Abstract

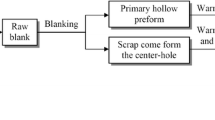

This paper describes a numerical and experimental investigation of preform design in non-axisymmetric warm forming in order to achieve a large reduction in the volume of flash. A titanium TA2 watch-case-like component was used as an example. Sixteen different shapes of hollow preforms were specially designed for finite-element simulation. Their diameters of the center-holes were designed based on the values of the diameters of end-face configurations of punches and ejectors. The corresponding thicknesses of the preforms were determined by the assumption of constant volume. Under the same processing conditions, the diameter of center-hole of the preform should be the inner diameter of ejector such that its volume of flash was able to be greatly reduced to 6% of the volume of the formed component whereas the volume of flash was approximately 25% in the conventional implementation. Experiments were subsequently performed to verify the simulation results. This study rationally demonstrates the success of the preform design for warm forming of non-axisymmetric components, and provides great improvement in the utilization of material in the bulk forming process. Thus, the achievement is a tremendous saving in materials, more than a fourfold, particularly for these rare and expensive alloys.

Similar content being viewed by others

References

Donachie MJ (2000) Titanium: a technical guide. ASM International, Materials Park, Ohio

Mitchell A (1998) Melting, casting and forging problems in titanium alloys. Mater Sci Eng A-Struct Mater Prop Microstruct Process 243:257–262

Prasad YVRK, Sasidhara S (1997) Hot working guide: a compendium of processing maps. ASM International, Materials Park, Ohio

Prasad YVRK, Seshacharyulu T (1998) Processing maps for hot working of titanium alloys. Mater Sci Eng A-Struct Mater Prop Microstruct Process 243:82–88

Fujikawa S, Yoshioka H, Shimanmura S (1992) Cold and warm forging application in the automotive industry. J Mater Process Technol 35:317–342

Hirschvogel M, Dommelen HV (1992) Some applications of cold and warm forging. J Mater Process Technol 35:343–356

Srinivasan K, Venugopal P (1993) Warm open-die extrusion of Ti-6Al-4V. J Mater Process Technol 38:265–278

Biswas SK, Knight WA (1975) Preform design for closed die forgings: experimental basis for computer aided design. Int J Mach Tool Des Res 15:179–193

Park JJ, Rebelo N, Kobayashi S (1983) A new approach to preform design in metal forming with the finite element method. Int J Mach Tool Des Res 23:71–79

Sheng S, Guo LY (1992) Preform design of axisymmetric forgings based on reverse simulation technique of die forging process. J Mater Process Technol 34:349–356

Han CS, Grandhi RV, Srinivasan R (1993) Optimum design of forging die using nonlinear finite element analysis. AIAA J 31:774–781

Oh SI, Yoon SM (1994) A new method of design blockers. Ann CIRP 43:245–248

Lapovok RY, Thomson PF (1995) An approach to preform design. Int J Mach. Tools Manuf 35:1537–1544

Takemasu T, Vazquez V, Painter B, Altan T (1996) Investigation of metal flow and preform optimization in flashless forging of a connecting rod. J Mater Process Technol 59:95–105

Vazquez V, Altan T (2000) Die design for flashless forging of complex parts. J Mater Process Technol 98:81–89

Hwang SM, Kobayashi S (1986) Preform design in disk forging. Int J Mach Tool Des Res 26:231–243

Zhao G, Zhao Z, Wang T, Grandhi RV (1998) Preform design of a generic turbine disk forging process. J Mater Process Technol 84:193–201

Sabroff AM, Boulger FW, Henning HJ (1968) Forging materials and practices, battelle memorial institute, Columbus, Ohio

Sheridan SA (1972) Forging design handbook. ASM, Metals Park, Ohio

Semiatin SL (1988) ASM Handbook Vol. 14 Forming and Forging. ASM, Metals Park, Ohio

Altan T, Nagpal V (1977) Impression and closed-die forging. Int Met Rev 22:322–340

Lange K, Meyer-Nolkemper H (1977) Close-die forming. Springer-Verlag, Berlin (In German)

Fluhrer J (2006) DEFORM-3D Version 6.0 User’s Manual, Scientific Forming Technologies Corporation. Columbus, Ohio

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, T.F., Chan, L.C. & Lee, T.C. Numerical and experimental investigation of preform design in non-axisymmetric warm forming. Int J Adv Manuf Technol 37, 908–919 (2008). https://doi.org/10.1007/s00170-007-1036-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-1036-6