Abstract

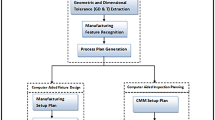

Fixture planning is an important aspect of process planning. The steps involved in automatic fixture planning are manufacturing feature recognition, setup planning and fixture configuration planning. In the present work, an integrated setup and fixture planning system is developed for minimum tolerances at critical regions using a data exchanged part model as an input. A platform-independent STEP-based automatic feature recognition system that can recognize both design and manufacturing features, including intersecting features is implemented. An automatic setup planning module is developed for generating setup plans for complete machining of a given component. A fixture planning module is developed applying the criteria of uniqueness, stability, accessibility and tolerance minimization. A case study is presented to demonstrate the capabilities and integration between the various modules of the system.

Similar content being viewed by others

References

Rong Y, Zhee Y (1999) Computer aided fixture design. Marcel Dekkar Inc., New York

Joshi S, Chang TC (1988) Graph-based heuristics for recognition of machined features. CAD 20:58–66

Nagraj HS, Gurumoorthy B (2002) Machinable volume extraction for automatic process planning. IIE Trans 34:393–410

Ong SK, Li WD, Nee AYC (2003) STEP-based integration of feature recognition and design by feature for manufacturing applications in a concurrent engineering environment. Int J Comput Appl Technol 18(1–4):78–92

Bhandarkar MP, Nagi R (2000) STEP-based feature extraction from STEP geometry for agile manufacturing. Comput Ind 41:3–24

Fu MW, Ong SK, Lu WF, Lee IBH, Nee AYC (2003) An approach to identify design and manufacturing features from a data exchanged part model. CAD 35:979–993

Bansal S (2006) A neutral format part model based integrated fixture planning system for minimum tolerances. PhD thesis, IIT Kanpur.

Nagarajan S, Reddy NV (2007) STEP-based automatic system for recognizing design and manufacturing features. Accepted for publication in International Journal of Production Research

SK Ong, AYC Nee (1997) Automatic setup planning in machining operation. J Mater Process Technol 63:151–156

Enchave J, Shah JJ (1999) Automatic set-up planning for 3-axis milling. Proceedings of the: 1999 Design Engineering Technical Conferences, Las Vegas, Nevada

Gologlu C (2004) A constraint-based operation sequencing for a knowledge-based process planning. J Intell Manuf 15(4):463–470 August 2004

Contini P, Tolio T (2004) Computer aided setup planning for machining centers configuration. Int J Prod Res 42:3473–3491

Paris D, Brissaud H (2005) Process planning strategy based on fixturing indicator & evaluation. Int J Adv Manuf Technol 25:913–922

Kale, Pande SS (1998) Intelligent setup generation for automated fixture planning. Proc. 8th international flexible automation and intelligent manufacturing conference, Portlad, USA, 545–557

Zhang Y, Peng G (2005) Development of an integrated system for setup planning & fixture design in CAPP. Proc. Of the 2005 IEEE/ASME International conf. on Advanced Intelligent Mechatronics, California (USA), 1401–1406

Asada H, BY AB (1985) Kinematic analysis of work-part fixturing for flexible assembly with automatically reconfigurable fixtures. IEEE J Robot Autom 2:86–93

Brost RC, Goldberg KY (1996) A complete algorithm for designing planer fixtures using modular components. IEEE Trans Robot Autom 12:31–46

Pelinescu DM, Wang MY (2002) Multiobjective optimal fixture layout design. Robot Comput-integr Manuf 18:365–392

Rong Y, Bai Y (1996) Machining accuracy analysis for computer aided fixture design verification. Transaction of ASME, J Manuf Sci Eng 118:289–299

Choudhuri SA, Demeter EC (1999) Tolerance analysis of machining fixture locators. Transaction of ASME, J Manuf Sci Eng 121:273–281

Wang MY (2002) Tolerance analysis for fixture layout design. Assem Autom 22:153–162

Marin RA, Ferreira PM (2003) Analysis of the influence of fixture location errors on the compliance of work part features to geometric tolerance specifications. Transaction of ASME, J Manuf Sci Eng 125:609–617

Bansal S, Malik P, Reddy NV, Saxena A (2007) Modular fixture planning for minimum 3D tolerances using a neutral part data exchange format. Int J Prod Res 46(6):1455–1476

Huang SH, Zhang HC, Oldham WJB (1997) Tolerance analysis for setup planning: A graph theoretical approach. Int J Prod Res 35(4):1107–1124

Huang SH, Liu Q (2003) Rigorous application of tolerance analysis in setup planning. Int J Adv Manuf Technol 3:196–207

SE Sarma, PK Wright (1996) Algorithms for the minimization of setups and tool changes in Simply fixturable components in milling. J Manuf Syst 15(2):95–112

Zhang YF, Nee AYC, Ong SK (1995) A hybrid approach for set-up planning. Int J Adv Manuf Technol 10:183–190

Zhang HC, Lin W (1999) A hybrid-graph approach for automated setup planning in CAPP. Robot Comput-integr Manuf 15:89–100

Sakurai H (1992) Automatic setup planning and fixture design for machining. J Manuf Syst 11(1):30–37

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bansal, S., Nagarajan, S. & Reddy, N.V. An integrated fixture planning system for minimum tolerances. Int J Adv Manuf Technol 38, 501–513 (2008). https://doi.org/10.1007/s00170-008-1416-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1416-6