Abstract

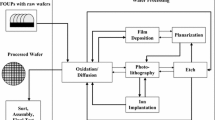

The scheduling of families of semiconductor wafers within the inspection department of a company producing electronic devices is considered in this paper. Changing the family of wafers to be inspected by an inspection machine requires a sequence-dependent set-up time; furthermore, due to the limited space availability of the inspection area, the available interoperational buffer capacity between the inspection machines is finite. The objective of the scheduling is the maximization of inspection department productivity, measured through the sequence makespan. A permutational flowshop group-scheduling problem (GSP) with sequence-dependent set-up times and limited interoperational buffer capacity has been taken into account. A benchmark of process scenarios considering different numbers of inspection machines wafers codes and families to be inspected has been generated. A Genetic Algorithm is here proposed as an efficient tool to solve the investigated problem. A comparison with a tabu search and a Nawaz, Enscore, and Ham procedure improving the currently available scheduler tool within the inspection department has been performed on the benchmark of problems. Finally, the influence on line productivity due to the finite interoperational buffer capacity is investigated.

Similar content being viewed by others

References

Baker KR (1990) Scheduling groups of jobs in the two machine flowshop. Math Comput Model 13:29–36. doi:10.1016/0895-7177(90)90368-W

Campbell HG, Dudek RA, Smith ML (1970) A heuristic algorithm for the n job, m machine sequencing problem. Manage Sci 16:630–637. doi:10.1287/mnsc.16.10.B630

Ching-Chin C, Yu-Lien L (2003) Family-Based Scheduling Rules of a Sequence-Dependent Wafer Fabrication System. IEEE Trans Semicond Manuf 16(1)

Dannenbring DG (1977) An evaluation of flow shop sequencing heuristics. Manage Sci 23:1174–1182. doi:10.1287/mnsc.23.11.1174

França PM, Gupta JND, Mendes AS, Moscato P, Veltink KJ (2005) Evolutionary algorithms for scheduling a flowshop manufacturing cell with sequence dependent family setups. Comput Ind Eng 48(3):491–506. doi:10.1016/j.cie.2003.11.004

Glover F (1989) Tabu search part I. ORSA J Comput 1:190–206

Hitomi K, Ham I (1976) Operations scheduling for group technology applications. Ann CIRP 25(1):419–422

Johnson S (1954) Optimal two and three-stage production schedules with set-up times included. Nav Res Logistic Q 1:61–68. doi:10.1002/nav.3800010110

Lee YF, Jiang ZB, Liu HR (2009) Multiple-objective scheduling and real-time dispatching for the semiconductor manufacturing system. Comput Oper Res 36:866–884. doi:10.1016/j.cor.2007.11.006

Lin JT, Wang FK, Lee WT (2004) Capacity-constrained scheduling for a logic IC final test facility. Int J Prod Res 42:79–99. doi:10.1080/0020754032000123588

Logendran R, deSzoeke P, Barnard F (2006) Sequence-dependent group scheduling problems in flexible flow shops. Int J Prod Econ 102:66–86. doi:10.1016/j.ijpe.2005.02.006

Nawaz M, Enscore EE, Ham I (1983) A heuristic algorithm for the m-machine, n-job flow-shop sequencing problem. Omega 11:91–95. doi:10.1016/0305-0483(83)90088-9

Norman BA (1999) Scheduling flowshops with finite buffers and sequence dependent setup times. Comput Ind Eng 36:163–177. doi:10.1016/S0360-8352(99)00007-8

Nowicki E (1999) The permutation flow shop with buffers. A tabu search approach. Eur J Oper Res 116:205–219. doi:10.1016/S0377-2217(98)00017-4

Ovacik IM, Uszoy R (1994) Rolling horizon algorithms for a single-machine dynamic scheduling problem with sequence-dependent set-up time. Int J Prod Res 32:1243–1263. doi:10.1080/00207549408956998

Ovacik IM, Uszoy R (1995) Rolling horizon procedures for dynamic parallel machine scheduling with sequence-dependent set-up time. Int J Prod Res 33:3137–3192. doi:10.1080/00207549508904867

Papadimitrou CH, Kanellakis PC (1980) Flowshop scheduling with limited temporary storage. J Assoc Comput Machinery 27:533–554

Ruiz R, Maroto C, Alcaraz J (2005) Solving the flowshop scheduling problem with sequence dependent setup times using advanced metaheuristics. Eur J Oper Res 165:34–54

Ruiz R, Maroto C (2006) A genetic algorithm for hybrid flowshops with sequence dependent setup times and machine eligibility. Eur J Oper Res 169:781–800

Schaller JE (2000) A comparison of heuristics for family and job scheduling in a flow-line manufacturing cell. Int J Prod Res 38(2):287–308

Schaller JE (2001) A new lower bound for the flow shop group scheduling problem. Comput Ind Eng 41:151–161

Schaller JE, Gupta JND, Vakharia AJ (2000) Scheduling a flowline manufacturing cell with sequence dependent family setup times. Eur J Oper Res 125:324–329

Shridar J, Rajendran C (1994) A genetic algorithm for family and job scheduling in a flow-line manufacturing cell. Comput Ind Eng 27:469–472

Skorin-Kapov J, Vakharia A (1993) Scheduling a flow-line manufacturing cell: a tabu search approach. Int J Prod Res 31:1721–1734

Uszoy R, Martin Vega LA, Lee CY, Leonard PA (1991) Production scheduling algorithm for a semiconductor test facility. IEEE Trans Semicond Manuf 4:270–280

Uszoy R, Church LK, Ovacik IM, Hinchman J (1993) Performance evaluation of dispatching rules for semiconductor testing operations. J Electron Manuf 3:95–105

Vakharia AJ, Chang YL (1990) A simulated annealing approach to scheduling a manufacturing cell. Nav Res Logist 37:559–577

Wemmerlov U, Vakharia AJ (1991) Job and family scheduling of a flow-line manufacturing cell: a simulation study. IIE Trans 23(4):383–392

Yang DL, Chern MS (2000) Two-machine flowshop group scheduling problem. Comput Oper Res 27:975–985

Zhang H, Jiang ZB, Guo CT, Liu HR (2006) EOPN-based real-time scheduling simulation platform of wafer fabrication system. Journal of Shanghai Jiaotong University 40(11):1857–1863

Wang L, Zhang L, Zheng DZ (2006) An effective hybrid genetic algorithm for flow shop scheduling with limited buffers. Comput Oper Res 33:2960–2971

Qian B, Wang L, Huang D, Wang W, Wang X (2009) An effective hybrid DE-based algorithm for multi-objective flow shop scheduling with limited buffers. Comput Oper Res 36:209–233

Pranzo M (2004) Batch scheduling in a two-machine flow shop with limited buffer and sequence independent setup times and removal times. Eur J Oper Res 153:581–592

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Celano, G., Costa, A. & Fichera, S. Constrained scheduling of the inspection activities on semiconductor wafers grouped in families with sequence-dependent set-up times. Int J Adv Manuf Technol 46, 695–705 (2010). https://doi.org/10.1007/s00170-009-2112-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2112-x