Abstract

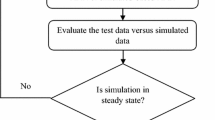

Selection of appropriate priority dispatching rules (PDRs) is a major concern in practical scheduling problems. Earlier research implies that using one PDR does not necessarily yield to an optimal schedule. Hence, this paper puts forward a novel approach based on discrete event simulation (DES) and artificial neural networks (ANNs) to decide on the optimal PDR for each machine from a set of rules so as to minimize the makespan in job shop scheduling problems. Non-identical PDRs are considered for each machine. Indeed, for a given number of machines, all permutations of PDRs are taken into account which could lead to nondeterministic polynomial-time hardness of the problem when the number of machines increases. To address this issue, DES and ANNs are employed as a meta-model. First, the problem is modeled and quite a number of feasible solutions are obtained from DES on its own. Afterward, a back-propagation neural network is developed in accordance with the results of DES to calculate the makespan based on all potential permutations of PDRs. The performance of the proposed approach is investigated through a set of test-bed problems.

Similar content being viewed by others

References

Sarin SC, Chen CS (1986) A model for manufacturing system selection. In: Kusiak A (eds) Flexible manufacturing systems: methods and studies. Amsterdam, North Holland, 99–112

Chryssolouris G, Lee M, Pierce J, Domroese M (1990) Use of neural networks for the design of manufacturing systems. Manuf Rev 3:187–194

Heragu SS (1997) Facilities design. PWS Publishing, Boston

Çakar T, Cil I (2004) Artificial neural networks for design of manufacturing systems and selection of priority rules. Int J Comput Integr Manuf 17(3):195–211

Tavakkoli-Moghaddam R, Daneshmand-Mehr M (2005) A computer simulation model for job shop scheduling problems minimizing makespan. Comput Ind Eng 48:811–823

Azadeh A, Negahban A, Moghaddam M (2011) A hybrid computer simulation-artificial neural network algorithm for optimization of dispatching rule selection in stochastic job shop scheduling problems. Int J Prod Res 50(2):551–566

Raghu TS, Rajendran C (1993) An efficient dynamic dispatching rule for scheduling in a job shop. Int J Prod Econ 32(3):301–313

Ishii N, Talavage JJ (1994) A mixed dispatching rule approach in FMS scheduling. Int J Flex Manuf Syst 6(1):69–87

Tzafestas S, Triantafyllakis A (1994) A new adaptively weighted combinatorial dispatching rule for complex scheduling problems. Comput Integr Manuf Syst 7(1):7–15

Ishii N, Muraki M (1996) An extended dispatching rule approach in an on-line scheduling framework for batch process management. Int J Prod Res 34(2):329–348

Holthaus O, Rajendran C (1997) Efficient dispatching rules for scheduling in a job shop. Int J Prod Econ 48(1):87–105

Chikamura A, Nakamae K, Fujioka H (1997) Evaluation of production dispatching rules through scheduling simulation in the final test process of LSI manufacturing system. Electron Commun Jpn Pt II Electron 80(6):34–42, English translation of Denshi Tsushin Gakkai Ronbunshi

Holthaus O, Rajendran C (1997) New dispatching rules for scheduling in a job shop—an experimental study. Int J Adv Manuf Technol 13(2):148–153

Liu KC (1998) Dispatching rules for stochastic finite capacity scheduling. Comput Ind Eng 35(1–4):113–116

Jeong KC, Kim YD (1998) A real-time scheduling mechanism for a flexible manufacturing system: using simulation and dispatching rules. Int J Prod Res 36(9):2609–2626

Chikamura A, Nakamae K, Fujioka H (1999) Effect of express lots on production dispatching rule scheduling and cost in VLSI manufacturing final test process. IEICE Trans Electron E82-C(1):86–92

Jayamohan MS, Rajendran C (2000) New dispatching rules for shop scheduling: a step forward. Int J Prod Res 38(3):563–586

Reeja MK, Rajendran C (2000) Dispatching rules for scheduling in assembly jobshops—part 1. Int J Prod Res 38(9):2051–2066

