Abstract

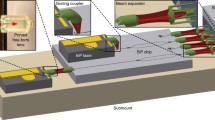

In this paper, a flexible microassembly system based on hybrid manipulation scheme is proposed to apply to the assembly of photonics components such as lensed optical fiber ferrules and laser diode (LD) pumps. In order to achieve both high precision and dexterity in microassembly, we propose a hybrid microassembly system with sensory feedbacks of vision and force. This system consists of the distributed six degrees of freedom (DOF) micromanipulation units, the stereomicroscope, and haptic interface for the force feedback-based microassembly. A hybrid assembly method, which combines the vision-based microassembly and the scaled teleoperated microassembly with force feedback, is proposed. The feasibility of the proposed method is investigated via experimental studies for assembling micro-optoelectrical components. Experimental results show that the hybrid microassembly system is feasible for applications to the assembly of photonic components in the commercial market with better flexibility and efficiency.

Similar content being viewed by others

References

Ando N, Korondi P, Hashimoto H (2001) Development of micromanipulator and haptic interface for networked micromanipulation. IEEE/ASME Trans Mechatron 6(4):417–427

Fatikow S, Seyfried J, Fahlbusch S, Buerkle A, Schmoeckel F (2000) A flexible microrobot-based microassembly station. J Intell Robot Syst 27:135–169

Kim DH, Kim B, Kang HJ (2004) Development of a piezoelectric polymer-based sensorized microgripper for micromanipulation and microassembly. Microsyst Technol 10(4):275–280

Zhou Y, Nelson BJ, Vikramaditya B (2000) Integrating optical force sensing and visual serving for microassembly. J Intell Robot Syst 28(3):259–276

Kim DH, Kim K, Kim KY, Cha SM (2001) Dexterous teleoperation for micro parts handing based on haptic/visual interface. Proceedings of the 2001 IEEE International Symposium on Micromechatronics and Human Science, Nagoya, Japan, 2001, pp 211–217

Popa D, Kang BH, Sin J, Zou J (2002) Reconfigurable microassembly system for photonics applications. Proceedings of the 2002 IEEE International Conference on Robotics and Automation, Washington, DC, May 2002, pp 1495–1500

Nelson BJ, Zhou Y, Vikramaditya B (1998) Sensor-based microassembly of hybrid MEMS device. IEEE Control Syst 18(6):35–45

Yang G, Gaines JA, Nelson BJ (2003) A supervisory wafer-level 3D microassembly system for hybrid MEMS fabrication. J Intell Robot Syst 37:43–68

Song EH, Kim DH, Kim K, Lee J (2001) Intelligent user interface for teleoperated microassembly. Proceedings of the 2001 International Conference on Control, Automation and Systems, Jeju, Korea, 17–21 October 2001, pp 784–788

Matrox Electronic Systems Ltd. (2001) Matrox imaging library version 7.0 user guide. Matrox Electronic Systems, Dorval, Canada

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, B., Kang, H., Kim, DH. et al. A flexible microassembly system based on hybrid manipulation scheme for manufacturing photonics components. Int J Adv Manuf Technol 28, 379–386 (2006). https://doi.org/10.1007/s00170-004-2360-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2360-8