Abstract

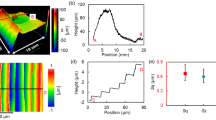

Atmospheric pressure plasma polishing (APPP) is developed for the final finishing of high quality ultra-smooth surfaces. To improve surface quality, formation mechanism of ultra-smooth surfaces in APPP is studied. Quantum chemistry simulation is used to investigate the interaction between atoms. Simulation of single Si-F bonding process indicates 0.2 eV difference of binding energy between convex and concave models, which reflects the reaction probability of convex structure is higher than that of concave structure. By comparing the spatial atomic configuration and species diffusion path, it is also demonstrated convex topography should be removed faster than concave topography. So roughness of optical surfaces can be reduced further to form ultrasmooth surfaces. And experimental results accord well with theoretical analysis. Detected by atomic force microscopy every 40 s, the average maximum height of surface is testified to decrease faster than the maximum depth obviously, which makes the whole surface going toward a new equilibrium status with lower roughness. Another experiment proves the average surface roughness decreases from Ra 4.529 to 0.926 nm after 100 s continuous machining. And the stereo images also indicate obvious improvement of surface topography. Moreover, free outmost electron is proved to be helpful to promote chemical reaction by simulation, so fresh surfaces may be more favorable for APPP which makes sample preparation more purposeful.

Similar content being viewed by others

References

Zhang JF, Wang B, Dong S (2007) A new development of ultra-smooth surface machining technology. Opt Tech 33:150–154

Li BG, Xiong CY, Li CG, Zhang QR (2006) Machining technology of super smooth surface. Manuf Technol Mach Tool 6:60–66

Golini D, Jacobs SD (1991) Physics of loose abrasive microgrinding. Appl Opt 30:2761–2777

Pahk HJ, Stout K, Blunt L (2010) A comparative study on the three-dimensional surface topography for the polished surface of femoral head. Int J Adv Manuf Technol 51:439–452

Senthilkumar C, Ganesan G, Karthikeyan R (2009) Study of electrochemical machining characteristics of Al/SiCp composites. Int J Adv Manuf Technol 43:256–263

Zhang JF, Wang B, Dong S (2008) Design of the atmospheric pressure plasma polishing system for the machining of ultra-smooth surfaces. Nanotechnol Precis Eng 6:222–226

Fanara C, Shore P, Nicholl JR (2006) A new reactive atom plasma tehcnology (RAPT) for precision machining: the etching of ULE optical surfaces. Adv Eng Mater 8:933–939

Mori Y, Yamamura K, Endo K, Yamauchi K, Yasutake K, Goto H, Kakiuchi H, Sano Y, Mimura H (2005) Creations of perfect surfaces. J Cryst Growth 275:39–50

Wang B, Zhang JF, Dong S (2008) The application of the atomic emission spectroscopy analysis in the atmospheric pressure plasma polishing process study. Spectrosc Spectr Anal 28:1641–1644

Zhang JF, Wang B, Dong S (2008) Analysis of factors impacting atmospheric pressure plasma polishing. Int J Precis Eng Manuf 9:39–43

Mimura H, Yumoto H, Matsuyama S, Yamamura K, Sano Y (2005) Relative angle determinable stitching interferometry for hard X-ray reflective optics. Rev Sci Instrum 76:045102

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Li, B., Wang, B. et al. Analysis on formation mechanism of ultra-smooth surfaces in atmospheric pressure plasma polishing. Int J Adv Manuf Technol 65, 1239–1245 (2013). https://doi.org/10.1007/s00170-012-4253-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4253-6