Abstract

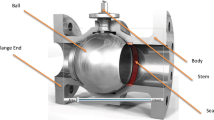

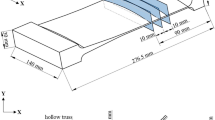

The boring of valve seats of internal combustion engines is done approximately 25 million times per year in Brazil. Excessive vibrations during this operation are common and can adversely affect dimensional and geometrical tolerances of the valve seats. The sealing of the combustion chamber is prejudiced, resulting in loss of power and higher emission of pollutant gases, harming the environment. The raw material of the valve seats is sintered steel of 370–410 HB hardness and is machined with expensive polycrystalline cubic boron nitride blades. In order to avoid the generation of excessive vibration or chatter during machining, operators reduce cutting speed and feed rate, which consequently causes reduction of productivity. In this context, investigation of the process was performed with the objective of minimizing the vibrations during the valve seat boring through changes in the tool holder design and in geometry of the cutting blades. The proposed modifications resulted in a remarkable reduction in magnitude of the resultant cutting force, vibrations, and roundness deviations of the valve seat. Hence, the sealing between the valve and the seat was improved and the emission of gases from the motor could be reduced, with gains in efficiency. The results also showed that the cutting blade edge must have a 60-μm honing, and the best cutting parameters are in the range: cutting speed 80–100 m/min and feed rate 0.04–0.08 mm/rev/tooth.

Similar content being viewed by others

References

OICA (2008). The International Organization of Motor Vehicle Manufacturers. http://www.oica.net/wp-content/uploads/world-ranking-2008.pdf. Acessed 8 December 2009.

Karpat Y, Özel T (2007) Mechanics of high speed cutting with curvilinear edge tools. Int J Mach Tools & Manuf 48:195–208

Zhou JM, Walter H, Andersson M, Stahl JE (2003) Effect of chamfer angle on wear of CBN cutting tool. Int J Mach Tools & Manuf 43(3):301–305

Chen L, El-Wardany TI, Nasr M, Elbestawi MA (2006) Effects of edge preparation and feed when hard turning a hot work die steel with polycrystalline cubic boron nitride tools. CIRP Annals—Manuf Tech 55(1):89–93

Deshpande A, Venkatachalam A, Joshi K, Chen S, Young B, Alloo R, Jawahir IS (2008) Maximizing tool life in powder metal valve seat machining through performance-based tool geometry optimization. 3rd CIRP International Conference on High Performance Cutting, Dublin, Ireland, June: 12–13

Li Y, Liang SY, Petrof RC, Seth BB (2000) Force modelling for cylindrical plunge cutting. Int J Adv Manuf 16:863–870

Kountanya R, Al-Zkeri I, Altan T (2009) Effect of tool edge geometry and cutting conditions on experimental and simulated chip morphology in orthogonal hard turning of 100Cr6 steel. J Mat Proc Tech 209(11):5068–5076

Yen Y-C et al (2004) A finite element analysis of orthogonal machining using different tool edge geometries. J Mat Proc Tech 146:72–81

Özel T, Hsu T, Zeren E (2005) Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Tech 25(3):262–269

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lacerda, H.B., Siqueira, I.L. Blade geometry effects on the boring of valve seats of internal combustion engines. Int J Adv Manuf Technol 63, 269–280 (2012). https://doi.org/10.1007/s00170-012-3905-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-3905-x