Abstract

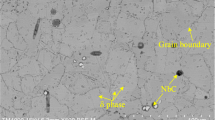

This paper presents an experimental study on the adhesive wear of a milling insert with complex groove when milling 3Cr-1Mo-1/4V and 0Cr18Ni9 steels. Experimental measurements of milling temperature and milling force were performed. Then the adhesive behaviors and mechanisms between the steels and uncoated carbide were analyzed and discussed. It is found that the high temperature gradient, thermal stress, alternate compressive stress, and tensile stress in cut-in and cut-out, provide a situation for adhesion. Some suggestions for avoiding adhesive wear and the mechanism of adhesive wear of the insert are presented.

Similar content being viewed by others

References

Deshayes L (2007) Analysis of an equivalent tool face for the cutting speed range prediction of complex grooved tools. J Mater Process Technol 190(1–3):251–262, doi:10.1016/j.jmatprotec.2007.02.037

Tan G, Liu G, Li Z, Liu MJ, Li GH, Rong YM (2004) 3D temperature field analysis and fuzzy comprehensive evaluation for milling insert with complex groove. Chin J Mech Eng 40(3):106–110

Ee KC, Balaji AK, Jawahir IS (2003) Progressive tool-wear mechanisms and their effects on chip-curl/chip-form in machining with grooved tools: an extended application of the equivalent toolface (ET) model. Wear 255(7–12):1404–1413

Jawahir IS, Li PX, Ghosh R, Exner EL (1995) A new parametric approach for the assessment of comprehensive tool-wear in coated grooved tools. CIRP Ann 45(1):49–54, doi:10.1016/S0007-8506(07)62273-2

Fontalvo GA, Humer R, Mitterer C, Sammt K, Schemmel I (2006) Microstructural aspects determining the adhesive wear of tool steels. Wear 260(9–10):1028–1034, doi:10.1016/j.wear.2005.07.001

Groche P, Nitzsche G (2007) Influence of temperature on the initiation of adhesive wear with respect to deep drawing of aluminum-alloys. J Mater Process Technol 191(1–3):314–316, doi:10.1016/j.jmatprotec.2007.03.098

Sun F, Li Z, Jiang D, Chen B (1998) Adhering wear mechanism of cemented carbide cutter in the intervallic cutting of stainless steel. Wear 214(1):79–82, doi:10.1016/S0043-1648(97)00203-2

Jawahir IS, Ghosh R, Balaji AK, Li PX (2000) Predictability of tool failure modes in turning with complex grooved tools using the equivalent toolface (ET) model. Wear 244(1–2):94–103, doi:10.1016/S0043-1648(00)00447-6

Yang LJ (2007) Modeling transient adhesive wear of tungsten carbide inserts tested with an angular setting. Tribology Int 40(7):1075–1088, doi:10.1016/j.triboint.2006.10.005

Wu JM, Lin SJ, Yeh JW, Chen SK, Huang YS, Chen HC (2006) Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 261(5–6):513–519, doi:10.1016/j.wear.2005.12.008

Ipek R (2005) Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). J Mater Process Technol 162–163:71–75, doi:10.1016/j.jmatprotec.2005.02.207

Aksoy M, Yilmaz O, Korkut MH (2001) The effect of strong carbide-forming elements on the adhesive wear resistance of ferritic stainless steel. Wear 249(8):639–646, doi:10.1016/S0043-1648(01)00686-X

Lau KH, Li KY (2006) Correlation between adhesion and wear behaviour of commercial carbon based coating. Tribology Int 39(2):115–123, doi:10.1016/j.triboint.2005.04.008

Swanson MT (2005) Geometry and kinematics of adhesive wear in brittle strike-slip fault zones. J Struct Geol 27(5):871–887, doi:10.1016/j.jsg.2004.11.009

Turhan H (2005) Adhesive wear resistance of Cu–Sn–Zn–Pb bronze with additions of Fe, Mn and P. Mater Lett 59(12):1463–1469, doi:10.1016/j.matlet.2004.11.016

Bijwe J, Rattan R (2007) Carbon fabric reinforced polyetherimide composites: optimization of fabric content for best combination of strength and adhesive wear performance. Wear 262(5–6):749–758, doi:10.1016/j.wear.2006.08.011

Larbi ABC, Cherif A, Tarres MA (2005) Improvement of the adhesive wear resistance of steel by nitriding quantified by the energy dissipated in friction. Wear 258(5–6):712–718, doi:10.1016/j.wear.2004.09.058

Astakhov VP (2007) Effects of the cutting feed, depth of cut, and workpiece (bore) diameter on the tool wear rate. Int J Adv Manuf Technol 34(7–8):631–640, doi:10.1007/s00170-006-0635-y

Liu G, Tan G, Li G (2007) Experiment, modeling, and analysis for temperature field of milling insert. Int J Adv Manuf Technol. doi:10.1007/s00170-07-1322-3

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, G., Liu, G. & Li, G. Experimental study on adhesive wear of milling insert with complex groove. Int J Adv Manuf Technol 44, 631–637 (2009). https://doi.org/10.1007/s00170-008-1856-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1856-z