Reeja MK, Rajendran C (2000) Dispatching rules for scheduling in assembly jobshops—part 2. Int J Prod Res 38(10):2349–2360

Lee GC, Kim YD, Kim JG, Choi SH (2003) A dispatching rule-based approach to production scheduling in a printed circuit board manufacturing system. J Oper Res Soc 54(10):1038–1049

Sun RL, Ding H, Xiong Y, Du R (2004) Iterative learning scheduling: a combination of optimization and dispatching rules. J Manuf Technol Manag 15(3):298–305

Dominic PDD, Kaliyamoorthy S, Kumar MS (2004) Efficient dispatching rules for dynamic job shop scheduling. Int J Adv Manuf Technol 24(1–2):70–75

Choi BK, You NK (2006) Dispatching rules for dynamic scheduling of one-of-a-kind production. Int J Comput Integr Manuf 19(4):383–392

Parthanadee P, Buddhakulsomsiri J (2010) Simulation modeling and analysis for production scheduling using real-time dispatching rules: a case study in canned fruit industry. Comput Electron Agric 70(1):245–255

Lu HL, Huang GQ, Yang HD (2011) Integrating order review/release and dispatching rules for assembly job shop scheduling using a simulation approach. Int J Prod Res 49(3):647–669

Zhang CY, Li P, Guan Z, Rao Y (2007) A tabu search algorithm with a new neighborhood structure for the job shop scheduling problem. Comput Oper Res 34(11):3229–3242

Liu H, Dong J (1996) Dispatching rule selection using artificial neural networks for dynamic planning and scheduling. J Intell Manuf 7(3):243–250

Caskey K, Storch RL (1996) Heterogeneous dispatching rules in job and flow shops. Prod Plan Control 7(4):351–361

Min H-S, Yih Y (2003) Selection of dispatching rules on multiple dispatching decision points in real-time scheduling of a semiconductor wafer fabrication system. Int J Prod Res 41(16):3921–3941

El-Bouri A, Shah P (2006) A neural network for dispatching rule selection in a job shop. Int J Adv Manuf Technol 31(3–4):342–349

Marimuthu S, Ponnambalam SG, Jawahar N (2007) Tabu search and simulated annealing algorithms for scheduling in flow shops with lot streaming. Proc Inst Mech Eng B J Eng Manuf 221:317–331

Pan Q-K, Wang L, Qian B (2008) A novel multi-objective particle swarm optimization algorithm for no-wait flow shop scheduling problems. Proc Inst Mech Eng B J Eng Manuf 222:519–539

Pritsker AAB, O’Reilly JJ (1999) Simulation with Visual SLAM and AweSim. Wiley, New York

Fonseca DJ, Navaresse DO, Moynihan GP (2003) Simulation meta-modeling through artificial neural networks. Eng Appl Artif Intell 16(3):177–183

Hornik K, Stinchcombe M, White H (1989) Multilayer feed-forward networks are universal approximators. Neural Netw 2(5):359–366

Funahashi K (1989) On the approximate realization of continuous mappings by neural networks. Neural Netw 2(3):183–192

Zobel CW, Keeling KB (2008) Neural network-based simulation meta-models for predicting probability distributions. Comput Ind Eng 54(4):879–888

Kuo Y, Taho Y, Peters BA, Chang I (2007) Simulation meta-model development using uniform design and neural networks for automated material handling systems in semiconductor wafer fabrication. Simul Model Pract Theory 15(8):1002–1015

Vig MM, Dooley KJ (1993) Mixing static and dynamic flow time estimates for due-date assignment. J Oper Manag 11(1):67–79

Hill T, Remus W (1994) Neural network models for intelligent support of managerial decision making. Decis Support Syst 11(5):449–459

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azadeh, A., Shoja, B.M., Moghaddam, M. et al. A neural network meta-model for identification of optimal combination of priority dispatching rules and makespan in a deterministic job shop scheduling problem. Int J Adv Manuf Technol 67, 1549–1561 (2013). https://doi.org/10.1007/s00170-012-4589-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4589-y