Abstract

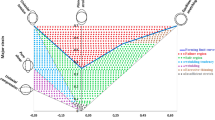

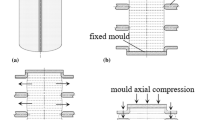

In this study, part springback and metal flow caused by punch penetration into a sheet was investigated by punching circular test specimens with concentric circular tools. Strain gauges were bonded on the upper surface of the specimens at radial distances varying from 2 mm to 10 mm from the cutting edge of the punch. The experiments were used to validate a finite element model (FEM) valid for numerical simulation of sheet-metal punching processes. Damage and crack propagation were taken into account by means of an elastoplastic constitutive law. The main difficulty encountered in simulating this operation is describing the behaviour of the sheet continuously from the beginning of the operation up to the total rupture. The choice of a behaviour law is crucial, since each successive step in the whole process has to be described accurately. In this investigation, an elastoplastic behaviour law coupled with damage was retained to describe the progressive damage accumulation in the workpieces. During the analysis, the initiation of a crack is assumed to occur at any point in the structure where the damage reaches its critical value D c . The crack propagation is simulated by the propagation of a completely damaged area. This is taken into account in the FEM by a decrease in the stiffness of the broken elements. The numerical results obtained by the simulation were compared with the experimental ones in order to verify the validity of the proposed FEM.

Similar content being viewed by others

References

ABAQUS. HKS theory manual, Version 6.4

ABAQUS User’s conference (1993) Writing a (V). Umat, Aachen, Germany, June

Criesfield MA (1991) Non linear finite element analysis of solids and structures, vol. 1. Wiley

Dufailly J (1980) Modélisation mécanique et identification de l’endommagement plastique des métaux. Thése de Docteur de 3éme cycle. Univ. Pierre et Marie Curie, Paris 6

El Menni MM, Dubois, Gelin M (1993) Traitement de problémes numériques liés à la modélisation par éléments finis du processus de découpages des métaux. Strucome 568–578

Hambli Ridha (1996) Etude expérimentale, numérique et théorique du découpage des tôles en vue de l’optimisation du procédé. Doctoral thesis, ENSAM d’Angers, 15 Oct

Homsi M, Wronski M, et Roelandt JM (1994) Modélisation numérique de la coupe. Strucome 677–690

Hartley P, Pillinger I, Sturgess C (1992) Numerical modeling of material deformation processes: research, development and applications. Springer, Berlin Heidelberg New York

Kasuga Y, Tsutsumi S, Mori T (1979) Investigation into shearing process of ductile sheet metals. Mem Fac Eng Nagoya Univ Japan. 1–46

Lemaître J, Chaboche JL (1988) Mécanique des matériaux solides, 2nd edn. Dunod

Marques JMMC (1984) Stress computation in elastoplasticity. Eng Comput 1

Maillard A (1991) Etude expérimentale et théorique du découpage. Doctoral thesis, Université de Technologie de Compiégne

Popat PB, Ghosh A, Kishore NN (1989) Finite element analysis of the blanking process. J Mech Working Tech 269–282

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hambli, R. Metal flow prediction during sheet-metal punching process using the finite element method. Int J Adv Manuf Technol 33, 1106–1113 (2007). https://doi.org/10.1007/s00170-006-0549-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0549-8