Abstract

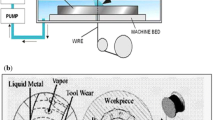

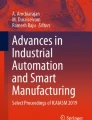

Due to the presence of large number of process variables and complicated stochastic nature, selection of optimum machining parameter combinations for obtaining higher material removal rate with minimum overcut and surface roughness is a challenging task in Micro Wire Electric Discharge Machining (μ-WEDM). The important parameters of Material Removal Rate (MRR), overcut and surface roughness are considered in this study of single pass μ-WEDM machining of aluminium. The system model is created with statistical based regression analysis using experimental data. This system model is employed to maximize the material removal rate and minimize the surface roughness and overcut using Simulated Annealing (SA) scheme. Finally consistency of the method is tested with trial values. The model is found as capable of predicting the response characteristics as a function of different control variables. Experiments are carried out to check the validity of the developed model and then optimal parametric combinations are searched out using an advanced optimization strategy.

Similar content being viewed by others

References

Ho KH, Newman ST (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tool Manufact 44:1247–1259

Huang JT, Liao YS (2000) A wire-EDM maintenance and fault-diagnosis expert system integrated with an artificial neural network. Int J Prod Res 38(5):1071–1082

Kurikose S, Shanmugham MS (2005) Multiobjective optimization of wire EDM process by non dominated sorting genetic algorithms. J Mater Process Tech 170:133–141

Yan J, Wang K, Tao YF (2008) Reliable multi-objective optimization of high speed WEDM process based on Gaussian process regression. Int J Mach Tool Manufact 48:47–60

Gauri SK, Chakraborty S (2009) Optimize the multiple responses of WEDM process using weighted principle components. Int J Adv Manuf Technol 40:1102–1110

Manna A, Bhattacharya B (2006) Taguchi and Gauss elimination method: a dual response approach for parametric optimization of CNC wire cut EDM of PRAISiCMMC. Int J Adv Manuf Technol 28:67–75

Liu JW, Yue TM, Guo ZN (2009) Wire electrochemical discharge machining of Al2O3 particle reinforced aluminum alloy 6061. Mater Manuf Process 24(4):446–453

Huang JT, Liao YS (2003) Optimization of machining parameters of wire EDM based on Grey relational and statistical analysis. Int J Prod Res 41(8):1707–1720

Sadiq MA, Rahman M, Lim HS (2008) Study of WEDM parameter phenomena for microfabrication. Int J Manuf Manag 13(2–3):226–240

Ali MY, Sami MA (2008) Experimental study of conventional wire electrical discharge machining for microfabrication. Mater Manuf Process 23(7):641–645

Mathew J, Somashekhar KP, Sooraj VS, Subbarao N, Ramachandran N (2009) Effect of work material and machining conditions on the accuracy and quality of micro holes. IJAT 2(3):279–298

Somashekhar KP, Ramachandran N, Mathew J (2009) Modeling and optimization of process parameters in micro Wire EDM by Genetic Algorithm. Adv Mater Res 76–78:566–570

Somashekhar KP, Ramachandran N, Mathew J (2010) Optimization of material removal rate in micro electric discharge machining process using artificial neural network and genetic algorithms. Mater Manuf Process 25(6):467–475

Somashekhar KP, Ramachandran N, Mathew J (2010) Material removal characteristics of microslot (kerf) geometry in μ-WEDM on aluminum. Int J Adv Manuf Technol. doi:10.1007/s00170-010-2645-z

Metropolis N, Rosenbluth A, Rosenbluth N, Teller A, Teller E (1953) Equation of state calculation by fast computing machines. J Chem Phys 21:1087–1092

Kirkpatrick S, Gelatt CD, Vecchi MP (1983) Optimization by simulated annealing. Science 220:671–680

Glover F, Gary AK (2003) Hand book of metaheuristics. Kluwer, London

Van PJ, Laarhoven EHA (1987) Simulated annealing: theory and applications. Kluwer, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Somashekhar, K.P., Mathew, J. & Ramachandran, N. A feasibility approach by simulated annealing on optimization of micro-wire electric discharge machining parameters. Int J Adv Manuf Technol 61, 1209–1213 (2012). https://doi.org/10.1007/s00170-012-4096-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4096-1