Abstract

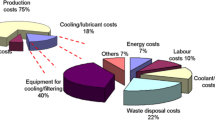

Effective lubrication and cooling is necessary to ensure grinding temperature levels not to become excessive during grinding process. Conventional grinding fluid has negative influences on the working environment in terms of the health of the machine operator. Furthermore, the using of grinding fluid is seen to increase production cost due to fluid purchase and disposal. One attractive alternative is the minimum quantity lubrication (MQL) grinding. In this study, oil–water was applied in the MQL grinding and the grinding results were compared with those of wet, dry, and pure oil MQL grinding. It is found that MQL grinding in comparison to dry grinding significantly enhances grinding performance in terms of improving the quality of the ground workpiece and reducing grinding temperature and forces. Compared with pure oil MQL grinding, the grinding temperature and the thickness of the affected layer for oil–water MQL grinding are lower. However, the tangential force and surface roughness for oil–water MQL grinding are higher than that for pure oil MQL grinding. This indicates that the former has a better cooling condition than the latter, but the lubrication capacity is contrary.

Similar content being viewed by others

References

Malkin S, Guo C (2008) Grinding technology: theory and application of machining with abrasives. Industrial, New York

Mao C, Zhou ZX, Zhang J, Huang XM, Du DY (2011) An experimental investigation of affected layers formed in grinding of AISI 52100 steel. Int J Adv Manuf Technol 54(5):515–523

Oliveira JFG, Alves SM (2006) Development of environmentally friendly fluid for CBN grinding. Annals of the CIRP 55:343–346

Morgan MN, Jackson AR, Wu H, Baines-Jones V, Batako A, Rowe WB (2008) Optimisation of fluid application in grinding. Annals of the CIRP 57:363–366

Mao C, Zhou ZX, Ren YH, Zhang B (2010) Analysis and FEM simulation of temperature field in wet surface grinding. Mater Manuf Process 25(6):399–406

Tawakoli T, Westkaemper E, Rabiey M (2007) Dry grinding by special conditioning. Int J Adv Manuf Technol 33:419–424

Tasdelen B, Thordenberg H, Olofsson D (2003) An experimental investigation on contact length during minimum quantity lubrication (MQL) machining. J Mater Process Technol 133:21–25

Weiner K, Inasaki I, Sutherland JW, Wakabayashi T (1993) Dry machining and minimum quantity lubrication. Annals of the CIRP 42:39–43

Asif I, He N, Iqbal K, Li L, Naeem UD (2008) Modeling the effects of cutting parameters in MQL-employed finish hard-milling process using D-optimal method. J Mater Process Technol 199:379–390

Dhar NR, Kamruzzaman M, Ahmed M (2006) Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J Mater Process Technol 172:299–304

Tasdelen B, Wikblom T, Ekered S (2008) Studies on minimum quantity lubrication (MQL) and air cooling at drilling. J Mater Process Technol 200:339–346

Tawakoli T, Hadad MJ, Sadeghi MH, Daneshi A, Stockert S, Rasifard A (2009) An expermental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication-MQL grinding. Int J Mach Tools Manuf 49:924–932

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Influence of oil mist parameters on minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 50:521–531

Tawakoli T, Hadad MJ, Sadeghi MH (2010) Investigation on minimum quantity lubricant-MQL grinding of 100Cr6 hardened steel using different abrasive and coolant-lubricant types. Int J Mach Tools Manuf 50:698–708

Silva LR, Bianchi EC, Fusse RY, Catai RE, Franca TV, Aguiar PR (2009) Analysis of surface integrity for minimum quantity lybricant-MQL in grinding. Int J Mach Tools Manuf 47:412–418

Silva LR, Bianchi EC, Catai RE, Fusse RY, Franca TV, Aguiar PR (2005) Study on the behavior of the minimum quantity lubricant-MQL technique under different lubricating and cooling conditions when grinding ABNT 4340 steel. J Braz Soc Mech Sci Eng XXVII:192–199

Barczak LM, Batako ADL, Morgan MN (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50:977–985

Alves JAC, Fernandes UB, Junior CES, Bianchi EC, Aguiar PR (2009) Application of the minimum quantity lubrication (MQL) technique in the plunge cylindrical grinding operation. J Braz Soc Mech Sci Eng XXXI:1–4

Hwang H, Kompella S, Chandrasekar S, Farris TN (2003) Measurement of temperature field in surface grinding using infra-red (IR) imaging system. ASME J Tribol 125:377–383

Ueda T, Yamada K, Sugita T (1992) Measurement of grinding temperature of ceramics using infrared radiation pyrometer with optical fiber. ASME J Eng Ind 114:317–322

Walton IM, Stephenson DJ, Baldwin A (2006) The measurement of grinding temperatures at high specific material removal rates. Int J Mach Tools Manuf 46:1617–1625

Batako AD, Rowe WB, Morgan MN (2005) Temperature measurement in high efficiency deep grinding. Int J Mach Tools Manuf 45:1231–1245

Nee AYC, Tay AO (1981) On the measurement of surface grinding temperature. Int J Mach Tools Manuf 34:279–291

Han S, Melkote SN, Haluska MS et al (2008) White layer formation due to phase transformation in orthogonal machining of AISI 1045 annealed steel. Mater Sci Eng A 488:195–204

Griffiths BJ (1985) White layer formations at machined surfaces and their relationship to white layer formations at worn surfaces. J Tribol 107:165–171, Transactions of the ASME

Yang SM, Tao WQ (2007) Heat transfer theory. Higher Education, Bei Jing

Brinksmeier E, Heinzel C, Wittmann M (1999) Friction cooling and lubrication in grinding. Annals of the CIRP 48:581–598

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mao, C., Tang, X., Zou, H. et al. Experimental investigation of surface quality for minimum quantity oil–water lubrication grinding. Int J Adv Manuf Technol 59, 93–100 (2012). https://doi.org/10.1007/s00170-011-3491-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3491-3