Abstract

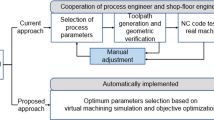

An octree-based (numerical control) NC simulation (Oct-OAC) system developed for end milling has two major applications: (1) NC verification and (2) optimization of the cutting parameters, viz., spindle speed, N (s−1), and feed rate, f (ms−1). Oct-OAC has a geometric modeling module to simulate the geometry of material removal process. Every object in the machining environment such as cutter, instantaneous workpiece, swept volume, etc. is stored as octree, an inexact representation of solid. Using this module, one can predict the geometry of the material removed at any instant of time and update the geometry of the blank subsequently. Optimization of cutting parameters using Oct-OAC is achieved through optimization module using a mechanistic model for computation and prediction of the cutting forces at any instant. The basic input for this module is the geometry of the contact surface between the cutter and workpiece which comes from the geometric modeling module using an octree-based solid modeler. It is through this contact surface that the cutting forces are passed from the workpiece onto the cutter and vice versa. The mechanistic modeling module can predict the instantaneous cutting forces from the instantaneous contact geometry and other process parameters like material combination of cutter–workpiece, parameters defining cutter geometry, and current cutting parameters such as N and f. Using this prediction, it will modify the cutting parameters for maximizing the material removal rate. This way, the mechanistic modeling module does what an adaptive controller will do with the help of force sensing. Therefore, the NC program optimization done using the Oct-OAC system is actually off-line adaptive control.

Similar content being viewed by others

References

CGTech, USA, the developers of image-based NC simulation package VeriCut. http://www.cgtech.com

CNC Software Inc., the developer of Mastercam software. http://www.mastercam.com

Anderson AO (1978) Detecting and elimination collisions in NC machining. Comput-Aided Des 10(4):231–237

Wang WP, Wang KK (1986) Real time verification of multiaxis NC programs with raster graphics. Proceedings of IEEE, International Conference on Robotics and Automation, San Francisco, 7–10 April, pp 166–171

Van Hook T (1986) Real time shaded NC milling display. Comput Graph (Proc. SIGGRAPH) 20(4):15–20

Atherton PR, Earl C, Fred C (1987) A graphical simulation system for dynamic five-axis NC verification. Proc Autofact, SME, Dearborn, MI, pp 2.1–2.12

Jerard RB, Angleton JM, Drysdale RL, Su P (1990) The use of surface points sets for generation, simulation, verification and automatic correction of NC machining programs. Proceedings of NSF Design and Manufacturing Systems Conference, Tempe, AZ, Society of Manufacturing Engineers, pp 143–1, Jan. 8–12

Chappel IT (1983) Use of vectors to simulate material removed by NC milling. Comput-Aided Des 15(3):156–158

Oliver JH, Goodman ED (1990) Direct dimensional NC verification. Comput-Aided Des 22(1):3–10. doi:10.1016/0010-4485(90)90023-6

Jerard RB, Hussaini SZ, Drysdale RL, Schaudt B (1989) Approximate methods for simulation and verification of numerically controlled machining programs. Vis Comput 5:329–348. doi:10.1007/BF01999101

Drysdale RL, Jerard RB, Schaudt B, Hauck K (1989) Discrete simulation of NC machining. Algorithmica 4(1):33–60. doi:10.1007/BF01553878

Sungertekin VA, Voelcker H (1986) Graphical simulation and automatic verification of NC machining programmes. International Conference on Robotics and Automation, pp 156–165

Spence A, Altinas Y (1991) End milling force algorithms for CAD systems. CIRP Ann 40:31–34. doi:10.1016/S0007-8506(07)61927-1

Spence AD, Altinas Y (1994) A solid modeler based milling process simulation and planning system. Trans ASME 116:61–69. doi:10.1115/1.2919377

Roth D, Ismail F, Bedi S (2003) Mechanistic modeling of the milling process using an adaptive depth buffer. Comput-Aided Des 30(8):1–17

Feng H-Y, Menq LM, Chai H, Hang ZL (1995) The prediction of dimensional error for sculptured surface production using the ball-end milling process. Int J Mach Tools Manuf 35(8):1149–1169. doi:10.1016/0890-6955(94)00044-K

Mounayri HEI, Spence AD, Elbestawi MA (1998) Milling process simulation—a generic solid modeller based paradigm, journal of manufacturing science and engineering. Trans ASME 120:213–221

Fleisig RV, Spence AD (2005) Techniques for accelerating B-Rep based parallel machining simulation. Comput-Aided Des 37:1229–1240. doi:10.1016/j.cad.2004.11.008

Vergeest JSM, Walstra WH, Bronsvoort WF (1994) Interactive simulation of robot milling for rapid shape prototyping. Comput Graph (ACM) 18(6):861–871. doi:10.1016/0097-8493(94)90013-2

Liu C, Esterling DM, Fontdecaba J, Mosel E (1996) Dimensional verification of NC machining profiles using extended quadtrees. Comput-Aided Des 28(11):845–85. doi:10.1016/0010-4485(95)00077-1

Ayala D, Brunet P, Juan R, Navazo I (1985) Object representation by means of nonminimal division quadtrees and octrees. ACM Trans Graph 4(1):41–59. doi:10.1145/3973.3975

Brunet P, Navazo I (1990) Solid representation and operation using extended octrees. ACM Trans Graph 9(2):170–197. doi:10.1145/78956.78959

