Mech Res Commun 35(3):142–150

Prasad YVRK, Rao KP (2005) Processing maps and rate controlling mechanisms of hot deformation of electrolytic tough pitch copper in the temperature range 300–950°C. Mater Sci Eng, A 391:141–150

Narayana Murty SVS, Nageswara Rao B, Kashyap BP (2003) On the hot working characteristics of 6061Al–SiC and 6061–Al2O3 particulate reinforced metal matrix composites. Compos Sci Tech 63:119–135

Frank Su YH, Chen YC, Tsao CYA (2004) Workability of spray-formed 7075 Al alloy reinforced with SiCp at elevated temperatures. Mater Sci Eng, A 364:296–304

Cavaliere P, Evangelist E (2006) Isothermal forging of metal matrix composites: recrystallization behaviour by means of deformation efficiency. Compos Sci Tech 66:357–362

Ganesan G, Raghukandan K, Karthikeyan R, Pai BC (2004) Development of processing maps for 6061 Al/15 % SiCp composite material. Mater Sci Eng, A 369:230–235

Mousavi Anijdan SH, Madaah-Hosseini HR, Bahrami A (2007) Flow stress optimization for 304 stainless steel under cold and warm compression by artificial neural network and genetic algorithm. Mater Des 28:609–615

Rao KP, Oruganti RK (2003) Study of hot deformation through energy storage concept. J Mater Process Technol 138:97–101

Seshacharyulu T, Medeiros SC, Morgan JT, Malas JC, Frazier WG, Prasad YVRK (2000) Hot deformation and microstructural damage mechanisms in extra low interstitial (ELI) grade Ti-6Al-4V. Mater Sci Eng, A 279:289–299

Ferry M (2005) In: Xiao Guo Z (ed) The deformation and processing of structural materials. Woodhead, Cambridge

Issam S, Jalham A (2005) Comparative study of some network approaches to predict the effect of the reinforcement content on the hot strength of Al–base composites. J Mater Process Technol 166:392–397

Hu HE, Zhen L, Yang L, Shao WZ, Zhang BY (2008) Deformation behavior and microstructure evolution of 7050 aluminum alloy during high temperature deformation. Mater Sci Eng, A 488:64–71

Srivastava VC, Jindal V, Uhlenwinkel V, Bauckhage K (2008) Hot-deformation behaviour of spray-formed 2014 Al + SiCP metal matrix composites. Mater Sci Eng, A 477:86–95

Zhu S, Fahrenholtz WG, Hilmas GE (2007) Influence of silicon carbide particle size on the microstructure and mechanical properties of zirconium diboride–silicon carbide ceramics. J Eur Ceram Soc 27:2077–2083

Zhang H, Li L, Yuan D, Peng D (2007) Hot deformation behavior of the new Al–Mg–Si–Cu aluminum alloy during compression at elevated temperatures. Mater Charact 58:168–173

Chawla N, Shen YL (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3:357–370

Ganesh VV, Chawla N (2005) Effect of particle orientation anisotropy on the tensile behavior of metal matrix composites: experiments and microstructure-based simulation. Mater Sci Eng, A 391:342–353

Bindumadhavan PN, Wah HK, Prabhakar O (2002) Assessment of particle–matrix debonding in particulate metal matrix composites using ultrasonic velocity measurements. Mater Sci Eng, A 323:42–51

Wang Z, Song M, Sun C, Xiao D, He Y (2010) Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al–Cu alloy composites. Mater Sci Eng, A 527:6537–6542

Schuh C, Noe LP, Dunand DC (2000) Enhanced densification of metal powders by transformation-mismatch plasticity. Acta Materialia 48:1639–1653

Hafizpour HR, Sanjari M, Simchi A (2009) Analysis of the effect of reinforcement particles on the compressibility of Al–SiC composite powders using a neural network model. Mater Des 30:1518–1523

Mazen AA, Emara MM (2004) Effect of particle cracking on the strength and ductility of Al–SiCp powder metallurgy metal matrix composites. J Mater Eng Perform 13(1):39–46

Milan MT, Bowen P (2004) Tensile and fracture toughness properties of SiCp reinforced Al alloys: effects of particle size, particle volume fraction, and matrix strength. J Mater Eng Perform 13(6):775–783

Ghosh SK, Saha P, Kishore S (2010) Influence of size and volume fraction of SiC particulates on properties of ex situ reinforced Al–4.5Cu–3 Mg metal matrix composite prepared by direct metal laser sintering process. Mater Sci Eng A 527:4694–4701

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajamuthamil selvan, M., Ramanathan, S. Effect of silicon carbide volume fraction on the hot workability of 7075 aluminium-based metal–matrix composites. Int J Adv Manuf Technol 67, 1711–1720 (2013). https://doi.org/10.1007/s00170-012-4604-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4604-3