Abstract

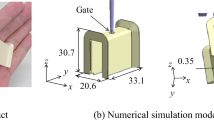

This study analyzes the contour distortions of polypropylene (PP) composite components applied to the interior of automobiles. Combining a trained radial basis network (RBN) [1] and a sequential quadratic programming (SQP) method [2], an optimal parameter setting of the injection molding process can be determined. The specimens are prepared under different injection molding conditions by varying melting temperatures, injection speeds and injection pressures of three computer-controlled progressive strokes. Minimizing the contour distortions is the objective of this study. Sixteen experimental runs based on a Taguchi orthogonal array table are utilized to train the RBN and the SQP method is applied to search for an optimal solution. In this study, the proposed algorithm yielded a better performance than the design of experiments (DOE) approach. In addition, the analysis of variance (ANOVA) is conducted to identify the significant factors for the contour distortions of the specimens.

Similar content being viewed by others

References

Chen S, Cowan CFN, Grant PM (1991) Orthogonal least squares learning algorithm for radial basis function networks. IEEE Trans Neural Netw 2(2):302–309

Fletcher R (1981) Practical methods of optimizations, vol. 1. Unconstrained Optimization, and vol. 2, Constrained Optimization. John Wiley and Sons Inc., New York

Liu SJ, Chang CY (2003) The influence of processing parameters on Thin-Wall Gas assisted injection molding of thermoplastic materials. J Reinf Plast Compos 22(8):711–731

Chien RD, Chen SC, Lee PH, Huang JS (2004) Study on the molding characteristics and mechanical properties of injection-molded foaming polypropylene parts. J Reinf Plast Compos 23(4):429–444

Ismail H, Suryadiansyah (2004) A comparative study of the effect of degradation on the properties of PP/NR and PP/RR Blends. Polym-Plast Technol Eng 43(2):319–340

Sain M, Suhara P, Law S, Bouilloux A (2005) A. Bouilloux, interface modification and mechanical properties of natural fiber-polyolefin composite products. J Reinf Plast Compos 24(2):121–130

Yao W, Jia Y, An L, Li B (2005) Elongational properties of biaxially oriented polypropylene with different processing properties. Polym-Plast Technol Eng 44(3):447–462

Modesti M, Lorenzetti A, Bon D, Besco S (2005) Effect of processing conditions on morphology and mechanical properties of compatibilized polypropylene nanocomposites. Polymer 46:10237–10245

Apichartpattanasiri S, Hay JN, Kukureka SN (2001) A study of the tribological behavior of polyamide 66 with varying injection-molding parameters. Wear 251:1557–1566

Jeng MC, Fung CP, Li TC (2002) The study on tribological properties of short glass fiber-reinforced PBT composites for various injection molding process parameters. Wear 252:934–945

Fung CP, Hwang JR, Hsu CC (2003) The effect of injection molding process parameters on the tensile properties of short glass fiber-reinforced PBT. Polym-Plast Technol Eng 42:45–63

Das P (1999) Concurrent optimization of multi-response product performance. Qual Eng 11:365–368

Tong L-I, Su C-T, Wang C-H (1997) The optimization of multi-response problems in Taguchi method. Int J Qual Reliab Manage 14:367–380

Liao H-C (2004) A data envelopment analysis method for optimizing multi-response problem with censored data in the Taguchi method. Comput Indust Eng 46:817–835

Su C-T, Chiang T-L (2003) Optimizing the IC wire bonding process using a neural network/genetic algorithms approach. J Intell Manuf 14(2):229–238, April

Hsieh K-L (2005) Parameter optimization of a multi-response process for lead frame manufacturing by employing artificial neural networks. Int J Adv Manuf Technol, DOI 10.1007/s00170-004-2383-1

Huang C-C, Tang T-T (2005) Parameter optimization in melt spinning by neural networks and genetic algorithms. Int J Adv Manuf Technol, DOI 10.1007/s00170-004-2302-5

Shie J-R (2006) Optimization of dry machining parameters for high-purity graphite in end-milling process by artificial neural networks: a case study. Mater Manuf Process 21:838–845

Briceno FJ, El-Mounayri H, Mukhopadhyay S (2002) Selecting an artificial neural network for efficient modeling and accurate simulation of the milling process. Mach Tools Manuf 42:663–674

Tsai H-M, Wang P-J (2001) Predictions on surface finish in electrical discharge machining based upon neural network models. Mach Tools Manuf 41:1385–1403

Kim B, Park K (2005) Modeling plasma etching process using a radial basis function. Microelectron Eng 77:150–157

Neural Network Toolbox User’s Guide Version. 3.0 (1997) The MathWorks, Inc., 24 Prime Park Way, Natick, MA 01760-1500

Douglas CM (1997) Design and analysis of experiments, 4th edn. John Wiley & Sons, Inc., pp 101–630

Ranjit KR (1990) A primer on the Taguchi Method. Van Nostrand Reinhold, New York

Myers RH, Montgomery DC (2002) Response surface methodology, 2nd edn. John Wiley and Sons Inc., New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shie, JR. Optimization of injection molding process for contour distortions of polypropylene composite components by a radial basis neural network. Int J Adv Manuf Technol 36, 1091–1103 (2008). https://doi.org/10.1007/s00170-007-0940-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0940-0