Abstract

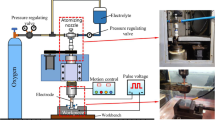

In this study, a composite processing technology combined with supersonic and electrochemical machining is adapted to etch copper. Rod copper of diameter 3.0 mm is selected as a sample material. A series of experiments of supersonic-aided electrolysis by agitating anode, and electrolyte were carried out to investigate performance for copper etching. Faster metal removal rate can be achieved in supersonic-aided electrolysis machining by agitating either the anode or electrolyte. Removal rate can be raised up to 65% by supersonic-aided electrolysis by agitation both of anode and electrolyte. Deposition speed of cathode is lower in supersonic-aided electrolysis. Machined surface roughness of workpiece by supersonic-aided electrolysis is much better than no agitation.

Similar content being viewed by others

References

Pan C-T, Yang H, Wang H-J, Chou M-C (1999) Behavior of the developing process for ultra-deep microstructures. Sens Mater 11(6):339–347

Yang H, Kang S-W (2000) Improvement of thickness uniformity in nickel electroforming for the LIGA process. Int J Mach Tools Manuf 40:1065–1072

Yang H, Pan C-T, Chou M-C (2001) Ultra-fine machining tool/molds by LIGA technology. J Micromech Microeng 11(2):94–99

van Kan JA, Sanchez IL, Xu B, Osipowicz T, Watt F (1999) Micromachining using focused high energy ion beams: deep ion beam lithography. Nucl Instrum Meth Phys Res B 148:1085–1089

Bhattacharyya B, Doloi B, Sridhar PS (2001) Electrochemical micro-machining: new possibilities for micro-manufacturing. J Mater Process Technol 113:301–305

Pei ZJ, Ferreira PM, Kapoor SG, Hasekorn M (1995) Rotary ultrasonic machining for face milling of ceramics. Int J Tools Manuf 35(7):1033–1046

Zhang JH, Lee TC, Wu CL, Tang CY (2002) Surface integrity and modification of electro-discharge machined alumina-based ceramic composite. J Mater Process Technol 123:75–79

Zhang QH, Zhang JH, Jia ZX, Sun JL (1999) Material removal-rate analysis in the ultrasonic machining of engineering ceramics. J Mater Process Technol 88:180–184

Yan BH, Wang AC, Hang CY, Huang FY (2002) Study of precision micro-holes in borosilicate glass using micro EDM combined with micro ultrasonic vibration machining. Int J Mach Tools Manuf 42:1105–1112

Guo ZN, Lee TC, Yue TM, Lau WS (1997) A study of ultrasonic-aided wire electrical discharge machining. J Mater Process Technol 63:823–828

Zhou M, Wang XJ, Ngoi BKA, Gan JGK (2002) Brittle-ductile transition in the diamond cutting of glasses with the aided of ultrasonic vibration. J Mater Process Technol 121:243–251

Roetzel W, Spang B, Luo X, Das SK (1998) Propagation of the third sound wave in fluid: hypothesis and theoretical foundation. Int J Heat Mass Trans 41:2769–2780

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weng, FT. A study of supersonic-aided electrolysis. Int J Adv Manuf Technol 25, 480–483 (2005). https://doi.org/10.1007/s00170-003-1862-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1862-0