Abstract

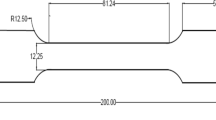

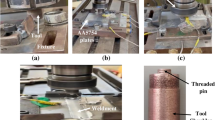

In the present work, application of the Taguchi method in combination with grey relational analysis has been applied for solving multiple criteria (objective) optimization problem in submerged arc welding (SAW). A grey relational grade evaluated with grey relational analysis has been adopted to reveal an optimal parameter combination in order to obtain acceptable features of weld quality characteristics in submerged arc bead-on-plate welding. The idea of slag utilization, in subsequent runs, after mixing it with fresh unmelted flux, has been introduced. The parentage of slag in the mixture of fresh flux and fused flux (slag) has been denoted as slag-mix%. Apart from two conventional process parameters: welding current and flux basicity index, the study aimed at using varying percentages of slag-mix, treated as another process variable, to show the extent of acceptability of using slag-mix in conventional SAW processes, without sacrificing any characteristic features of weld bead geometry and HAZ, within the experimental domain. The quality characteristics associated with bead geometry and HAZ were bead width, reinforcement, depth of penetration and HAZ width. Using grey relational grade as performance index, we have performed parametric optimization yielding the desired features of bead geometry and HAZ. Predicted results have been verified with confirmatory experiments, showing good agreement. This proves the utility of the proposed method for quality improvement in SAW process and provides the maximum (optimum) amount of slag-mix that can be consumed in the SAW process without any negative effect on characteristic features of the quality of the weldment in terms of bead geometry.

Similar content being viewed by others

References

Gunaraj V, Murugan N (2000) “Prediction and optimization of weld bead volume for the submerged arc process-Part-1”. Welding Research Supplement :286–294

Gunaraj V, Murugan N (2000) “Prediction and optimization of weld bead volume for the submerged arc process-Part-2”. Welding Research Supplement :331–338

Beck HP, Jackson AR (1996) “Recycling of SAW slag proves reliable and repeatable”. Welding Journal :51–54

Livshit LG, Shiryaev AI (1960) “A new ceramic flux for hard facing”. Weld Prod :25–29 January

Moi SC, Bandyopadhyay A, Pal PK (2001) “Submerged arc welding with a mixture of fresh flux and fused slag”. Proceedings of National Seminar on Advances in Material & Processing, IIT Roorkee

Pal PK, Bandyopadhyay A, Bala AK (2001) “Some aspects of submerged arc welding with mixture of fresh flux and fused slag”. Proceedings of International Conference, BUET, Dhaka, Bangladesh

Rowlands H, Antony J, Knowles G (2000) “An application of experimental design for process optimization”. TQM Mag 12(2):78–83

Antony J, Antony F (2001) “Teaching the Taguchi method to industrial engineers”. Work Study 50(4):141–149

Maghsoodloo S, Ozdemir G, Jordan V, Huang C-H (2004) “Strengths and limitations of Taguchi’s contributions to quality, manufacturing, and process engineering”. J Manuf Syst 23(2):73–126

Lim S-H, Lee C-M, Chung WJ (2006) “A study on the optimal cutting condition of a high speed feeding type laser cutting machine by using Taguchi method”. Int J Precis Eng Manuf 7(1):18–23

Unal R, Dean Edwin B (1991) “Taguchi Approach to Design Optimization for Quality and Cost: An Overview”. Presented at the Annual Conference of the International Society of Parametric Analysis

Yang WH, Tarng YS (1998) “Design optimization of cutting parameters for turing operations based on the Taguchi method”. J Mater Process Technol 84:122–129

Tarng YS, Juang SC, Chang CH (2002) “The use of grey-based Taguchi methods to determine submerged arc welding process parameters in hardfacing”. J Mater Process Technol 128:1–6

Lin CL (2004) “Use of the Taguchi method and grey relational analysis to optimize turing operations with multiple performance characteristics”. Mater Manuf Process 19(2):209–220

Davis OL (1978) “Design and analysis of industrial experiments”. Longman, New York

Datta S, Sundar M, Bandyopadhyay A, Pal PK, Nandi G, Roy SC (2005) “Effect of electrode stick out on quality and performance of submerged arc welding-experimental and statistical analyses”. Proceedings of the International Conference on Mechanical Engineering, held on 28–30 December, at Dhaka, Bangladesh

Kim IS, Son JS, Park CE, Kim IJ, Kim HH (2005) “An investigation into an intelligent system for predicting bead geometry in GMA welding process”. J Mater Process Technol 159:113–118

Myers R, Montgomery D “Response Surface Methodology”. Wiley, New York, NY

Asiabanpour B, Palmer K, Khoshnevis B (2004) “An experimental study of surface quality and dimensional accuracy for selective inhibition of sintering”. Rapid Prototyping J 10(3):181–192

MINITAB release 13.1 (user manual)

Acknowledgements

Authors would like to acknowledge Sri Subhas Chandra Moi, Ex. PG student, Department of Mechanical Engineering, Jadavpur University.

Authors are also grateful to the reviewers for their valuable advice for significant modification and better presentation of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Datta, S., Bandyopadhyay, A. & Pal, P.K. Solving multi-criteria optimization problem in submerged arc welding consuming a mixture of fresh flux and fused slag. Int J Adv Manuf Technol 35, 935–942 (2008). https://doi.org/10.1007/s00170-006-0776-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0776-z