Abstract

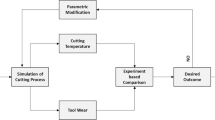

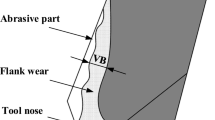

Tool wear monitoring is an integral part of modern CNC machine control. Cutting tools must be periodically checked for possible or actual premature failures, and it is necessary to record the cutting history for a tool’s full life of utilisation. This means that an on-line monitoring system would be of great benefit to overall process control in manufacturing systems. Computer vision has already shown promise as a candidate technology for this task. In this paper, we describe the use of digital image processing techniques in the analysis of images of worn cutting tools in order to assess their degree of wear and thus remaining useful life. It is shown that a processing strategy using a variety of image texture measures allows for effective visualisation and assessment of tool wear, and indicates good correlation with the expected wear characteristics.

Similar content being viewed by others

References

DeGarmo EP, Black JT, Kohser RA (1988) Materials and processes in manufacturing. Macmillan, Prentice-Hall, Upper Saddle River, NJ

Li X (2002) A brief review: acoustic emission method for tool wear monitoring during turning. Int J Mach Tool Manuf 42(2):157–165

Dimla DE (2002) The correlation of vibration signal features to cutting tool wear in a metal turning operation. Int J Adv Manuf Technol 19(10):705–713

Ryabov O, Mori K (2001) Wear sensor integrated cutting tool for turning. In: First ISA/IEEE Sensors for Industry Conference, Rosemont, IL, pp 84–88

Kaye JE, Yan DH, Popplewell N, Balakrishnan S (1995) Predicting tool flank wear using spindle speed change. Int J Mach Tool Manuf 35(9):1309–1320

Ertunc HM, Oysu C (2004) Drill wear monitoring using cutting force signals. Mechatronics 14(5):533–548

Giusti F, Santochi M, Tantussi G (1984) A flexible tool wear sensor for NC lathes. Ann CIRP 33(1):229–231

Otto T, Kurik L (2000) Digital Tool Wear Measuring Video System. In: 2nd International Conference of Danube Adria Association for Automation & Manufacturing (DAAAM), Tallin, Estonia, pp 144–146

ISO 3685 (1993) Tool-life testing with single-point turning tools, 2nd edn. International Organisation for Standardisation, CH-1211 Geneva 20, Switzerland (http://www.iso.ord)

Koren K (1978) Flank wear model of cutting tools using control theory. J Eng Ind 100(1):103–109

Kwon Y, Fischer GW (2003) A novel approach to quantifying tool wear and tool life measurements for optimal tool management. Int J Mach Tool Manuf 43(4):359–368

Kurada S, Bradley C (1997) A review of machine vision sensors for tool condition monitoring. Comput Ind 34(1):55–72

Kurada S, Bradley C (1997) A machine vision system for tool wear assessment. Tribology Int 30(4):295–304

Bradley C, Wong YS (2001) Surface texture indicators of tool wear – a machine vision approach. Int J Adv Manuf Technol 17(6):435–443

Yamashina H, Okumura S (1996) A machine vision system for measuring wear and chipping of drilling tools. J Intell Manuf 7(4):319–327

Haralick R, Shanmugam K, Dinstein I (1973) Textural features for image classification. IEEE Trans Syst Man Cybern 3(6):610–621

United States National Institutes of Health (2004) ImageJ 1(32). http://rsb.info.nih.gov/ij/

Iivarinen J (2000) Surface defect detection with histogram-based texture features. In: Conference on Intelligent Robots and Computer Vision XIX: Algorithms, Techniques, and Active Vision, Boston, MA, pp 140–145

Lee BY, Yu SF, Juan H (2004) The model of surface roughness inspection by vision system in turning. Mechatronics 14(1):129–141

Tsai D-M, Chen J-J, Chen J-F (1998) Vision system for surface roughness assessment using neural networks. Int J Adv Manuf Technol 14(6):412–422

Nixon M, Aguado A (2001) Feature extraction and image processing. Butterworth-Heinemann, Oxford, UK

Liu S-S, Jernigan M (1990) Texture analysis and discrimination in additive noise. Comput Vis Graph Image Process 49(1):52–67

Russ JC (1990) Processing images with a local Hurst operator to reveal textural differences. J. Comput Assist Microscopy 2(4):249–257

Sarkar N, Chaudhuri BB (1994) An efficient differential box-counting approach to compute fractal dimension of image. IEEE Trans Syst Man Cybernetics 24(1):115–120

Bonetto RD, Forlerer E, Ladaga JL (2002) Texture characterization of digital images which have a periodicity or a quasi-periodicity. Meas Sci Tech 13(1):1458–1466

Siniawski MT, Harris SJ, Wang Q, Liu S (2003) Wear initiation of 52100 steel sliding against a thin boron carbide coating. Tribology Lett 15(1):29–41

Chandrasekhar R, Attikiouzel Y (2000) New range-based neighbourhood operator for extracting edge and texture information from mammograms for subsequent image segmentation and analysis. IEE Proc Sci Meas Technol 147(6):408–413

Jain AK (1989) Fundamentals of digital image processing. Prentice-Hall, New York

Jain R, Kasturi R, Schunck B (1995) Machine vision. McGraw-Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kerr, D., Pengilley, J. & Garwood, R. Assessment and visualisation of machine tool wear using computer vision. Int J Adv Manuf Technol 28, 781–791 (2006). https://doi.org/10.1007/s00170-004-2420-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2420-0