Abstract

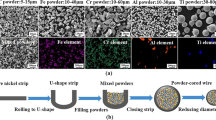

The property of alloy parts can be adjusted conveniently if alloy element powders are used for manufacturing alloy parts by indirect selective laser sintering (SLS), but there have been no reports in this field. Fe, Cu, Ni, C composite powders of two compositions were obtained through a 3D blending way in this paper. Green parts of above composite powder were manufactured by indirect SLS. Then, Cu matrix Fe-Cu-Ni-C alloy composites were produced after green parts had been depolymerized, high temperature sintered and infiltrated by molten Cu. The post-processing of green parts, microstructure and mechanical properties of alloy composites were investigated. The results show: Ni, Cu and C diffuse into γ-Fe when green parts are being sintered at high temperature and the distributing non-uniformity of alloy elements is eliminated basically; at room temperature, alloy composite microstructures are composed of lower bainite, α-Cu precipitated out of γ-Fe and Fe-Ni after they have been solution treated at 930°C and held at 350°C for 1 h later; the yield strength of alloy composites is near to 400 MPa and the elongation is under 3%. It can be used for manufacturing injection mold or other functional parts by indirect SLS.

Similar content being viewed by others

References

Kumar S (2003) Selective laser sintering: a qualitative and objective approach. JOM 55(10):43–47

Levy GN, Schindel R (2002) Overview of layer manufacturing technologies, opportunities, options and applications. Proc Inst Mech Eng B 216(12):1621–1634

Goode E (2003) Selective laser sintering system & materials. Adv Mater Process 1(161):66–67

Ódonnchadha B, Tansey A (2004) A note on rapid metal composite tooling by selective laser sintering. J Mater Process Technol 153–154:28–34

Kruth JP, Wang X, Laoui T, Froyen L (2003) Lasers and materials in selective laser sintering. Assem Autom 23(4):357–371

Uzunsoy D, Chang ITH, Bowen P (2003) Fracture behaviour of selective laser sintered rapidsteel 2.0 under static and dynamic loading. Mater Sci Technol 19(7):897–901

Anonymous (2000) P/M stainless steel alloy made for rapid prototyping. Adv Mater Process 158(5):16

Nelson JC, Xue S, Barlow JW et al (1993) Model of the selective laser sintering of bisphenol-a polycarbonate. Ind Eng Chem Res 32:2305–2317

Gibson Ian, Dongping Shi (1997) Material properties and fabrication parameters in selective laser sintering process. Rapid Prototyping J 4(3):129–136

Vail NK, Balasubramanian B, Barlow JW et al (1996) A thermal model of polymer degradation during selective laser sintering of polymer coated ceramic powders. Rapid Prototyping J 2(3):24–40

Bear J (1972) Dynamics of Fluids in porous media. Dover Publications, New York

Chen H (1994) Viscosity measurement. China Metrology Press, Beijing (in Chinese)

Xue R (2002) Powder metallurgy structural material. Center South University Press, Changsha (in Chinese)

Wu C (2000) Metal materials. Metallurgy Industry Press, Beijing (in Chinese)

Fang H (1999) Bainite transition. Science Press, Beijing (in Chinese)

Kang D, Guo C (1992) Microstructure transition pictures and property charts of engineering steel. Mechanical Industry Press, Beijing (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J.H., Shi, Y.S., Chen, K.H. et al. Research on manufacturing Cu matrix Fe-Cu-Ni-C alloy composite parts by indirect selective laser sintering. Int J Adv Manuf Technol 33, 693–697 (2007). https://doi.org/10.1007/s00170-006-0493-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0493-7