Abstract

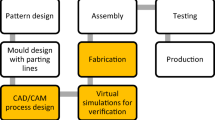

Three-dimensional printing (3DP) is widely considered to be one of the low-cost additive manufacturing (AM) processes. In this paper, the suitability of 3DP for making tooling for the vacuum-assisted resin transfer moulding (VARTM) process is considered. This combination has potential advantages, since VARTM has significant prototyping benefits if it can be combined with a fast and low cost tooling option. This paper presents a new process chain for the manufacture of closed mould composite parts using the VARTM process. It will be shown that 3DP tooling is significantly less accurate than CNC machined tooling, but there is a cost and time advantage to making tooling with 3DP. The mould life is also limited to typically 15 to 30 parts since significant wear occurs in the manufacturing process. Quantitative data are presented to show the effect of treating the mould surface to improve the surface roughness and to determine the mould life. An aspect often lacking in AM research is cost estimation. Here, the first cost model for rapid tooling for VARTM using 3DP moulds is presented and compared to actual results. It is shown that the model is suitable for design for manufacture analysis.

Similar content being viewed by others

References

Alexander P, Allen S, Dutta D (1998) Part orientation and build cost determination in layered manufacturing. CAD Plus 30(5):343–356

Bassoli E, Atzeni E (2009) Direct metal rapid casting: mechanical optimization and tolerance calculation. Rapid Prototyping J 15(4):238–243

Boothroyd G, Dewhurst P, Knight W (1994) product design for manufacture and assembly. Marcel Dekker, New York

Bryden B, Wimpenny D, Pashby I (2001) Manufacturing production tooling using metal laminations. Rapid Prototyping J 7(1):42–51

Campbell I, Combrinck J, de Beer D, Barnard L (2008) Stereolithography build time estimation based on volumetric calculations. Rapid Prototyping J 14(5):271–279

Chua C, Leong K, Lim C (2003) Rapid prototyping: principles and applications, 2nd edn. World Scientific, River Edge

di Angelo L, di Stefano P (2010) Parametric cost analysis for web-based e-commerce of layer manufactured objects. Int J Prod Res 48(7):2127–2140

Dimitrov D, Schreve K (2002) Rapid prototyping of a differential housing using 3D printing technology. In: International conference on manufacturing automation, Hong Kong, pp 483–490

Dimitrov D, Schreve K, de Beer N (2006) Advances in three dimensional printing—state of the art and future perspectives. Rapid Prototyping J 12(3):136–147

Dimitrov D, Schreve K, Taylor A, Vincent B (2007) Rapid prototyping driven design and realisation of large components. Rapid Prototyping J 13(2):85–91

Dippenaar D (2010) A technical and economical evaluation of RP technology for RTM tooling. Master’s thesis, Stellenbosch University, Stellenbosch, South Africa

Dippenaar D, Schreve K (2009) A technical and economical evaluation of RP technologies for complex RTM tooling. In: RAPDASA 10th annual international conference on competitive tooling. East London, South Africa

Ferreira J, Simoes L, Borges J, Beira R (2005) Rapid development of composite prototypes with rapid tooling in soft materials. In: Bártolo P (ed) Proceedings of the 2nd international conference on advanced research and rapid prototyping, virtual modeling and rapid manufacturing: advanced research in virtual and rapid prototyping. Leiria, Portugal, pp 291–296

Hugo P (2008) Suitability of layer manufacturing technologies for rapid tooling development in investment casting. Master’s thesis, Stellenbosch University, Stellenbosch, South Africa

Kai CC, Howe CT, Hoe EK (1998) Integrating rapid prototyping and tooling with vacuum casting for connectors. Int J Adv Manuf Technol 14:617–623

Koorevaar A (2002) Fast accurate reliable 3D reactive RTM simulation. In: ISCM 2002 proceedings. Dutch Aerospace Laboratories (NLR), Vollenhove, The Netherlands

Koorevaar A (2002) Simulation of liquid injection moulding. In: Proceedings of SAMPE 2002

Lan H, Ding Y, Hong J, Huang H, Lu B (2008) Web-based quotation system for stereolithography parts. Comput Ind 59(8):777–785

Levy GN, Schindel R, Kruth J (2003) Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann Manuf Technol 52(2):589–609

Liu HP, Su J, Li XJ (2011) Process analysis for rapid tooling technology based on rapid prototyping. Adv Mat Res 216:798–803

Lyons B (2006) Permanent and sacrificial 3DP molds for composite parts. Rapid Prototyping J 12(1):1–4

Ma S, Gibson I, Balaji G, Hu G (2007) Development of epoxy matrix composites for rapid tooling applications. J Mater Process Technol 75:192–193

Nagahanumaiah Subburaj K, Ravi B (2008) Computer aided rapid tooling process selection and manufacturability evaluation for injection mold development. Comput Ind 59(2–3):262–276

Pessard E, Mognol P, Hascot J, Gerometta C (2008) Complex cast parts with rapid tooling: rapid manufacturing point of view. Int J Adv Manuf Technol 39:898–904

Pham D, Wang X (2000) Prediction and reduction of build times for the selective laser sintering process. Proc Inst Mech Eng B J Eng Manuf 214(6):425–430

Rahmati S, Rezaei MR, Akbari J (2009) Design and manufacture of a wax injection tool for investment casting using rapid tooling. Tsinghua Sci Technol 14(Supplement 1):108–115

Ruud N (1995) Rapid tooling for resin transfer moulding. In: Proceedings of Sixth International Conference on Rapid Prototyping, pp 205–215

Singh R (2010) Three dimensional printing for casting applications: a state of art review and future perspectives. Adv Mat Res 83–86:342–349

Tari MJ, Bals A, Park J, Lin MY, Hahn HT (1998) Rapid prototyping of composite parts using resin transfer molding and laminated object manufacturing. Compos Part A Appl Sci Manuf 29(5–6):651–661

Ullman D (2003) The mechanical design process, 3rd edn. McGraw Hill, New York

Vaezi M, Safaeian D, Chua C (2011) Gas turbine blade manufacturing by use of epoxy resin tooling and silicone rubber molding techniques. Rapid Prototyping J 17(2):107–115

Veldsman G (1995) Aspects of design for manufacturability in RTM. Master’s thesis, Stellenbosch University, Stellenbosch, South Africa

Veldsman G, Basson A (1998) The role of cost estimation in the design for RTM. In: Proceedings of ECCM-8. Naples, Italy

Veldsman G, Basson A (1999) Designing for RTM using manufacturing cost estimation models. In: Proceedings of the 1999 CIRP International Design Seminar. Enschede, The Netherlands, pp 321–330

Xu F, Wong YS, Loh HT (2001) Toward generic models for comparative evaluation and process selection in rapid prototyping and manufacturing. J Manuf Syst 19(5):283–296

Zhang H, Wang G, Luo Y, Nakaga T (2001) Rapid hard tooling by plasma spraying for injection molding and sheet metal forming. Thin Solid Films 390(1–2):7–12

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dippenaar, D.J., Schreve, K. 3D printed tooling for vacuum-assisted resin transfer moulding. Int J Adv Manuf Technol 64, 755–767 (2013). https://doi.org/10.1007/s00170-012-4034-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4034-2