Abstract

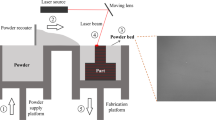

Laser milling (LM) can be classified as a layer manufacturing process in which the material is removed by a laser beam by means of the ablation mechanism. It is a laser machining process which uses a laser beam to produce 3D shapes into a wide variety of materials. It is also known as laser ablation. It shows clear advantages versus the traditional milling such as the unlimited choice of materials, the direct use of computer-aided design structure data, the high geometric flexibility, and the touchless tool. LM requires the selection of optimal machining parameters for the job. Unlike the mechanical milling and the mechanical incision, the depth of the single removed layer is chosen at the beginning as input parameter of the process. In LM, the ablated depth depends from the process parameters such as laser power, scan speed, pulse duration, and pulse frequency. This work aims to develop an algorithm that can predict the parameters necessary to execute the material removal with a preset ablation depth. Using the results of an experimental campaign, the laser milling process was modeled by means of a back-propagation artificial neural network. Then, an iterative algorithm, based on the previous trained neural network, permitted to calculate the scanning velocity and pulse frequency that approached for the best the preset ablation depth. The developed approach represents a mean for the rational selection of laser ablation process parameters. It can be performed in an intuitive manner since it uses simple artificial intelligence like the artificial neural network.

Similar content being viewed by others

References

Pham DT, Dimov SS, Petkov PV, Dobrev T (2005) Laser milling for micro-tooling. CU IMRC Working Paper Series, Cardiff University, UK

Pham DT, Dimov SS, Ji C, Petkov PV, Dobrev T (2004) Laser milling as a “rapid” micromanufacturing process. Proc Inst Mech Eng J Eng Manuf 218(Part B):1–7

Heyl P, Olschewski T, Wijnaendts RW (2001) Manufacturing of 3D structures for micro-tools using laser ablation. Microelectron Eng 57(58):775–780

Riccardi G, Cantello M, Mariotti F, Giacosa P (1998) Micro-machining with excimer laser. CIRP Ann 47(1):145–148

Windholz R, Molian P (1997) Nanosecond pulsed excimer laser machining of CVD diamond and HOPG graphite. J Mater Sci 32:4295–4301

Kovalenko V, Anyakin M, Uno Y (2000) Modelling and optimisation of laser semiconductor cutting. Proc ICALEO Laser Micro-Fabr 90:D82–D92

Karnakis D, Rutterford G, Knowles M, Dobrev T, Petkov P, Dimov S (2006) High quality laser milling of ceramics, dielectrics and metals using nanosecond and picosecond lasers. SPIE Photonics West LASE 2006, San Jose CA, USA, 6106

Kaldos A, Pieper HJ, Wolfb E, Krause M (2004) Laser machining in die making—a modern rapid tooling process. J Mater Process Technol 155(156):1815–1820

Campanelli SL, Ludovico AD, Bonserio C, Cavalluzzi P, Cinquepalmi M (2007) Experimental analysis of the laser milling process parameters. J Mater Process Technol 191:220–223

Campanelli SL, Ludovico AD, Deramo C (2007) Dimensional accuracy optimisation of the laser milling process. Proceedings of the 26 International Congress on Applications of Lasers and Electro–Optics (ICALEO), Orlando, Florida

Mannio P, Magee J, Coyne E, O’Connor GM (2003) Ablation thresholds in ultrafast laser micro-machining of common metals in air. Proc SPIE 4876:470–478

Ganesan T, Vasant P, Irraivan E (2011) Solving engineering optimization problems with KKT Hopfield neural networks. Int Rev Mech Eng 7(7):1333–1339

Olabi AG, Casalino G, Benyounis KY, Rotondo A (2007) Minimisation of the residual stress in the heat affected zone by means of numerical methods. Mater Des 28(8):2295–2302

Olabi AG, Casalino G, Benyounis KY, Hashmi MSJ (2006) An ANN and Taguchi algorithms integrated approach to the optimization of CO2 laser welding. Adv Eng Softw 37(10):643–648

Casalino G, Curcio F, Minutolo FMC (2005) Investigation on Ti6Al4V laser welding using statistical and Taguchi approaches. J Mater Process Technol 167(2–3):422–428

Yousef BF, Knopf GK, Bordatchev EV, Nikumb SK (2003) Neural network modeling and analysis of the material removal process during laser machining. Int J Adv Manuf Technol 22(1–2):41–53

Luo H, Zeng H, Hu L, Hu X, Zhou Z (2005) Application of artificial neural network in laser welding defect diagnosis. J Mater Process Technol 170(1–2):403–411

Casalino G, Minutolo FMC (2004) A model for evaluation of laser welding efficiency and quality using an artificial neural network and fuzzy logic. Proc Inst Mech Eng B J Eng Manuf 218(6):641–646

Park YW, Rhee S (2008) Process modeling and parameter optimization using neural network and genetic algorithms for aluminum laser welding automation. Int J Adv Manuf Technol 37(9–10):1014–1021

Kuhl M (2002) From macro to micro—the development of laser ablation. Proceedings of ICALEO 2002

Tsai CH, Chen HW (2003) Laser milling of cavity in ceramic substrate by fracture-machining element technique. J Mater Process Technol 136:158–165

Gillner A, Holtkamp J, Hartmann C, Olowinsky A, Gedicke J, Klages K, Bosse L, Bayer A (2005) Laser applications in microtechnology. J Mater Process Technol 167:494–498

Fausett L (1994) Fundamentals of neural networks: architectures, algorithms and applications. Prentice-Hall, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Campanelli, S.L., Casalino, G., Ludovico, A.D. et al. An artificial neural network approach for the control of the laser milling process. Int J Adv Manuf Technol 66, 1777–1784 (2013). https://doi.org/10.1007/s00170-012-4457-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4457-9