Abstract

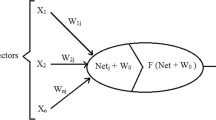

Tool wear prediction plays an important role in industry for higher productivity and product quality. Flank wear of cutting tools is often selected as the tool life criterion as it determines the diametric accuracy of machining, its stability and reliability. This paper focuses on two different models, namely, regression mathematical and artificial neural network (ANN) models for predicting tool wear. In the present work, flank wear is taken as the response (output) variable measured during milling, while cutting speed, feed and depth of cut are taken as input parameters. The Design of Experiments (DOE) technique is developed for three factors at five levels to conduct experiments. Experiments have been conducted for measuring tool wear based on the DOE technique in a universal milling machine on AISI 1020 steel using a carbide cutter. The experimental values are used in Six Sigma software for finding the coefficients to develop the regression model. The experimentally measured values are also used to train the feed forward back propagation artificial neural network (ANN) for prediction of tool wear. Predicted values of response by both models, i.e. regression and ANN are compared with the experimental values. The predictive neural network model was found to be capable of better predictions of tool flank wear within the trained range.

Similar content being viewed by others

References

Kwon Y, Fischer GW (2003) A novel approach to quantifying tool wear and tool life measurements for optimal tool management. Int J Mach Tools Manuf 43:359–368

Oraby SE, Hayhurst DR (2004) Tool life determination based on the measurement of wear and tool force ratio variation. Int J Mach Tools Manuf 44:1261–1269

Shao H, Wang HL, Zhao XM (2004) A cutting power model for tool wear monitoring in milling. Int J Mach Tools Manuf 44:1503–1509

Richetti A, Machado AR, Da Silva MB, Ezugwu EO, Bonney J (2004) Influence of the number of inserts for tool life evaluation in face milling of steels. Int J Mach Tools Manuf 44:695–700

Kuo RJ (2000) Multi-sensor integration for on-line monitoring tool wear estimation through artificial neural networks and fuzzy neural network. Eng Appl Artif Intell 13:249–261

Srinivasa Pai P, Nagabhushana TN, Ramakrishna Rao PK (2001) Tool wear estimation using resource allocation network. Int J Mach Tools Manuf 41:673–685

Choudhury SK, Bartarya G (2003) Role of temperature and surface finish in predicting tool wear using neural network and design of experiments. Int Journal of Mach Tools Manuf 43:747–753

Koshy P, Dumitrescu P, Ziada Y (2004) Novel methods for rapid assessment of tool performance in milling. Int J Mach Tools Manuf 44:1599–1605

Wang ZG, Wong YS, Rahman M (2005) High-speed milling of titanium alloys using binderless CBN tools. Int J Mach Tools Manuf 45:105–114

Choa S, Asfoura S, Onarb A, Kaundinyaa N (2005) Tool breakage detection using support vector machine learning a milling process. Int J Mach Tools Manuf 45:241–249

Huang P-T, Chen JC, Chou C-Y (1999) A statistical approach in detecting tool breakage in end milling operations. J Ind Technol 15:1–7

Srinivas J, Rama Kotaiah K (2005) Tool wear monitoring with indirect methods. Manuf Technol Today India 4:7–9

Chattopadhyay AB, Roy S (1996) Evaluation of wear of turning carbide inserts using neural networks. Int J Mach Tools Manuf 36:789–797

Pekelharing AJ (1978) The exit failure in interrupted cutting. CIRP Ann 27:5–10

Lou K-N, Lee C-T (1995) An intelligent on-line tool monitoring system in milling processes. IEEE T Neural Networ 1/95:2651–2656

Brezak D, Udiljak T, Mihoci K, Majetic D, Novakovic B, Kasac J (2004) Tool wear monitoring using radial basis function neural network. IEEE T Neural Networ 1/04:1859–1862

ISO (1993) Tool-life testing with single-point turning tools. ISO 3685:1993(E), 2nd edn. International Organization for Standards, Geneva

Shaw MC (2005) Metal cutting principles. Oxford University Press, New York

International Organization for Standardization ISO 8688 - 2 (1989), first edition. Tool life testing in milling - part 2, end milling

Quality America (1998), Software reference manual, D.O.E. - PC IV. Quality America Inc., Tucson, AZ, USA

Box GEP, Hunter WG (1978) Statistics for experiments: an introduction to design data analysis and model building. Wiley, New York

Eldem S, Barrow G (1976) Tool life in interrupted turning operations, Israel. J Technol 14:172–178

Bhatia SM, Pandey, PC, Shan HS (1979) Failure of cemented carbide tools in intermittent cutting. J Precision Eng 148–152

Baskar G, Ramamoorthy NV (2004) Artificial neural network: an efficient tool to simulate the profitability of state transport undertakings. Indian J Transport Manage 28(2):243–257

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palanisamy, P., Rajendran, I. & Shanmugasundaram, S. Prediction of tool wear using regression and ANN models in end-milling operation. Int J Adv Manuf Technol 37, 29–41 (2008). https://doi.org/10.1007/s00170-007-0948-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0948-5