Carlbom I, Chakravarty I, Vanderschel D (1985) A hierarchical data structure for representing the spatial decomposition of 3D Object. IEEE Comput Graph Appl 5:24–31

Kondo M (1994) Decomposition of complex geometry for a manufacturing application. Comput-Aided Des 26(3):244–252. doi:10.1016/0010-4485(94)90047-7

Leu MC, Park SH, Wang KK (1986) Representation of swept volumes and its applications. J Eng Ind Trans ASME 108(2):113–119

Roy U, Xu Y (1999) Computation of geometric model of a machined part from its NC machining program. Comput-Aided Des 31:401–411. doi:10.1016/S0010-4485(99)00039-1

Takata S, Tsai MD, Sata T (1989) A cutting simulation system for machinability evaluation using a work piece model. CIRP Ann 38(1):417–420

Kline WA, Devor RE, Lindberg JR (1982) The prediction of the cutting forces in end milling with application to cornering cuts. Int J Mach Tools Manuf 22(1):7–22

Takata S (1993) Generation of a machining scenario and its applications to intelligent machining operations. CIRP Ann 42(1):531–534. doi:10.1016/S0007-8506(07)62502-5

Jerad RB, Fussel BK, Hemmett (2001) Robust feedrate selection for 3 axis NC machining using discrete models, ASME. J Manuf Sci Eng 123:214–223. doi:10.1115/1.1365398

Mounayri HEI, Spence AD, Elbestawi MA (1998) Milling process simulation—a generic solid modeller based paradigm. J Manuf Sci Eng 120:213–221

FeatureCAM. http://www.featurecam.com

Website of Delcam, the developer of Powermill. http://www.delcam.com

Karunakaran KP, Shringi R (2008) A solid model-based off-line adaptive controller for feed rate scheduling for milling process. J Mater Process Technol 204:384–396. doi:10.1016/j.jmatprotec.2007.11.092

Pressman RS, William JE (1977) Numerical control and computer-aided manufacturing. Wiley, USA

Dhande SG, Karunakaran KP (1994) Symbolic and computational conjugate geometry of a generic cutter and machine tool assembly. J Des Manuf 4:167–186

Meghar D (1983) Geometric modeling using octree encoding. Comput Graph Image Process 24:160–181. doi:10.1016/0734-189X(83)90041-5

Karunakaran KP, Shringi R (2006) Octree-to-BRep conversion for volumetric NC simulation. Int J Adv Manuf Technol 32(1–2):116–131. doi:10.1007/s00170-005-0310-8

Karunakaran KP (2000) Swept volume of a generic cutter. Proc Inst Mech Eng B, J Eng Manuf 214:915–938. doi:10.1243/0954405001517991

Koenigsberger F, Sabberwal AJP (1961) An investigation into the cutting force pulsations during milling operations. Int J Mach Tool Des Res 1:15–33. doi:10.1016/0020-7357(61)90041-5

Armarego EJA, Despande NP (1989) Computerized predictive cutting models for forces in end milling including eccentricity effects. CIRP Ann 38:45–49. doi:10.1016/S0007-8506(07)62649-3

Armarego EJA, Whitefield RC (1985) Computer based modeling of popular machining operations for force and power prediction. CIRP Ann 34(1):65–69. doi:10.1016/S0007-8506(07)61725-9

Yang M, Park H (1991) The prediction of cutting force in ball end milling. Int J Mach Tools Manuf 31(1):45–54. doi:10.1016/0890-6955(91)90050-D

Altintas Y, Lee P (1996) A general mechanics and dynamics model for helical end mills. CIRP Ann 45(1):59–64. doi:10.1016/S0007-8506(07)63017-0

Lazoglu I, Lyang SY (2000) Modeling of ball end milling forces with cutter axis inclination. J Manuf Sci Eng 122(1):3–11. doi:10.1115/1.533540

Tlusty J, Smith S (1991) An overview of modeling and simulation of the milling process. Trans ASME 113:169–175

Sabberwal AJP (1962) Cutting forces in down milling. Int J Mach Tool Des Res 2:27–41

Sutherland JW, Devor RE (1986) An improved method for cutting force and surface error prediction in flexible end milling systems. J Eng Ind Trans ASME 108:269–279

Metal Carboloy Systems Department (1980) Milling handbook of high efficiency metal cutting. General Electric Company, Detroit

Martellotti ME (1941) An analysis of the milling process. Trans ASME 63:677–700

Yucesan G, Altintas Y (1996) Prediction of ball end milling forces. Trans ASME 118:95–103

Budak E, Altintas Y, Armarego EJA (1996) Prediction of milling forces from orthogonal cutting data. Trans ASME 118:261–224. doi:10.1115/1.2824057

Liao CL, Tsai JS (1994) Dynamic response analysis in end milling using pre-twisted beam finite elements. J Mater Process Technol 40:407–432. doi:10.1016/0924-0136(94)90465-0

Tarng YS, Shyur YY (1993) Identification of radial depth of cut in numerical control pocketing routines. Int J Mach Tools Manuf 33(1):1–11. doi:10.1016/0890-6955(93)90059-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karunakaran, K.P., Shringi, R., Ramamurthi, D. et al. Octree-based NC simulation system for optimization of feed rate in milling using instantaneous force model. Int J Adv Manuf Technol 46, 465–490 (2010). https://doi.org/10.1007/s00170-009-2107-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2107-7