Abstract

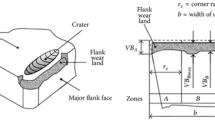

A vision system using high-resolution CCD camera and back-light was developed for the on-line measurement of nose wear of cutting tool inserts. Initial study showed that the system is sensitive to several factors in the work environment such as misalignment of cutting tool, presence of micro-dust particles, vibration and intensity variation of ambient light. An algorithm using Wiener filtering, median filtering, morphological operations and thresholding was developed to decrease the system error caused by these factors. A conforming method was used to overcome misalignment of the tool insert during offline and on-line measurement. The algorithm, combined with a subtraction method, was applied to measure the nose wear area of the inserts under different machining conditions.

Similar content being viewed by others

References

Sortino M (2003) Application of statistical filtering for optical detection of tool wear. Int J Mach Tools Manuf 43:493–497

Pfeifer T, Wiegers L (2000) Reliable tool wear monitoring by optimized image and illumination control in machine vision. Measurement 28:209–218

Jun Z, Jianxin D, Jianhua Z, Xing A (1997) Failure mechanisms of a whisker-reinforced ceramic tool when machining nickel-based alloys. Wear 208(1–2):220–225

Ezugwu EO, Bonney J (2004) Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools. J Mater Process Technol 153–154:1045–1050

Kassim AA, Mian Z, Mannan MA (2004) Connectivity oriented fast Hough transform for tool wear monitoring. Pattern Recognit 37:1925–1933

Lanzetta M (2001) A new flexible high-resolution vision sensor for tool condition monitoring. J Mater Process Technol 119:73–82

Kwon Y, Fischer GW (2003) A novel approach to quantifying tool wear and tool life measurements for optimal tool management. Int J Mach Tools Manuf 43:359–368

Dimla DES (2000) Sensor signals for tool wear monitoring in metal cutting operations-A review of methods. Int J Mach Tools Manuf 40:1073–1098

Yang MY, Kwon OD (1996) Crater wear measurement using computer vision and automatic focusing. J Mater Process Technol 58:362–367

Wang WH, Hong GS, Wong YS (2006) Flank wear measurement by a threshold independent method with sub-pixel accuracy. Int J Mach Tools Manuf 46(2):199–207

Kurada S, Bradley C (1997) A machine vision system for tool wear assessment. Tribol Int 30(4):294–304

Wong YS, Nee AYC, Li XQ, Riesdorf C (1997) Tool condition monitoring using laser scatter pattern. J Mater Process Technol 63:205–210

Jurkovic J, Korosec M, Kopac J (2005) New approach in tool wear measuring technique using CCD vision system. Int J Mach Tools Manuf 45:1023–1030

Dawson TG, Kurfess TR (2005) Quantification of tool wear using white light interferometry and three-dimensional computational metrology. Int J Mach Tools Manuf 45:591–596

Devillez A, Lesko S, Mozer W (2004) Cutting tool crater wear measurement with white light interferometry. Wear 256:56–65

Wang WH, Wong YS, Hong GS (2006) 3D measurement of crater wear by phase shifting method. Wear 261(2):164–171

Mannan MA, Kassim AA, Jing M (2000) Application of image and sound analysis techniques to monitor the condition of cutting tools. Pattern Recognit Lett 21:969–979

Choudhury SK, Bartarya G (2003) Role of temperature and surface finish in predicting tool wear using neural network and design of experiments. Int J Mach Tools Manuf 43:747–753

Galbiati LJ (1990) Machine vision and digital image processing fundamentals. Prentice-Hall, Upper Saddle River, NJ, USA

Gonzalez RC, Woods RE, Eddins SL (2004) Digital image processing using Matlab. Pearson-Prentice Hall, Upper Saddle River, NJ, USA

Gonzalez RC, Woods RE (2002) Digital image processing. Pearson Education, Upper Saddle River, NJ, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahabi, H.H., Ratnam, M.M. On-line monitoring of tool wear in turning operation in the presence of tool misalignment. Int J Adv Manuf Technol 38, 718–727 (2008). https://doi.org/10.1007/s00170-007-1119-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1119-4