Abstract

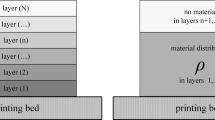

A component made up of a perfect combination of different materials (most often including homogeneous materials and three different types of heterogeneous materials, i.e., composite materials, functionally graded materials, and heterogeneous materials with a periodic microstructure) in its different portions for a specific application is considered to be a component made of a multiphase perfect material. To design and represent such components, a corresponding computer-aided design method and a CAD modeling method have been developed. Although, there is no existing manufacturing method and facility for such components. Their fabrication entails four steps described in this paper: analysis of the requirements of their manufacture; review of the currently available layered manufacturing, micro-fabrications, and hybrid manufacturing technologies; presentation of a new hybrid layered manufacturing technology (including its manufacturing process and the principle scheme of its corresponding manufacturing facilities); and implementation of the manufacturing simulation by means of virtual manufacturing technology.

Similar content being viewed by others

References

Chen KZ, Feng XA (2001) Towards design method for heterogeneous components. In: Proceedings of 13th international conference on engineering design, Glasgow, Scotland, UK, pp 445–52

Chen KZ, Feng XA (2003) Computer-aided design method for the components made of heterogeneous materials. Comput Aided Des 35:453–466

Chen KZ, Feng XA (2002) A modeling method of heterogeneous components. In: Proceedings of the international conference on manufacturing automation (ICMA2002), Hong Kong, pp 65–72

Chen KZ, Feng XA (2004) CAD modeling for the components made of multi heterogeneous materials and smart materials. Comput Aided Des 36:51–63

Zhu F, Chen KZ (2003) A CAD modeling system for the components made of multi heterogeneous materials. In: Proceedings of the 9th IEEE international conference on emerging technologies and factory automation (ETFA’2003), Lisbon, Portugal, vol. I, pp 559–565

Shin KH, Natu H, Dutta D, Mazumder J (2003) A method for the design and fabrication of heterogeneous objects. Mater Des 24:339–353

Berthelot JM (1999) Composite materials: mechanical behavior and structural analysis. Springer, New York

Barbero EJ (1998) Introduction to composite materials design. Taylor & Famcos, Ann Arbor, MI

Bhashyam S, Shin KH, Dutta D (2000) An integrated CAD system for design of heterogeneous objects. Rapid Prototyping J 6:119–135

Larson UD, Sigmund O, Bouwstra S (1997) Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio. J Microelectromech S 6:99–106

Silva ECN, Fonseca JSO, Kikuchi N (1997) Optimal design of piezoelectric microstructure. Comput Mech 19:397–410

Sigmund O, Torquato S (1997) Design of materials with extreme thermal expansion using a three-phase topology optimization method. J Mech Phys Solids 45(6):1037–1067

Bendsoe MP (1995) Optimization of structure topology, shape, and material. Springer, Berlin

Chua CK, Leong KF, Lim CS (2003) Rapid prototyping: principles and applications. World Scientific, Singapore

Prinz FB, Weiss LE (1998) Novel applications and implementations of shape deposition manufacturing. Naval Research Reviews, vol 1, Office of Naval Research, Washington, D.C.

Li XC, Choi H, Yang Y (2002) Micro rapid prototyping system for micro components. Thin Solid Films 420–421:515–523

Hur J, Lee K, Zhu H, Kim J (2002) Hybrid rapid prototyping system using machining and deposition. Comput Aided Des 34:741–754

Jenga JY, Lin MC (2001) Mold fabrication and modification using hybrid processes of selective laser cladding and milling. J Mater Process Technol 110:98–103

McGeough J (2002) Micromachining of engineering materials. Marcel Dekker, New York

Suh NP (1990) The principle of design. Oxford University Press, New York

Chen KZ, Feng XA (2004) Developing a manufacturing technology for components made of multi heterogeneous materials. In: Proceedings of the 3rd international conference on advanced manufacturing technology (ICAMT2004) Kuala Lumpur, Malaysia, pp 259–265

Hassani B, Hinton E (1999) Homogenization and structural topology optimization: theory, practice, and software. Springer, London

Madou MJ (2002) Fundamentals of microfabrication. CRC Press, Boca Raton

Devasenapathi A, Ng HW, Yu SCM, Indra AB (2002) Forming near net shape free-standing components by plasma spraying. Mater Lett 57:882–886

Wang F, Chen KZ, Feng XA (2004) Novel implementations of plasma spraying for fabricating components made of a multiphase perfect material. In: Proceedings of the 15th solid freeform fabrication symposium, Austin, Texas, USA, pp 293–303

Osaki K, Fujimoto S, Fukumasa O (2003) Application feasibility of high-performance-type plasma jet device to various material processes. Thin Solid Films 435:56–61

Chryssolouris G (1991) Laser machining theory and practice. Springer, New York

Clark MXR, Inc (2001) Time scales: what is a femtosecond? http://www.cmxr.com/Industrial/Handbook/Chapter2.htm

Meijer J (2004) Laser beam machining (LBM), state of the art and new opportunities. J Mater Process Technol 149:2–17

Rizvi HN, Apte P (2002) Developments in laser micro-machining techniques. J Mater Process Technol 127:206–210

Zhu F, Chen KZ, Feng XA (2004) Converting a CAD model into a manufacturing model for the component made of a multiphase perfect material. In: Proceedings of the 15th solid freeform fabrication symposium, Austin, Texas, USA, pp 532–543

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Chen, KZ., Feng, XY. et al. Developing a manufacturing technology for the components made of a multiphase perfect material. Int J Adv Manuf Technol 40, 837–846 (2009). https://doi.org/10.1007/s00170-008-1392-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1392-x