Abstract

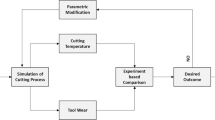

The machining center methodology is widely applied to production systems within the fast-developing processing industry. The automated machining center can simultaneously perform certain processes, such as milling, drilling, boring, and reaming, on the same machine at the same time, and manufactures limited quantities of multiple-type products. These products usually have numerically important quality characteristics with high accuracy. However, a machining center is unable to measure process capability on its own. Thus, we reflect the process capability of a machining center by measuring the quality characteristics of its processing products. In this paper, we propose the three integrated process capability indices (PCIs) C mcp , C mca , and C mcpm to evaluate the integrated process precision, accuracy, and actual capability respectively. Furthermore, we develop a process capability monitoring figure (PCMF), which not only displays the status of the process precision and accuracy by the color management method [1], but it also forecasts the integrated process capability of the next productive time (batch) through the analysis of time series. Using the PCMF, engineers will be assisted with tasks such as monitoring the process quality, deciding the period of the borer’s replacement, and designing the process parameters.

Similar content being viewed by others

References

Chrysler Corporation, Ford Motor Company, General Motors Corporation (1998) Quality system requirements, QS9000, 3rd edn. Automotive Industry Action Group, Southfield, Michigan

Kane VE (1986) Process capability indices. J Qual Technol 18(1):41–52

Pearn WL, Kotz S, Johnson NL (1992) Distributional and inferential properties of process capability indices. J Qual Technol 24(4):216–231

Chan LK, Cheng SW, Spring FA (1998) A new measure of process capability: Cpm. J Qual Technol 20(3):162–175

Ruczinski (1996) The relation between Cpm and the degree of inclusion. Doctoral dissertation, University of Wurzburg, Wurzburg, Germany

Singhal SC (1991) Multi-process performance analysis chart (MPPAC) with capability zones. Qual Eng 4(1):75–81

Chen H (1994) A multivariate process capability index over a rectangular solid tolerance zone. Stat Sin 4:749–758

Boyles RA (1996) Multivariate process analysis with lattice data. Technometrics 38(1):37–49

Vännman K, Deleryd M (1999) Process capability plots—a quality improvement tool. Qual Reliab Eng Int 15(3):213–217

Chen KS, Huang ML, Li RK (2001) Process capability analysis for an entire product. Int J Prod Res 39(17):4077–4087

Huang ML, Chen KS (2003) Capability analysis for a multi-process product with bilateral specifications. Int J Adv Manuf Technol 21(10–11):801–806

Sung WP, Chen KS (2004) An analytical method for the process capability of a precision component of an instrument. Int J Adv Manuf Technol 24(1–2):126–131

Boyles RA (1991) The Taguchi capability index. J Qual Technol 23(1):17–26

Hung MC (2003) Integrated process capability analysis. Dissertation, National Taiwan University of Science and Technology, Taiwan, ROC

Huang CC (2003) Evaluation model for process capability of machining. Dissertation, National Chin-Yi Institute of Technology, Taiwan, ROC

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, K.T., Sheu, S.H. & Chen, K.S. The evaluation of process capability for a machining center. Int J Adv Manuf Technol 33, 505–510 (2007). https://doi.org/10.1007/s00170-006-0481-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0481-y