Abstract

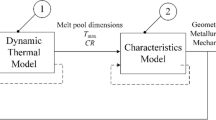

Laser spot welding as a joining method offers many outstanding advantages, such as localized heating and melting, high weld-strength-to-weld-size ratio, and minimal heat affected zone. These provide the benefits of low heat distortion, repeatability, ability to automate and high throughout that are always in demand in industry. An accurate knowledge of the temperature-time history of the weld pool is a prerequisite for reliable prediction of the weld dimensions, final microstructure and mechanical properties of the weld joint. Measurement of the weld thermal cycle in the laser weld pool is nearly impossible due to high peak temperature, rapid melting and solidification, and the complex flow of liquid metal within a small weld pool. Mathematical modeling of the laser spot welding process has emerged as a useful tool for the prediction of the temperature-time history and weld pool dimensions. However, the reliability of the predicted values of temperature history and weld dimensions significantly depends on the accuracy of the input parameters provided in such models. For example, the value of the absorption coefficient is a significant input parameter for modeling the laser spot welding process. However, the same is rarely available with adequate reliability and is also difficult to assign from scientific principles alone. This work presents a novel mathematical framework where the values of a set of uncertain input parameters for mathematical modeling are identified inherently by integrating a finite element based heat transfer simulation using adaptive volumetric heat source and a multivariate optimization algorithm.

Similar content being viewed by others

References

David SA, DebRoy T (1992) Current issues and problems in welding science. Science 257(5069):497–502

DebRoy T, David SA (1995) Physical processes in fusion welding. Rev Mod Phys 67(1):85–112

Tanriver U, Longobardi J, Latham WP, Kar A (2000) Effects of absorptiviy, shielding gas speed and contact media on sheet metal laser welding. Sci Technol Weld Join 5(5):310–316

Fuerschbach PW, Eisler GR (2002) Effect of laser spot weld energy and duration on melting and absorption. Sci Technol Weld Join 7(4):241–246

He X, DebRoy T, Fuerscbach PW (2003) Probing temperature during laser spot welding from vapor composition and modeling. J Appl Phys 94(10):6949–6958

He X, Fuerschbach PW, DebRoy T (2003) Heat transfer and fluid flow during laser spot welding of 304 stainless steel. J Phys, D Appl Phys 36(12):1388–1398

Pitscheneder W, DebRoy T, Mundra K, Ebner, R (1996) Role of sulfur and processing variables on the temporal evolution of weld pool geometry during multi-kilowatts laser welding of steels. Weld J 75(3):71s–80s

Zacharia T, David SA, Vitek JM, DebRoy T (1989) Heat transfer during Nd:YAG pulsed laser welding and its effect on solidification structure of austenitic stainless steels. Met Trans 20A:957–967

Mazumder J, Steen WM (1980) Heat transfer model for CW laser material processing. J Phys, D Appl Phys 51(2):941–947

Frewin R, Scott DA (1999) Finite element model of pulsed laser welding. Weld J 78(1):15s–22s

Chang WS, Na SJ (2002) A study on the prediction of the laser weld shape with varying heat source equations and thermal distortion of a small structure in micro-joining. J Mater Process Technol 120(1/3):208–214

De A, Maiti SK, Walsh CA, Bhadeshia HKDH (2003) Finite element simulation of laser spot welding. Sci Technol Weld Join 8(5):377–384

De A, Walsh CA, Maiti SK, Bhadeshia HKDH (2003) Prediction of cooling rate and microstructure in laser spot welds. Sci Technol Weld Join 8(6):391–399

De A, DebRoy T (2004) A smart model to determine effective thermal conductivity and viscosity in the weld pool. J Appl Phys 95(9):5230–5240

De A, DebRoy T (2004) Probing unknown welding parameters from convective heat transfer calculation and multivariate optimization. J Phys, D Appl Phys 37(1):140–150

Goldak J, Bibby M, Moore J, House R, Patel B (1986) Computer modeling of heat flow in welds. Metall Mater Trans 17B:587–600

Trivedi A, Bag S, De A (2007) Three dimensional transient heat conduction and thermomechancial analysis for laser spot welding using adaptive heat source. Sci Technol Weld Join 12(1):24–31

Hsu YF, Rubinsky B, Mahim K (1986) An inverse finite element method for the analysis of stationary arc welding processes. ASME J Heat Transfer 108(4):734–741

Rappaz M, Desbiolles JL, Drezet JM, Gandin CA, Jacot A, Thevoz P (1995) In: Cross M (ed) Proc. of 5th Int. Conf. on modeling of casting, welding and advanced solidification processes. The Minerals, Metals and Materials Society, Warrendale, PA, pp 449–457

Fonda RW, Lambrakos SG (2002) Analysis of friction stir welds using an inverse problem approach. Sci Technol Weld Join 7(3):177–181

Karkhin AV, Plochikhine VV, Bergmann HW (2002) Solution of inverse heat conduction problem for determining heat input, weld shape, and grain structure during laser welding. Sci Technol Weld Join 7(4):224–231

Trivedi A, Suman A, De A (2006) Integrating finite element based heat transfer analysis with ultivariate optimization for efficient weld pool modeling. ISIJ Int 46(2):267–275

Ozisik MN, Orlande HRB (2000) Inverse heat transfer. Taylor & Francis Inc., New York, p 37

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bag, S., Trivedi, A. & De, A. Use of a multivariate optimization algorithm to develop a self-consistent numerical heat transfer model for laser spot welding. Int J Adv Manuf Technol 38, 575–585 (2008). https://doi.org/10.1007/s00170-007-1101-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1101-1