Abstract

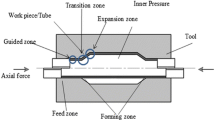

Tube hydroforming of thin-walled parts ratio of the thickness to the diameter is too low and mainly depends on the process control parameters (the internal pressure and the axial feeding). These parameters determine the occurrence of forming limits, such as wrinkling and bursting. Trial-and-error method is not a convenient method to find loading path since it is costly. Convectional loading paths, which may easily result in a product with defects, cannot be used in this case. In this study, the loading path for hydroforming process of copper joint is determined using a fuzzy controller. The final goal is to obtain a calibrated product without any wrinkling or tearing. It is shown that the wrinkling, except severe wrinkling, is a repairable defect, while bursting is an irreparable defect. Simulation of the process is done by using finite element method in combination with a designed fuzzy controller. The Abaqus scripting interface is used for modeling the part and communicating with the Abaqus kernel. The explicit method is utilized to overcome convergence problems encountered in the implicit method.

Similar content being viewed by others

References

Ahmetoglu M, Altan T (2000) Tube hydroforming: state-of-the-art and future trends. J Mater Process Technol 98:25–33 doi:10.1016/S0924-0136(99)00302-7

Dohmann F, Hartl C (1996) Hydroforming-a method to manufacture light-weight parts. J Mater Process Technol 60:669–676 doi:10.1016/0924-0136(96)02403-X

Doege E, Kosters R, Ropers C (1998) Determination of optimised control parameters for internal high pressure forming processes with the FEM. In: Proceedings of the International Conference Sheet Metal ‘98, Twente, The Netherlands, vol. 2, pp. 119–128

Manabe K, Miyamoto S, Koyama H (2003) Application of database-assisted fuzzy adaptive process control system to hydroforming process, intelligence in a materials world—selected papers from IPMM-2001. CRC, Boca Raton, FL, pp 537–543

Manabe K, Suetakea, M, Koyamab H, Yang M (2006) Hydroforming process optimization of aluminum alloy tube using intelligent control technique. Int J Mach Tools Manuf 46:1207–1211 doi:10.1016/j.ijmachtools.2006.01.028

Aydemir A, de Vree JHP, Brekelmans WAM, Geers MGD, Sillekens WH, Werkhoven RJ (2005) An adaptive simulation approach designed for tube hydroforming processes. J Mater Process Technol 159:303–310 doi:10.1016/j.jmatprotec.2004.05.018

Zimmermann HJ (1995) Fuzzy set theory and its applications, third edition. Kluwer, Norwell, MA

Johnson KI, Nguyen B, Davies RW et al (2004) A numerical process control method for circular-tube hydroforming prediction. Int J Plast 20:1111–1137 doi:10.1016/j.ijplas.2003.10.006

Strano M, Jirathearanat S-G, Shr TA (2004) Virtual process development in tube hydroforming. J Mater Process Technol 146:130–136 doi:10.1016/S0924-0136(03)00853-7

Chu E, Xu Y (2004) Hydroforming of aluminum extrusion tubes for automotive applications$ Part I: buckling, wrinkling and bursting analyses of aluminum tubes. Int J Mech Sci 46:263–283 doi:10.1016/j.ijmecsci.2004.02.014

Brush DO, Almroth BO (1975) Buckling of bars, plates, and shells. McGraw-Hill, New York

Hutchinson JW, Neale KW (1985) Wrinkling of curved thin sheet metal. Proceedings of International Symposium on Plastic Instability, Considere Memorial, pp. 71–78.

Koc M, Altan T (2002) Prediction of forming limits and parameters in the tube hydroforming process. Int J Mach Tools Manuf 42:123–138 doi:10.1016/S0890-6955(01)00048-7

Zhang H, Liu D (2006) Fuzzy modeling and fuzzy control. Birkhäuser, Boston

Vasant PM (2006) Fuzzy production planning and its application to decision making. J Intell Manuf 17:5–12 doi:10.1007/s10845-005-5509-x

Vasant P, Barsoum NN (2006) Fuzzy optimization of units products in mix-product selection problem using fuzzy linear programming approach, soft computing—a fusion of foundations. Methodol Appl 10:144–151

Aue U, Lan Y, Ngaile G, Altan T (2004) Optimizing tube hydroforming using process simulation and experimental verification. J Mater Process Technol 146:137–143 doi:10.1016/S0924-0136(03)00854-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadi, F., Mosavi Mashadi, M. Determination of the loading path for tube hydroforming process of a copper joint using a fuzzy controller. Int J Adv Manuf Technol 43, 1–10 (2009). https://doi.org/10.1007/s00170-008-1697-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1697-9